Pressurization rotating drum filtering machine

A filter and drum technology, applied in the direction of filtration separation, mobile filter element filter, separation method, etc., can solve the problems of poor operating environment, large footprint, and difficult filtration of plate and frame filter presses, and achieve dehydration effect Good, large processing capacity, fast solid-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described;

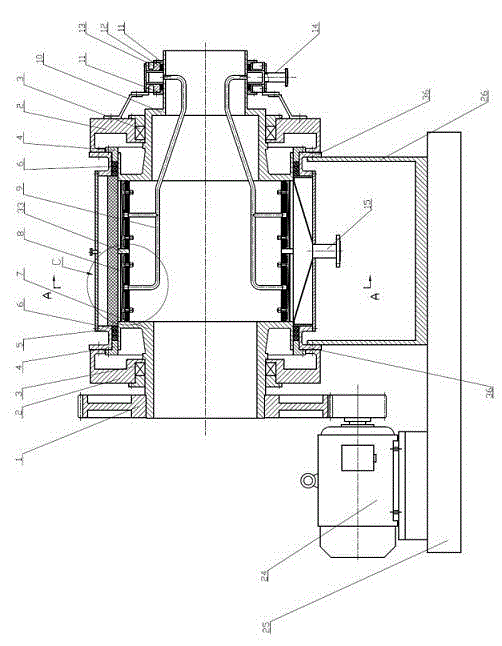

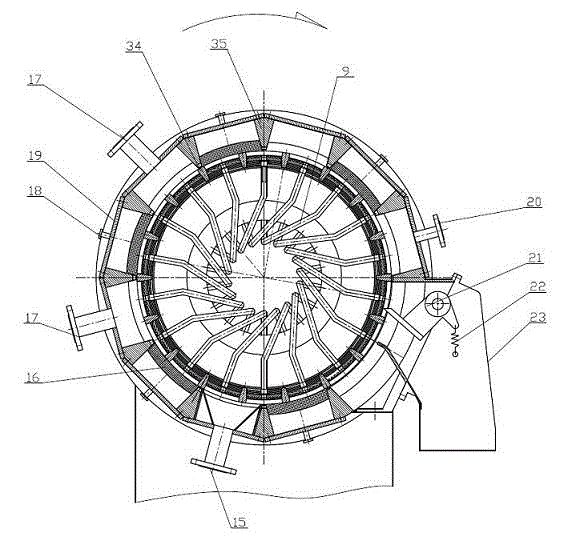

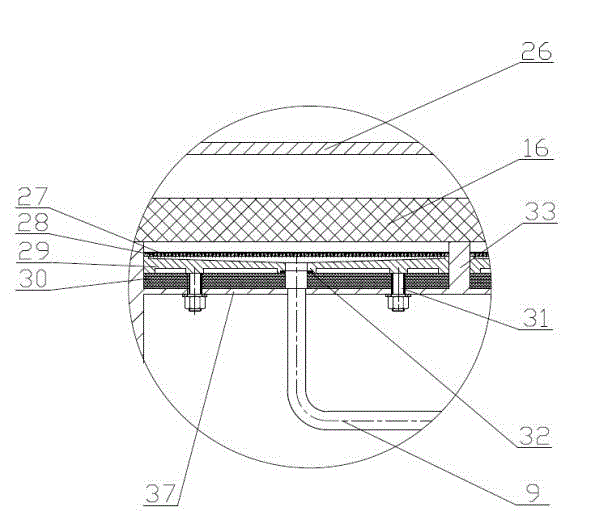

[0012] A pressurized drum filter, comprising a base 25, a casing 5, a frame 26 and a bearing seat 2, characterized in that: the casing 5 is mounted on the base 25 through the frame 26, and a motor 24 is also arranged above the base 25; The casing 5 is composed of connecting flanges 36 at both ends and a partition 35 in the middle. The partitions 35 are distributed in the circumferential direction. The partition 35 and the connecting flanges 36 at both ends form a frame chamber, and sealing pressure plates are also arranged at intervals in the frame chamber. 16. A sealing plate 19 is provided on the outside of the frame chamber. The sealing plate 16 corresponding to the sealing plate 16 outside the frame chamber is provided with an air pipe joint 18. The sealing plate 19 corresponding to the outside of the frame chamber without the sealing pressure plate 16 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com