Method for determining grinding granularity of ores based on ore properties

A technology for grinding particle size and ore, which is applied in particle size analysis, particle and sedimentation analysis, measuring devices, etc., and can solve problems such as calculation result errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

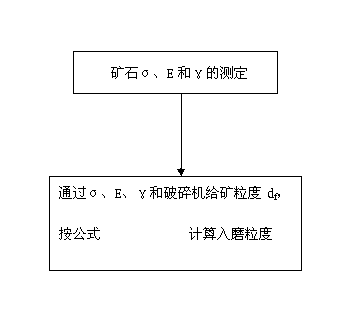

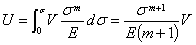

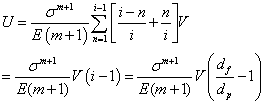

Method used

Image

Examples

Embodiment 1

[0066] The processed ore is quartzite mixed copper ore.

[0067] (1) Determination of ore mechanical properties

[0068] Take 20 representative quartzite mixed copper ores, cut 10 of them into standard test pieces according to the requirements of material mechanics experiment, measure the elastic modulus and ultimate stress of each ore test piece on the material testing machine, and calculate 10 The arithmetic mean of the measurement results, the elastic modulus E is 897600kg / cm 2 , the ultimate stress σ is 680kg / cm 2 Other 10 pieces of ore are processed into the test piece that is suitable for splitting work method to measure specific surface energy, adopt the method for splitting work method to measure specific surface energy to measure the specific surface energy of 10 pieces of ore respectively, calculate 10 measured results The arithmetic mean γ is 2.577 kg / cm;

[0069] (2) Determination of the particle size of the ore entering the mill

[0070] The elastic modulu...

Embodiment 2

[0072] The processed ore is limestone mixed copper ore.

[0073] (1) Determination of ore mechanical properties

[0074] Take 20 representative limestone mixed copper ores, cut 10 of them into standard test pieces according to the requirements of the material mechanics experiment, measure the elastic modulus and ultimate stress of each ore test piece on the material testing machine, and calculate 10 The arithmetic mean of the measurement results, the elastic modulus E is 816000kg / cm 2 , the ultimate stress σ is 510kg / cm 2 ; Another 10 ores are processed into the test piece that the contact angle method is used to measure the specific surface energy, and the method of measuring the specific surface energy by the contact angle method is used to measure the specific surface energy of 10 ores respectively, and calculate the arithmetic of 10 measurement results The average value γ is 2.125kg / cm;

[0075] (2) Determination of the particle size of the ore entering the mill

...

Embodiment 3

[0078] The processed ore is granite copper sulfide ore.

[0079] (1) Determination of ore mechanical properties

[0080] Take 20 representative granite mixed copper ores, cut 10 of them into standard test pieces according to the requirements of material mechanics experiment, measure the elastic modulus and ultimate stress of each ore test piece on the material testing machine, and calculate 10 The arithmetic mean of the measurement results, the elastic modulus E is 1224000kg / cm 2 , the ultimate stress σ is 918kg / cm 2 ; Another 10 ores are processed into the test piece that the contact angle method is used to measure the specific surface energy, and the method of measuring the specific surface energy by the contact angle method is used to measure the specific surface energy of 10 ores respectively, and calculate the arithmetic of 10 measurement results The average value γ is 4.371kg / cm;

[0081] (2) Determination of the particle size of the ore entering the mill

[0082...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com