Scribing device of multifunctional fully-automatic terminal crimping machine for flat cables

A technology of terminal crimping machine and scribing device, which is applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of low production efficiency, production cost of easy-to-scratch wires, etc., and achieve high efficiency and simple structure Compactness, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

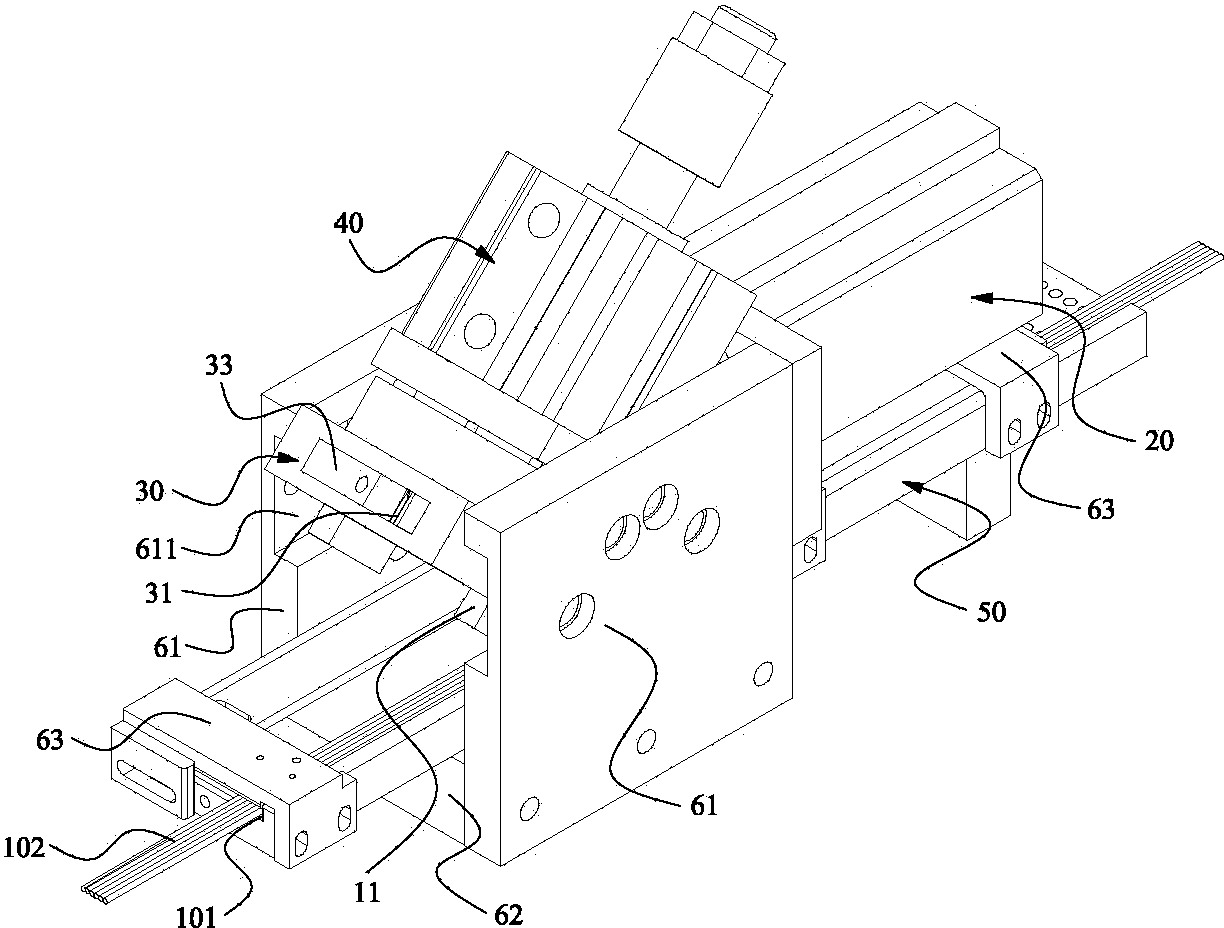

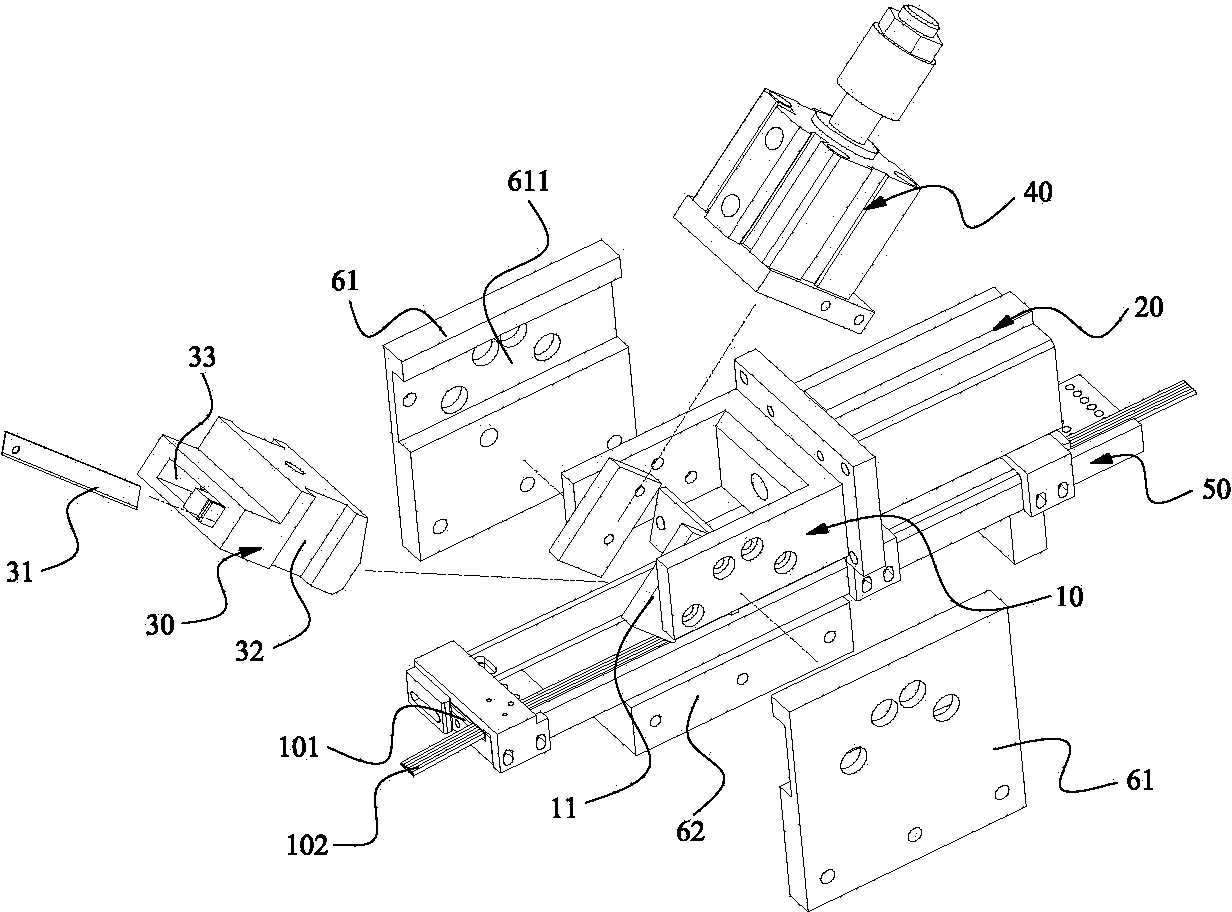

