Method for simulating and predicting transient thermoforming limit of ultra-high strength steel

A forming limit and prediction method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the difficulties of being affected by strain and temperature, transient process condition experimental control and accurate measurement of transient hot forming limit, etc. problem, to achieve the effect of reducing the fluctuation of the forming limit curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

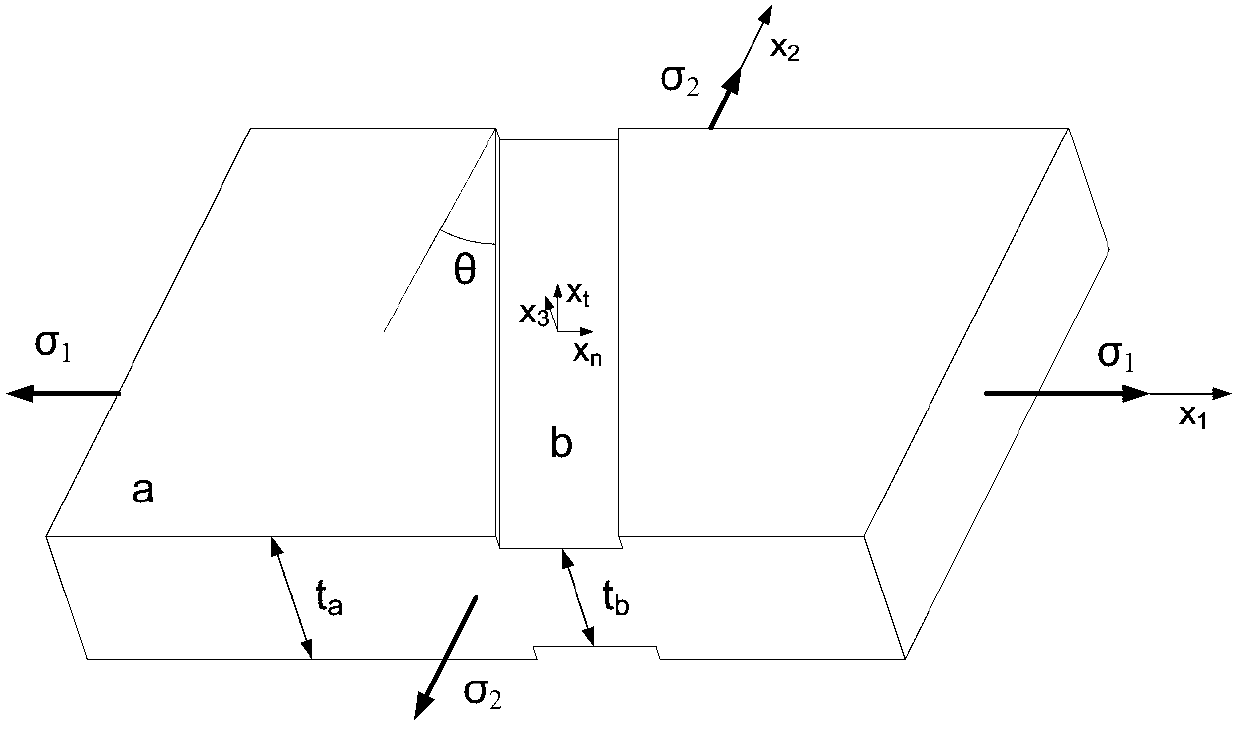

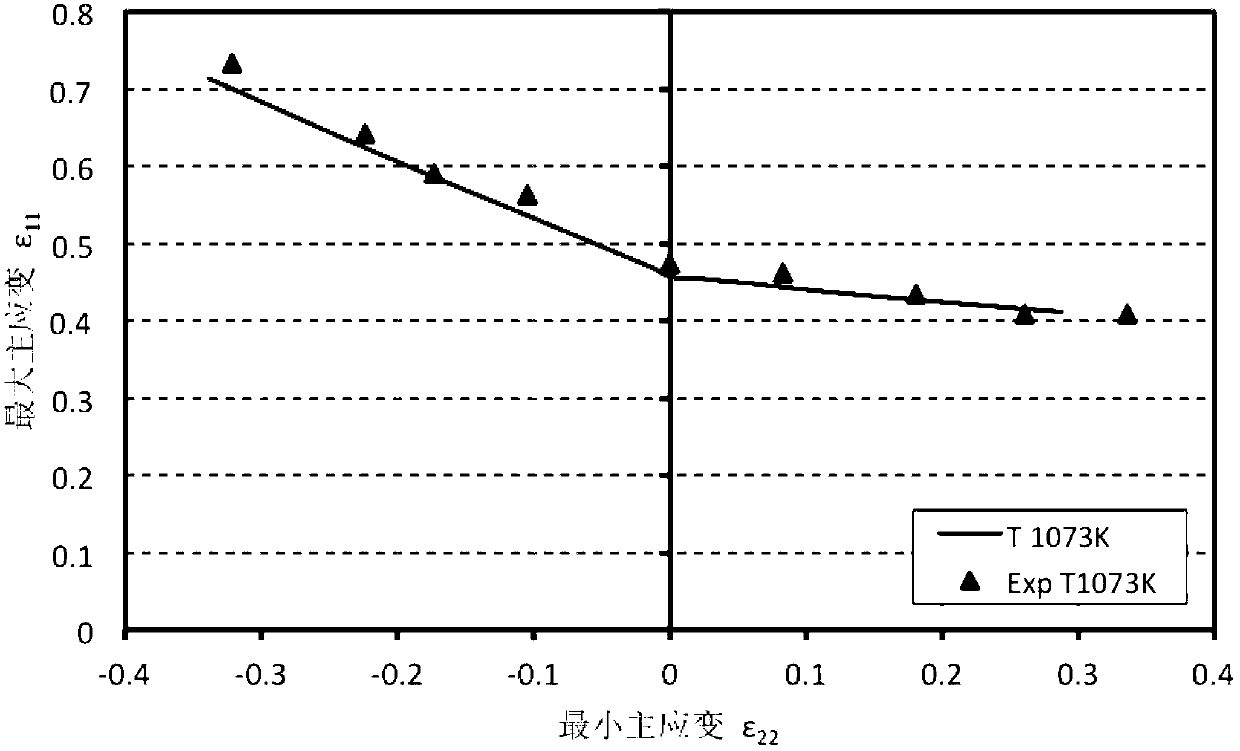

[0028] Based on the M-K concentrated instability theory, combined with the advanced constitutive model, the present invention conducts research on the determination method of the