Board surface cleaning machine

A technology of cleaning machine and board surface, applied in the direction of cleaning/polishing of conductive patterns, secondary treatment of printed circuits, etc., can solve the problem of low production efficiency, improve the degree of cleaning and dust removal, ensure manufacturing quality, and improve product qualification rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

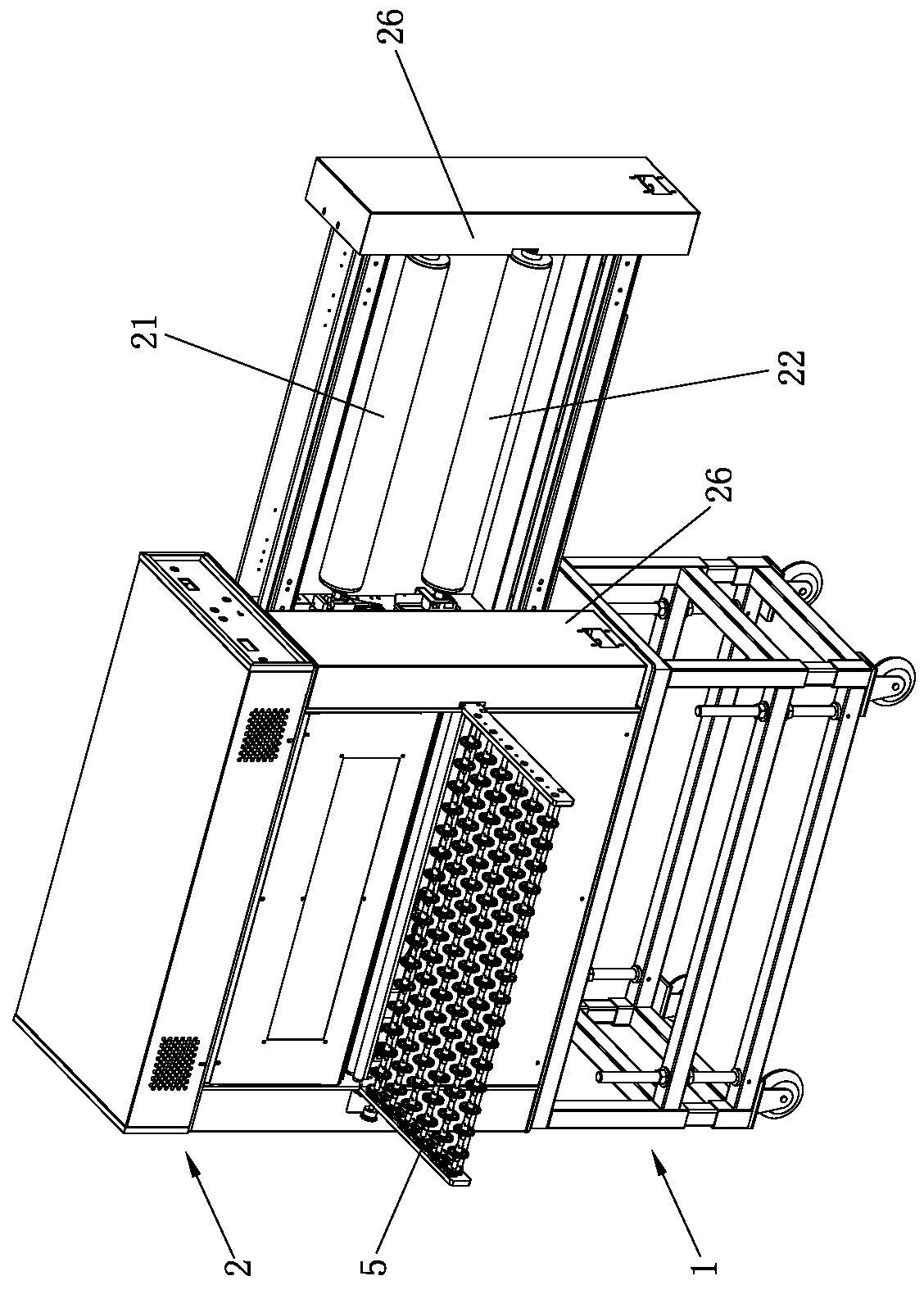

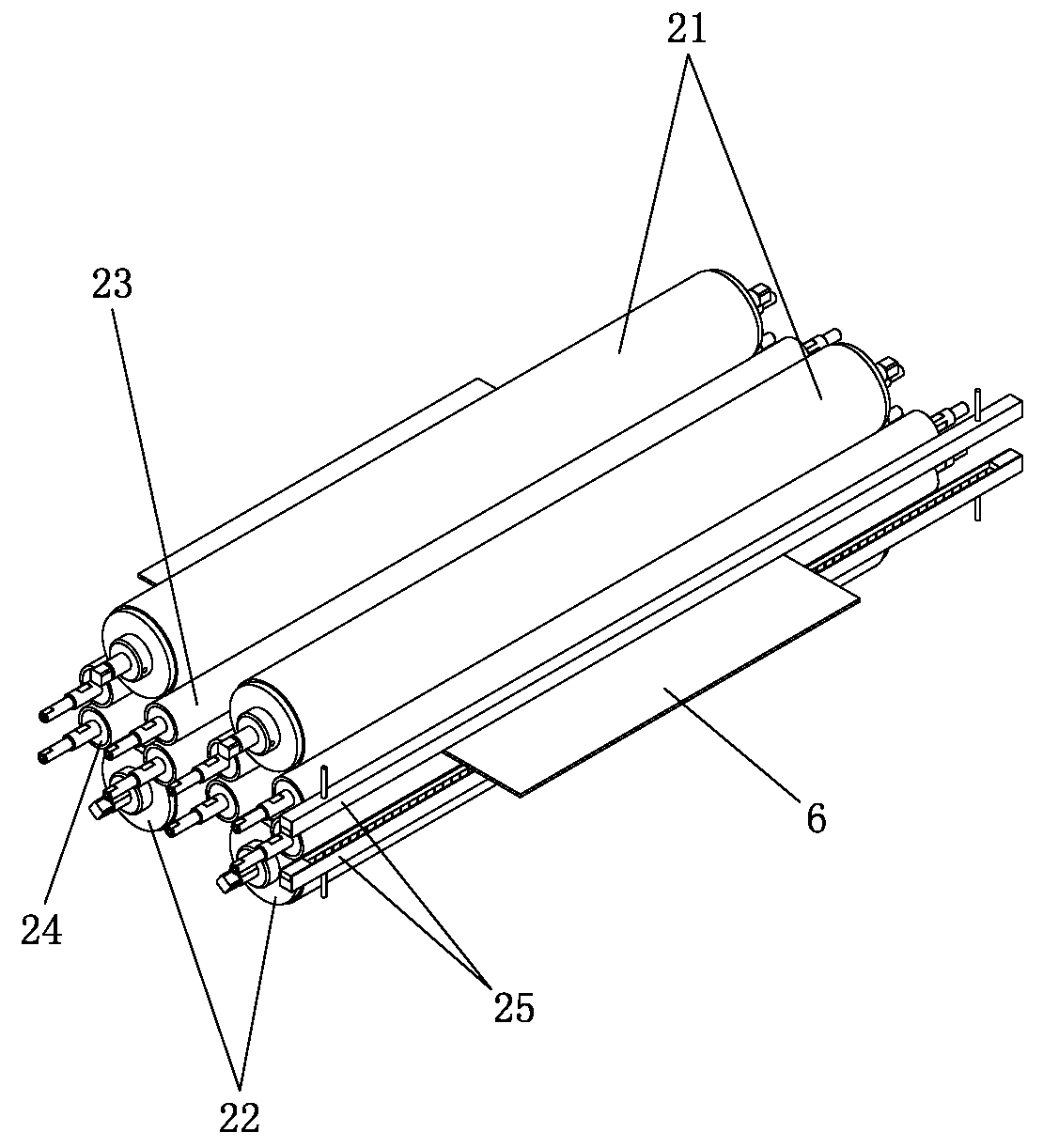