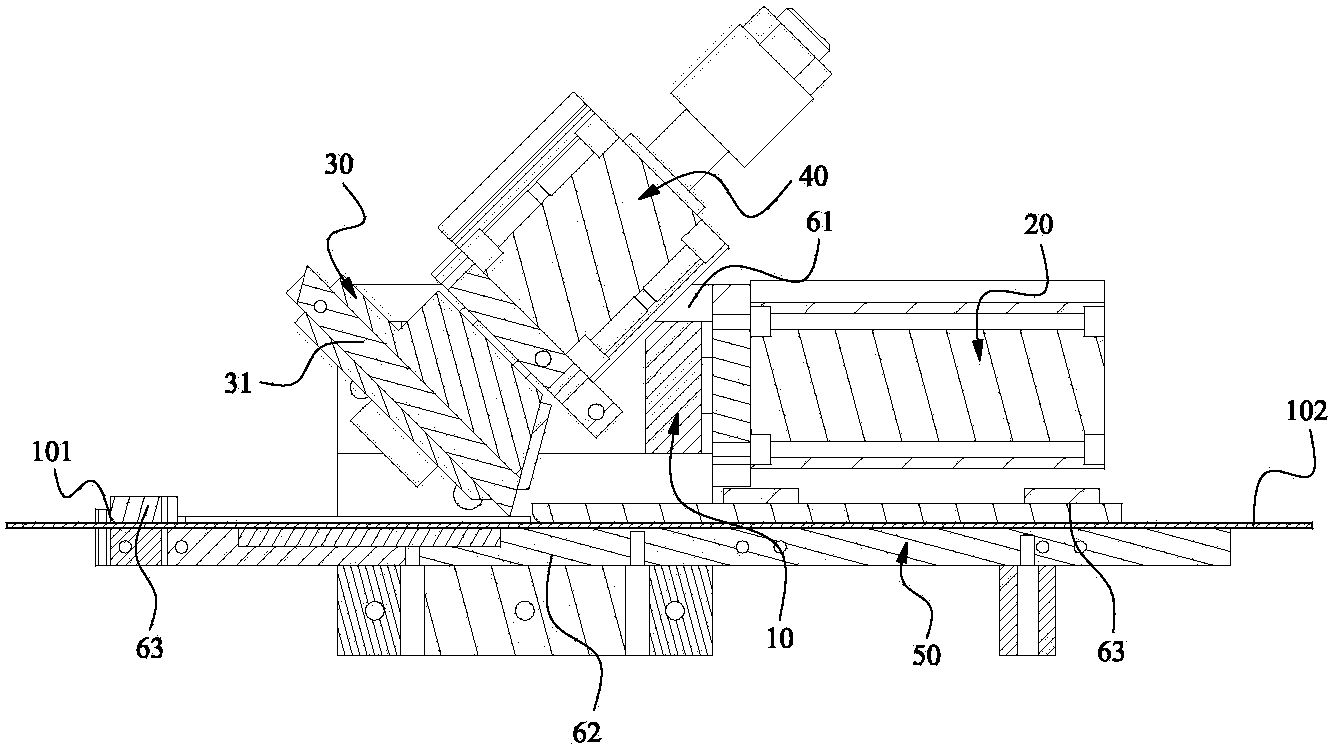

[0033] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is installed on the wire feeding groove 101 of the frame of the multifunctional automatic terminal crimping machine for bonding the cables 102 adjacent to each other The two wires together are separated, including the movable base 10, the translation drive mechanism 20 that drives the movable base 10 to move back and forth along the direction of the wire feeding groove 101, the knife rest 30 that is arranged on the movable base 10, and drives the knife rest 30 up and down. The moving push-down drive mechanism 40 .

[0034] The movable base 10 is a U-shaped frame body with an open front end, and a guide block 11 is fixedly installed on both inner sides of the front end opening of the U-shaped frame body, and the guide block 11 extends obliquely forward and downward.

[0035] The tool holder 30 is provided with a plurality of blades ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com