Full-automatic four-port recycling machine and using method thereof

A recovery machine and fully automatic technology, which is applied in the direction of refrigerators, refrigeration components, lighting and heating equipment, etc., can solve the problems of motor burnout, crash, and easy occurrence of liquid shock, so as to increase the fan speed, improve cooling effect, and avoid liquid hit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

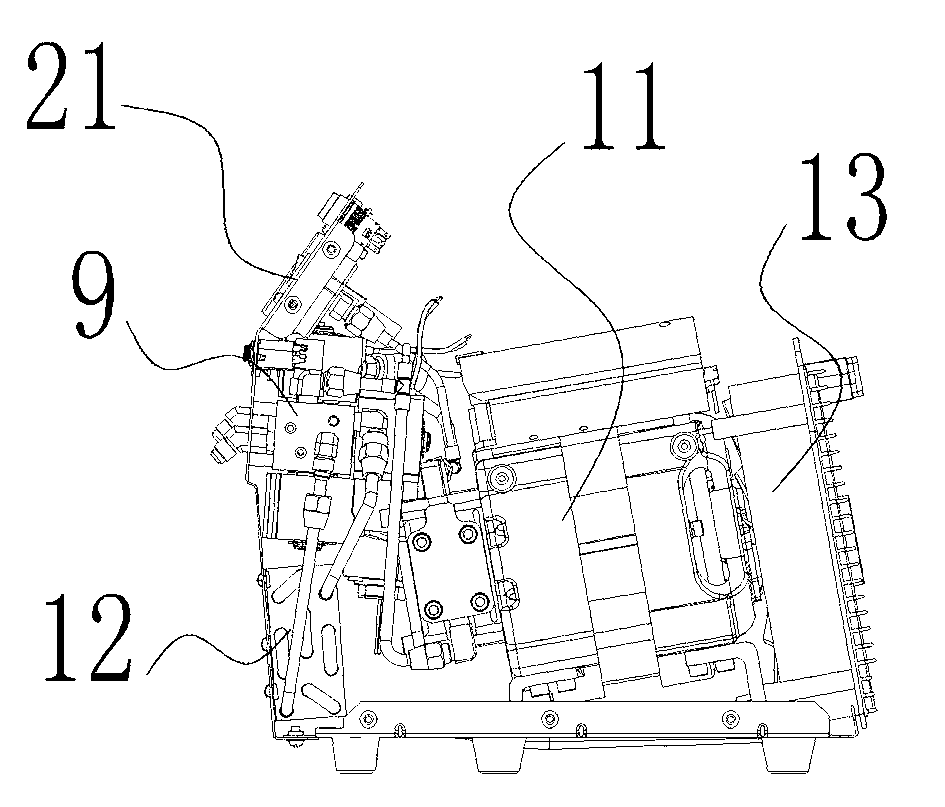

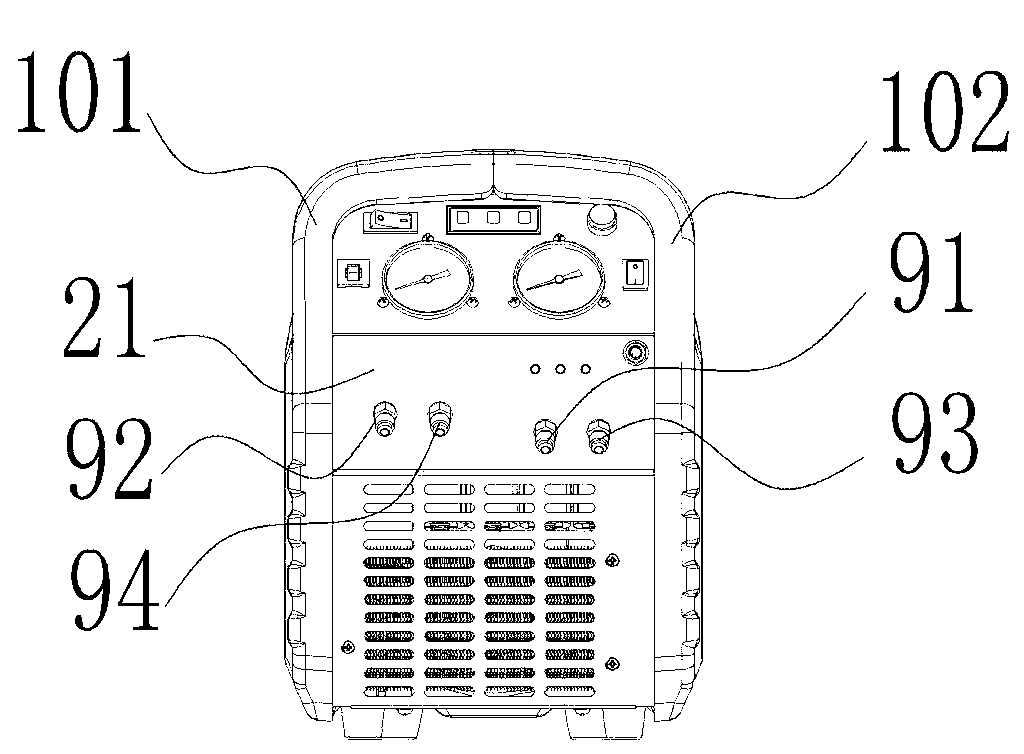

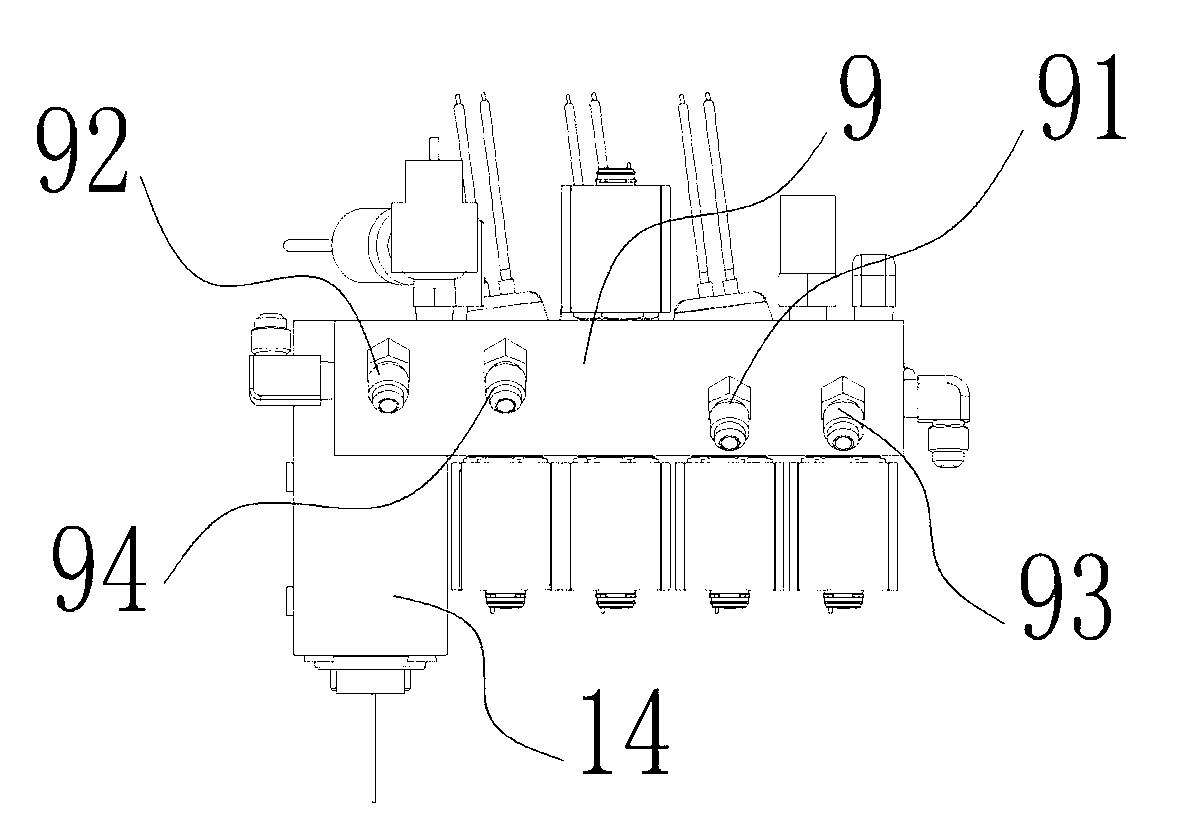

[0042] Such as figure 2 As shown, a fully automatic four-port recovery machine of the present invention includes a shell formed by docking the left shell 101 and the right shell 102, and is sandwiched between the front ends of the left shell 101 and the right shell 102. A piece of operation panel 21, the operation panel 21 faces obliquely upwards, on the operation panel 21 is equipped with a power switch electrically connected to the control circuit, a manual self-clearing switch, a work indicator light, a start button, a shutdown fault work indicator light, a high pressure oil filling Pressure gauge, low-pressure oil-filled pressure gauge and overload protector. Such as figure 1 As shown, a control valve 9, a compressor 11, a condenser 12 and a fan 13 are connected through copper pipelines in the casing, and the control valve 9 is fixed on the rear side of the operation panel 21, as image 3 As shown, the gaseous input port 91 of the recovery machine, the liquid input por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com