Permanent magnet motor rotor with excitation circuit variable reluctance and leakage flux path function

A technology of excitation circuit and permanent magnet motor, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of permanent magnet motor weak field speed regulation and other problems, and achieve the effect of large output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

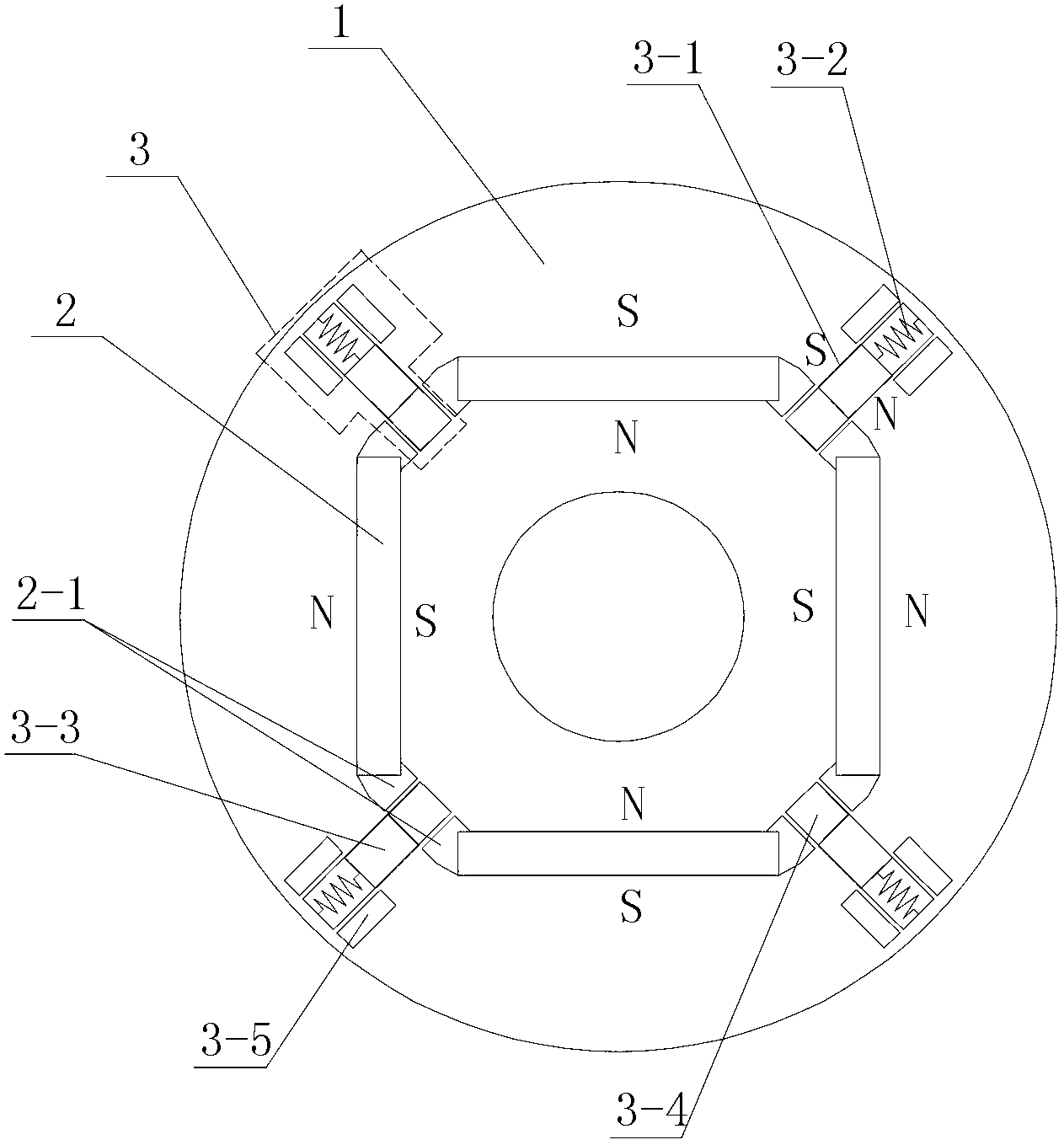

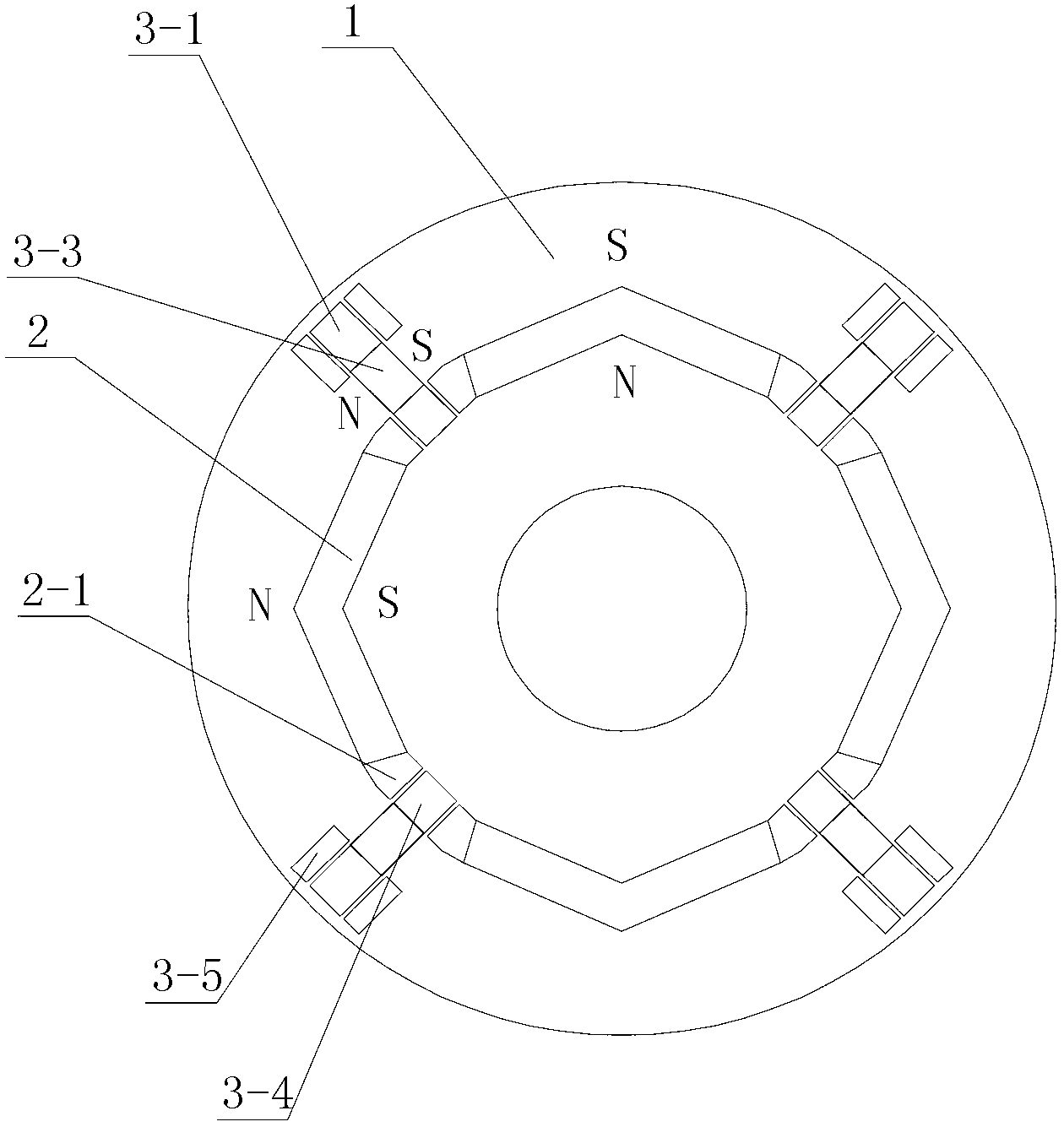

[0025] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe this embodiment, the permanent magnet motor rotor with the function of excitation circuit variable reluctance and flux leakage path described in this embodiment, it includes a rotor core 1, it also includes 2n main permanent magnets 2 and 2n field weakening units 3, n is a positive integer,

[0026] There are 2n through slots along the axial direction of the rotor core 1, and the 2n through slots are evenly distributed along the circumferential direction of the rotor core 1, and a main permanent magnet 2 with a matching shape is embedded in each through slot,

[0027] A field-weakening unit 3 is arranged between every two adjacent main permanent magnets 2 along the circumferential direction on the rotor core 1, and a magnetic isolation slot is provided between the two ends of the main permanent magnet 2 along the circumferential direction and the adjacent field-weakening units 3 ...

