High-temperature and high-pressure flowing device for evaluating corrosion resistance performance of materials

A high-temperature, high-pressure, flow device technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, and analysis materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

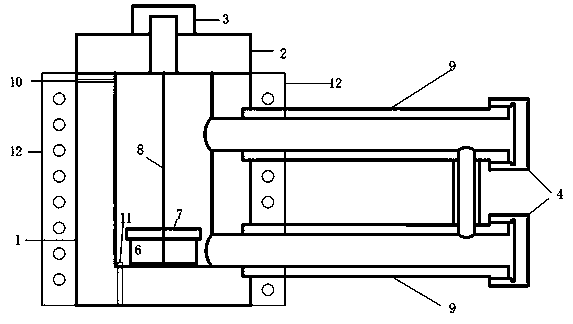

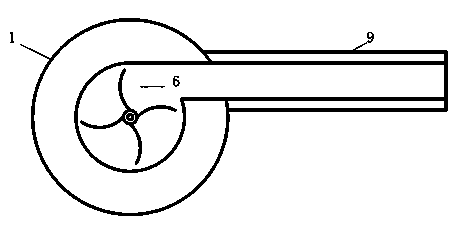

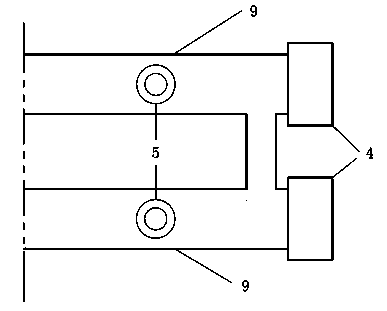

[0025] The invention relates to a high-temperature and high-pressure flow device for evaluating the corrosion resistance performance of materials. Such as figure 1 As shown, it includes a high-temperature autoclave body 1, a high-temperature autoclave cover 2, a magnetically coupled stirrer 3, a branch pipe 9, a branch pipe sealing device 4, a window 5, blades 6, a flow limiting plate 7, a stirring rod 8, a pressure sensor 10, Temperature sensor 11, heating and insulation device 12. Among them, the lower part of the magnetic coupling stirrer 3 is connected to the stirring rod 8 and the blade 6, and the flow plate 7 is limited above the blade. When there is fluid in the high temperature and high pressure flow corrosion device, the magnetic coupling stirrer 3 drives the lower part to connect the stirring rod 8 and the blade 6 to rotate together. , due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com