High-temperature high-pressure multiphase flow corrosion testing device

A high-temperature, high-pressure, corrosion test technology, applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

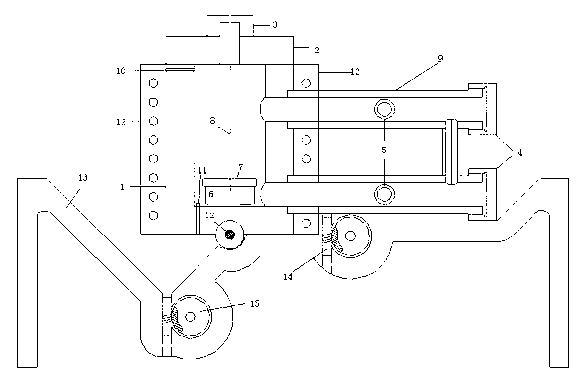

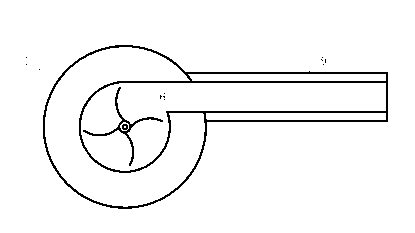

[0024] The invention relates to a high temperature and high pressure multiphase flow corrosion test device. Such as figure 1 As shown, it includes a high-temperature autoclave body 1, a high-temperature autoclave cover 2, a magnetically coupled stirrer 3, a branch pipe 9, a branch pipe sealing device 4, a window 5, blades 6, a flow limiting plate 7, a stirring rod 8, a pressure sensor 10, Temperature sensor 11, heating and insulation device 12. Among them, the lower part of the magnetic coupling stirrer 3 is connected to the stirring rod 8 and the blade 6, and the flow plate 7 is limited above the blade. When there is fluid in the high temperature and high pressure flow corrosion device, the magnetic coupling stirrer 3 drives the lower part to connect the stirring rod 8 and the blade 6 to rotate together. , due to the effect of the restrictor plate 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com