Construction method of anti-bending reinforced floor structure

A construction method and technology for reinforcing plates, which are applied in building construction, building maintenance, construction, etc., can solve problems such as poor reinforcement effect, difficult construction, and inconvenient maintenance, and achieve low construction difficulty, reduced material costs, and reduced manpower. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

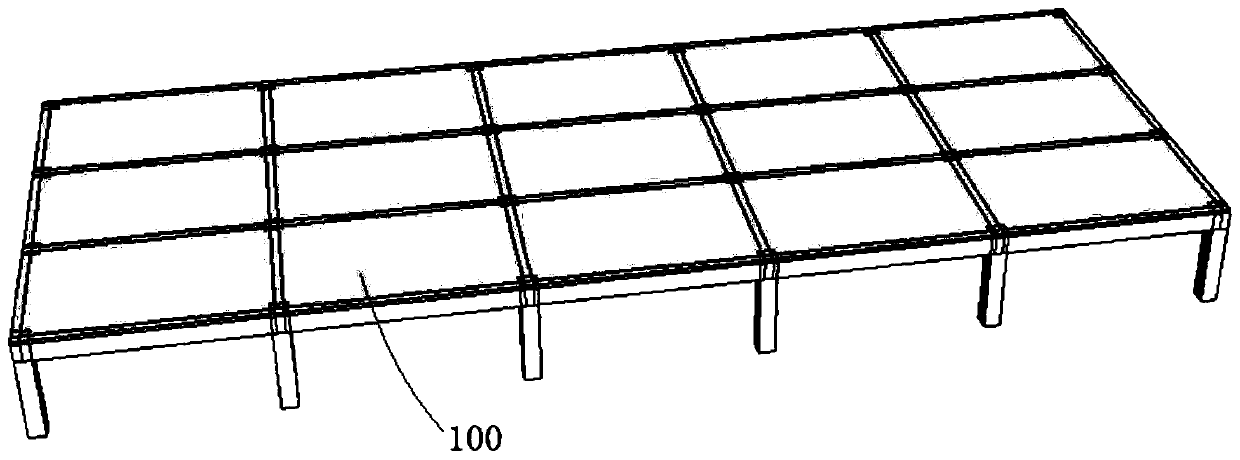

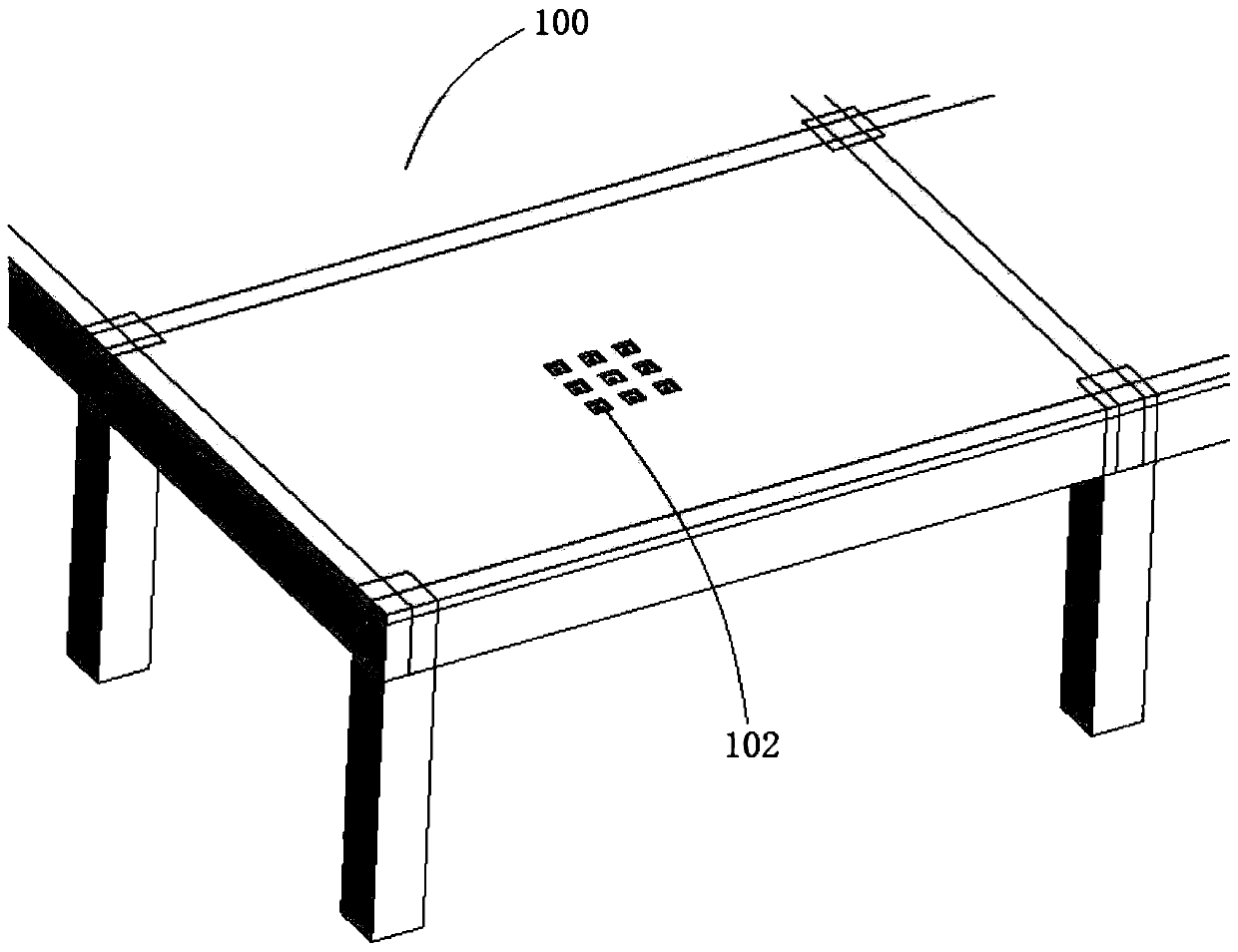

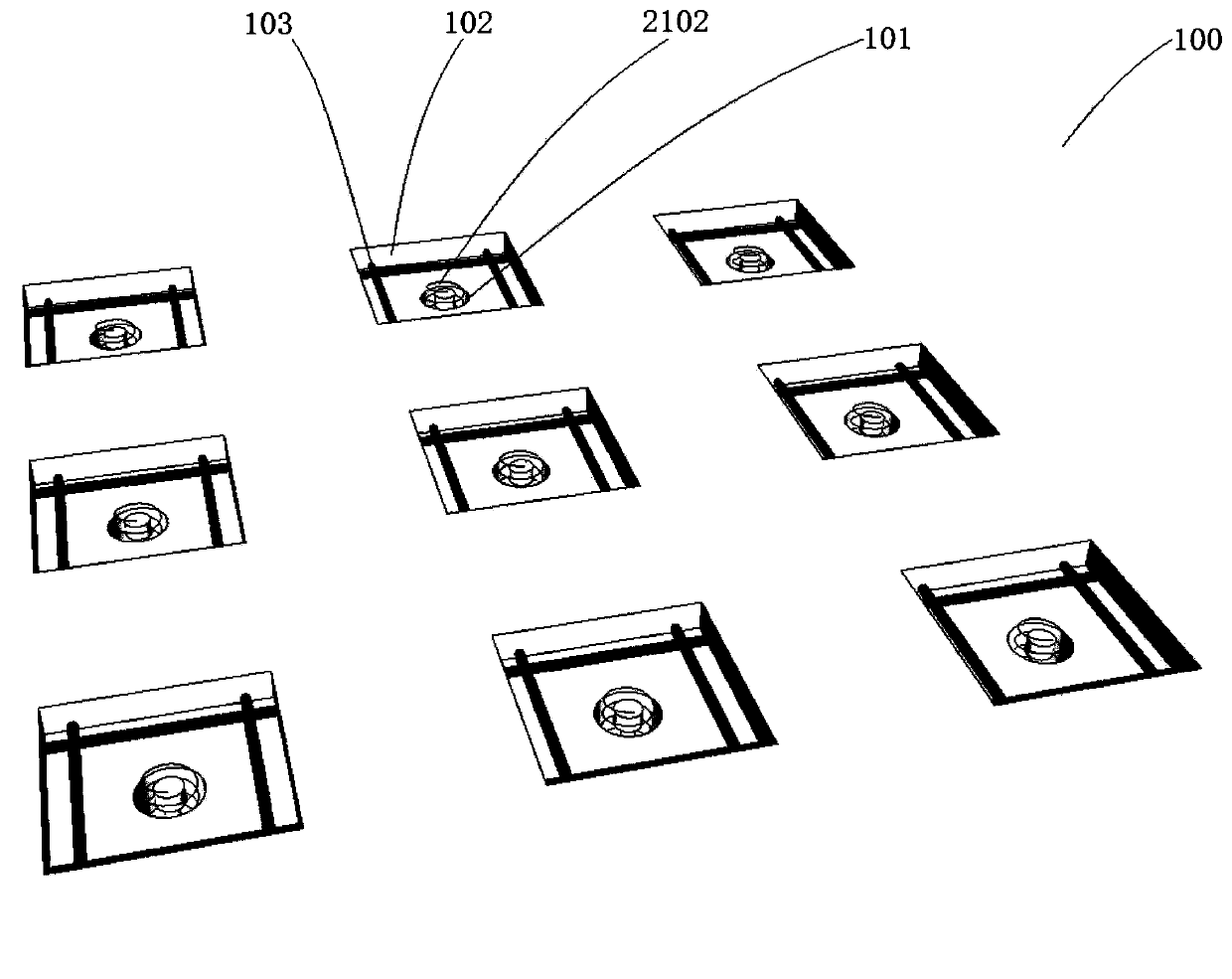

[0050] In Embodiment 1, the fixing hole is a fixing through hole 101 penetrating through the two sides of the floor main body 100, and the shear connector 210 is inserted into the fixing through hole 101 from below, so that the reinforcing body 200 fixed at figure 1 and figure 2 The lower surface of the floor body 100 is shown.