specific Embodiment approach 2

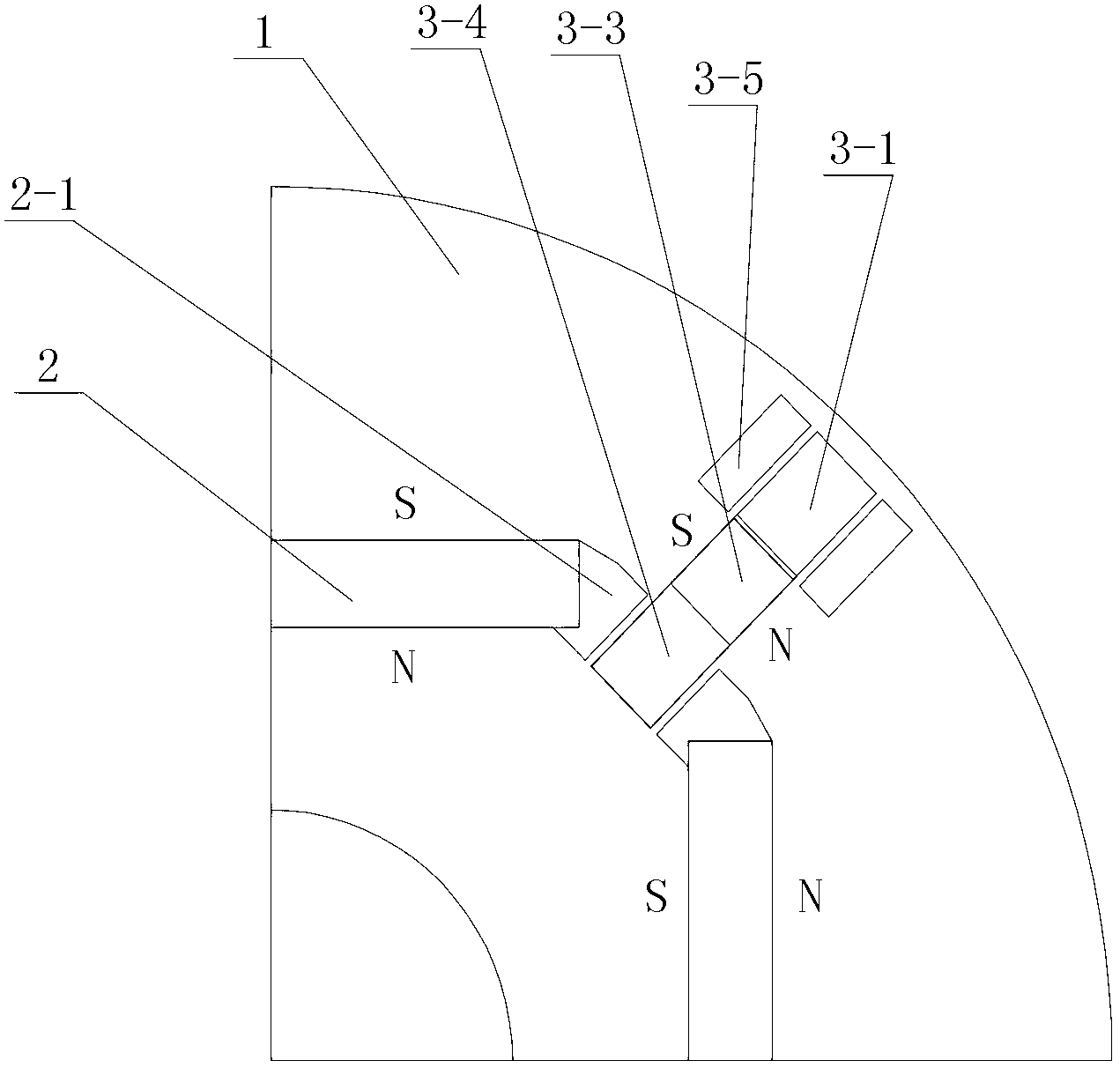

[0030] Specific implementation mode two: the following combination Figure 1 to Figure 4 Describe this embodiment. This embodiment is a further description of Embodiment 1. Each field weakening unit 3 includes a slide rail groove 3-1, a spring 3-2, an auxiliary permanent magnet 3-3, a magnetic block 3-4 and Two non-magnetic slots,

[0031] The slide rail groove 3-1 is arranged radially between the two main permanent magnets 2 on the rotor core 1, and the spring 3-2, the auxiliary permanent magnet 3-3 and the magnetic guide block 3-4 are arranged radially from outside to inside The cloth is arranged in the slide rail groove 3-1, the fixed end of the spring 3-2 is fixedly connected with the groove bottom of the slide rail groove 3-1, and the free end of the spring 3-2 is fixedly connected with one end of the auxiliary permanent magnet 3-3, The other end of the auxiliary permanent magnet 3-3 is fixedly connected to the magnetic permeable block 3-4; the radial length of the magne...

specific Embodiment approach 3

[0039] Specific implementation mode three: the following combination Figure 1 to Figure 4 Describe this embodiment, this embodiment is a further description of Embodiment 2, the field weakening unit 3 also includes two non-magnetic permeable blocks 3-5, each non-magnetic permeable block 3-5 is embedded in a non-magnetic permeable slot .

[0040] The non-magnetic conductive block 3-5 can be a non-magnetic conductive metal body, and the shape of the non-magnetic conductive block 3-5 can be set as rectangle, square, triangle or trapezoid as required.

[0041] When the motor system where the rotor core 1 is located is running at or below the base speed, the magnetic block 3-4 and the auxiliary permanent magnet 3-3 are stationary and do not move, and the highest point of the radial height of the auxiliary permanent magnet 3-3 is lower than the non- The height of the lowest radial point of the magnetic block 3-5. At this time, the auxiliary permanent magnet 3-3 in the slide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com