hot forming limit for ultra-high strength steel materials. After the steady state hot forming limit model is determined, the non-equilibrium variable temperature condition is used to simulate the transient state In the forming process, a transient hot forming limit simulation prediction method was established.

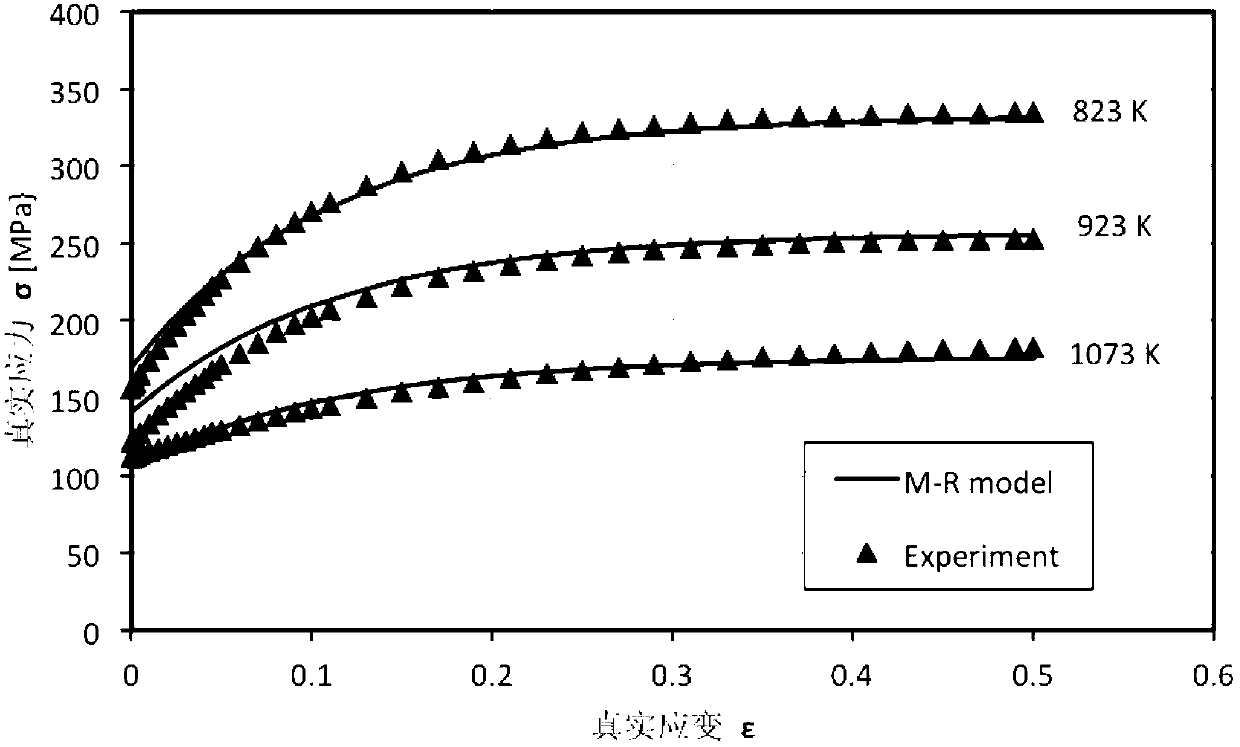

[0029] (1) Establishment of constitutive model of hot-forming sheet metal under steady-state equilibrium conditions

[0030] The choice of material constitutive equation has a great influence on the position and shape of the predicted forming limit curve. Therefore, a reasonable description of the material behavior in the hot forming process is very i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com