Motor inner stator with adjustable outer diameter and manufacture method of motor inner stator

An adjustable, internal stator technology, applied in the manufacture of stator/rotor body, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve problems such as interference and insufficient slot space, and achieve easy assembly and reduce The effect of production cost and convenient winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Such as Figure 13 , Figure 14 As shown, the inner stator of the motor with adjustable outer diameter includes stator core III, winding IV and bracket V.

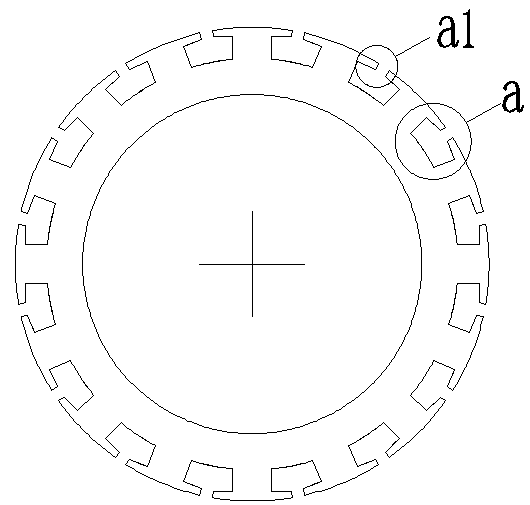

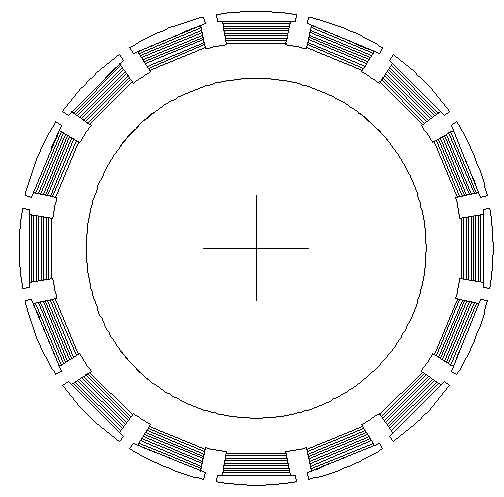

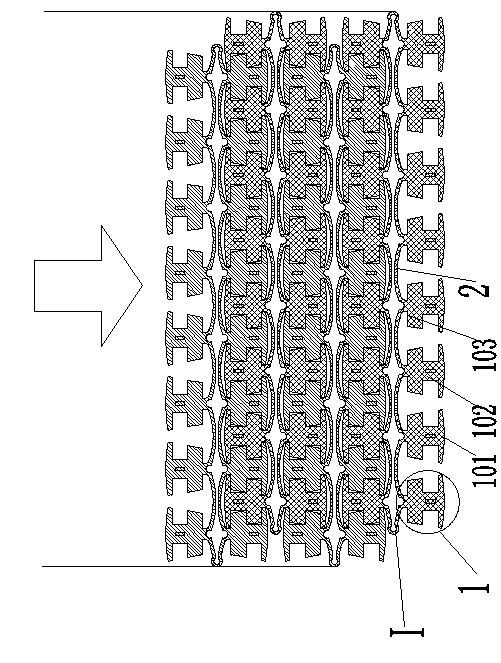

[0048] Such as Figure 3-Figure 7 As shown, the stator core III is formed by overlapping and deforming a plurality of ring-shaped integrated stator core punches I. The initial shape of the stator core punch I is a flat ring, and finally unfolded into a ring shape. Each stator core punching piece I has a plurality of tooth pieces 1 and connecting body 2, each tooth piece 1 includes tooth crown 101, tooth body 102 and tooth root 103, connecting body 2 is connected with the bottom of the tooth root 103 of the adjacent tooth piece .

[0049] Tooth pieces 1 of multiple stator core punching pieces I are superimposed to form a unit tooth block 3 of stator core III. Each unit tooth block 3 has a tooth crown 301, a tooth body 302 and a tooth root 303, and the connecting body 2 is correspondingly superimposed. The connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com