[0051] In Example 1, refer to Figure 4 , the reinforcing body 200 includes a plurality of reinforcing plates 201 , and the plurality of reinforcing plates 201 are arranged vertically and horizontally in the middle of the lower surface of the floor main body 100 . Reinforcement plates 201 arranged vertically and horizontally form a mesh reinforcement surface, which can bear most of the weight and load of the floor main body 100 from below, thus effectively strengthening the floor; meanwhile, the middle part of the floor main body 100 bears a larger load than the edge parts More concentrated, the net-shaped reinforcing plate 201 can directly support ...

Embodiment 2

[0066] Such as Figure 6 In the second embodiment shown, the fixing hole is a fixing counterbore 101' provided on the installation side of the floor main body 100', and the shear connector 210' is inserted into the fixing counterbore 101', so that The reinforcing body 200' is fixed on the installation side.

[0067] It should be noted that the installation side of the second embodiment can be the upper surface of the middle span 110' of the floor main body 100', or the outer surface of the side span 120' of the floor main body 100'.

[0068] For ease of understanding, the reinforcing body 200 ′, the shear connector 210 ′ and the bonding body 300 ′ used in the second embodiment are the same as those in the first embodiment. Next, taking the construction on the upper surface of the mid-span 110' of the floor main body 100' as an example, the specific construction method is described as follows:

[0069] (1) The concrete on the upper surface of the floor main body 100' is chise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com