Oxazolidone ring contaning adducts

A technology containing oxazolidone ring and oxazolidinone ring, which is used in epoxy resin coatings, powder coatings, organic chemistry and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

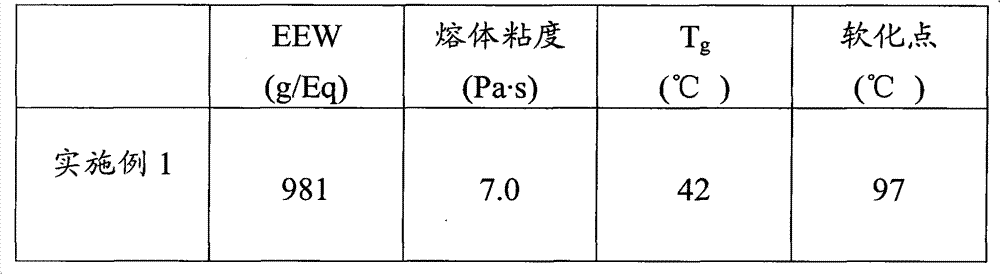

[0053] Embodiment 1 (adduct containing oxazolidinone ring)

[0054] 390 grams (g) D.E.R. TM 736 was added to the flask and the contents of the flask were heated to 130°C. 2 g of DBU was added to the flask over a period of approximately 60 seconds and the contents of the flask were maintained at 145°C. 210 g of MDI was added to the flask over 60 min and the temperature of the contents of the flask was maintained at a temperature of 160°C to 170°C. The contents of the flask were kept at a temperature of 165 °C for 15 min. A sample was obtained and the EEW was determined to be about 1450. 280g D.E.R.TM 330 was added to the flask and the contents of the flask were maintained at a temperature of 140°C to 150°C. 120 g of MDI was added to the flask over 60 min and the temperature of the contents of the flask was maintained at a temperature of 170°C to 175°C. The contents of the flask were kept at a temperature of 165 °C for 15 min to generate Example 1. Epoxy equivalent weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com