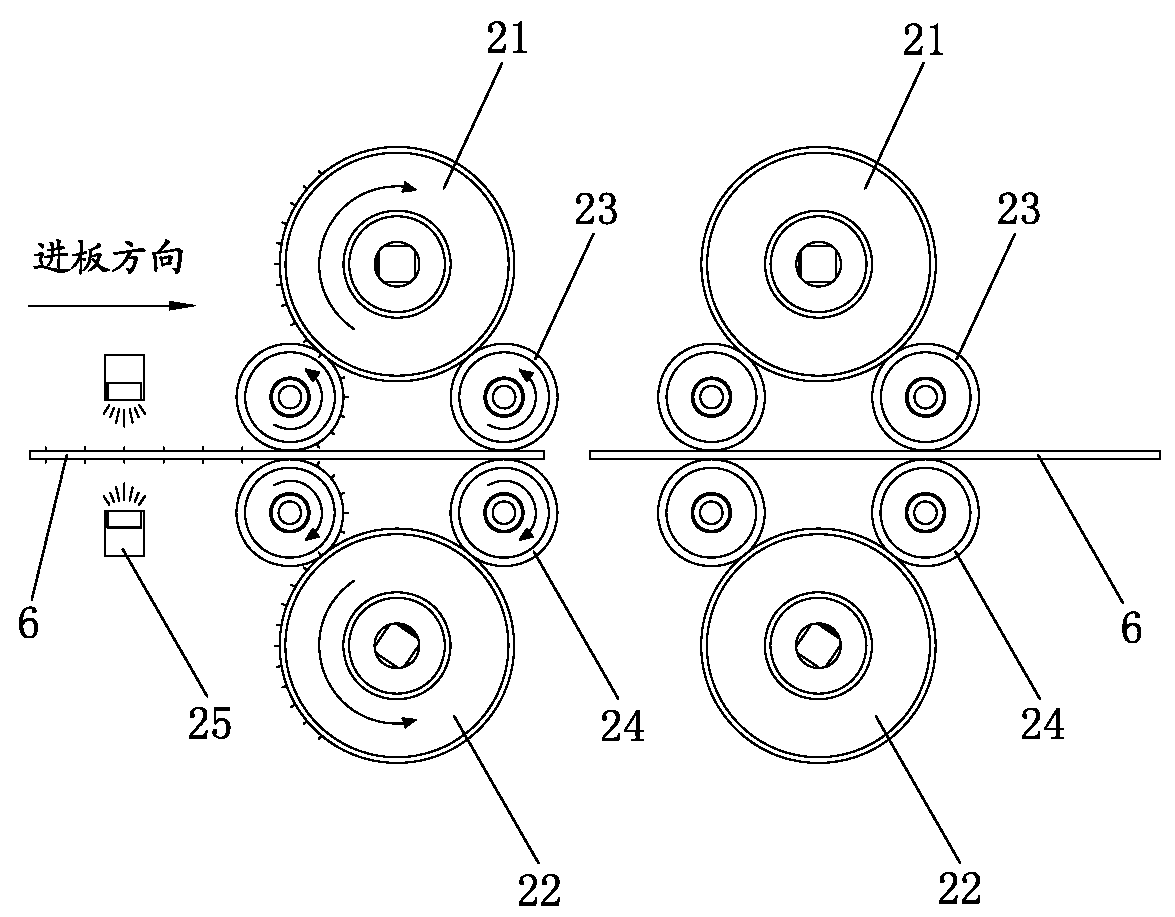

[0026] Please refer to Figures 1 to 3 , The present invention provides a board surface cleaning machine, comprising a base 1 and a dust removal mechanism 2 installed on the base 1. The dust removal mechanism 2 includes two stages of dust removal devices arranged in sequence, and the two stages of dust removal devices are arranged front and rear, wherein the dust removal device The device includes an upper dust sticking roller 21, a lower dust sticking roller 22, and two groups of cleaning rollers before and after. Each group of cleaning rollers is provided with an upper cleaning roller 23 and a lower cleaning roller 24. In order to pass through the gap of the printed circuit board 6 that needs to be cleaned and dedusted, when the printed circuit board 6 that needs to be cleaned and dedusted passes through the gap between the upper cleaning roller 23 and the lower clea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap