Novel coal sample collecting device

A collection device and coal sample technology, applied in the direction of sampling device, etc., can solve problems such as no ventilation, large error, inaccurate gas content data, etc., and achieve the effect of simple operation, high collection efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

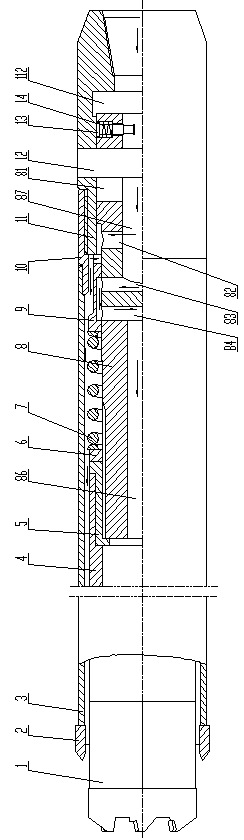

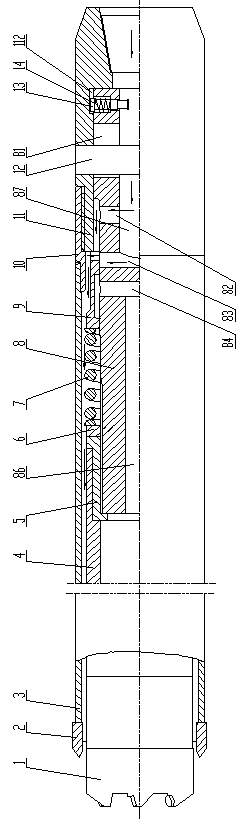

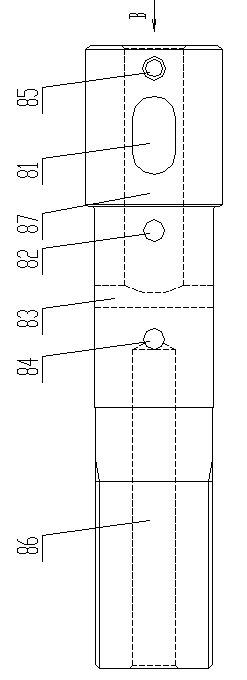

[0022] like Figure 1-9 The new coal sample collection device shown includes an outer protection drill pipe, an inner sampling drill pipe and an air path change mechanism, and the outer protection drill pipe, the inner sampling drill pipe and the air path change mechanism are connected through a drill pipe connecting mechanism.

[0023] The outer protective drill rod includes an outer protective drill pipe 3 and a blade 2 at the front end of the outer protective drill pipe 3 .

[0024] The inner sampling drill rod includes a sampling drill pipe 4 and a sampling drill bit 1 at the front end of the sampling drill pipe 4 .

[0025] The air path direction changing mechanism includes a ventilation mandrel 8 and a pressure regulating nut 6 arranged in sequence outside the ventilation mandrel 8, an airflow reversing pressure spring 7 and an airflow reversing sliding sleeve 9, and the airflow reversing compression spring 7 is located at the pressure regulating Between the nut 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com