Beam of steel plate straightener

A technology of straightening machine and crossbeam, which is applied in the field of steel strip straightening machine, can solve problems such as difficult structural design, limited adjustment amount, complex motion mechanism, etc., and achieve the effect of eliminating the bouncing phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

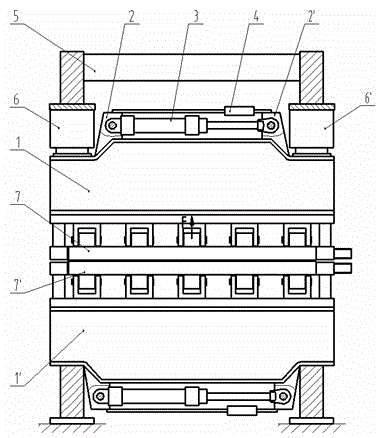

[0010] Such as figure 2 As shown, the steel plate straightening machine includes a frame 5, left and right pressing devices 6, 6', upper and lower beams 1, 1', and upper and lower roller systems 7, 7'.

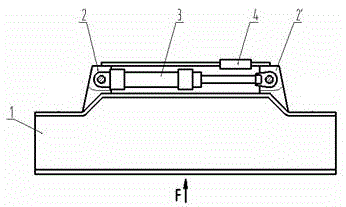

[0011] Taking the upper beam 1 of the steel plate straightening machine as an example, during the production of the steel plate straightening machine, the straightening force F The upper roller system 7 acts on the lower bearing surface of the upper beam 1, forcing the upper beam to produce upward convex negative bending deflection deformation f At this time, the sensor 4 installed on the upper beam 1 detects the deformation signal of the upper beam 1 and transmits it to the tension PID controller to control the hydraulic cylinder 3 to apply a tension on the left and right supports 2, 2' N , forcing the beam to produce positive bending deflection deformation δ . Deformation due to positive bending deflection δ The deformation direction of the beam and the negative bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com