Feeding bottle

A feeding bottle and bottleneck technology, which is applied to feeding bottles and other directions, can solve the problems of increasing liquid outflow resistance and baby sucking hard, and achieve the effect of reducing contact time and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065]In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

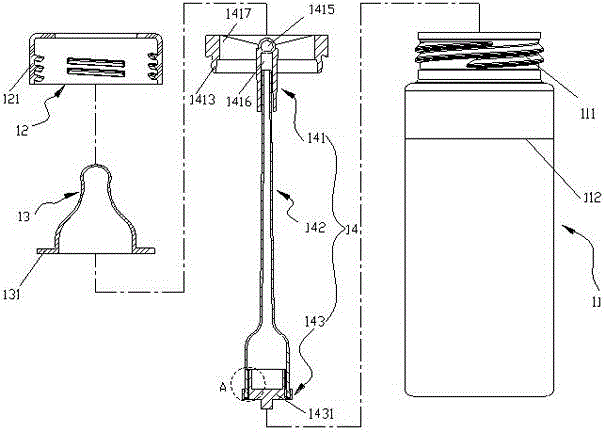

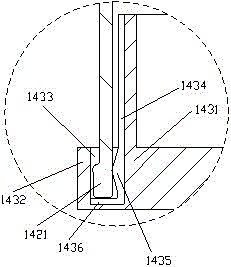

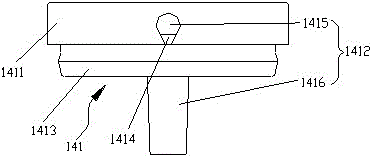

[0066] Figure 1 to Figure 6 Shown is a feeding bottle according to a first disclosed embodiment of the present invention.

[0067] Such as figure 1 Shown, feeding bottle of the present invention comprises:

[0068] Bottle body 11, the bottle body 11 has an open bottleneck 111 and threads around the outside of the open bottleneck 111, the bottle body 11 is provided with an upper liquid level line 112;

[0069] The top cover 12, the top cover 12 has a threaded side portion 121, the threaded side portion 121 can fix the top cover 12 and the bottle body 11, or loosen the top cover 12 and the bottle body 11 ;

[0070] A pacifier 13, the pacifier 13 has a radially extending fixing portion 131, and the fixing portion 131 is located between the top cover 12 and the bottle neck 111;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com