Automatic material feeding and discharging structure of punching machine for punching cover plate of iron wine box

A technology of automatic feeding and wine box, applied in the direction of pushing out equipment, feeding device, positioning device, etc., can solve the problems of high labor intensity, low work efficiency, and many wastes, etc., to reduce labor intensity and reduce labor intensity. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

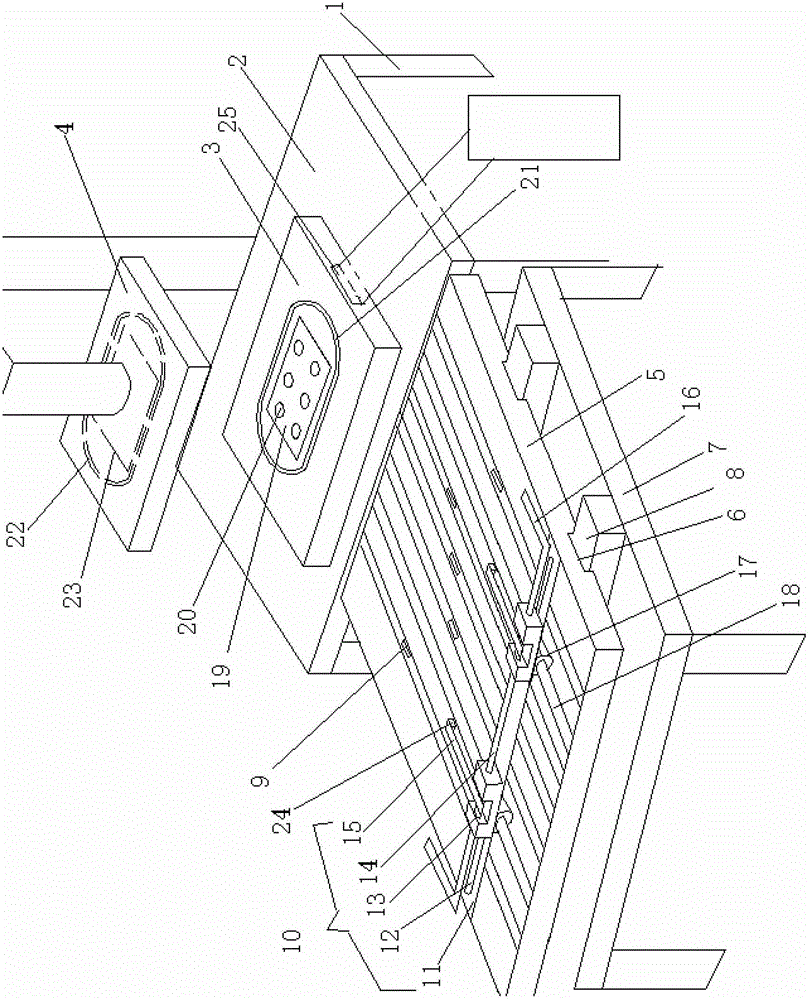

[0015] Referring to the accompanying drawings, an automatic feeding and discharging structure of a punch press for stamping iron wine box cover plates includes a frame 1, a workbench 2 is set on the frame 1, a mold base 3 is arranged on the workbench 2, and the workbench 2. A punch 4 matching with the mold base is erected on the top, and a feeding frame 5 matching with the working table is installed on the front end of the workbench 2. The feeding frame 5 is installed on the guide rail 8 on the bracket 7 through the guide groove 6. The feeding frame 5 The movement is driven by an air cylinder. Grooves are distributed on the feeding frame 5, and support pads 9 are placed in the grooves. The flipping clamping frame 10 is mounted on the feeding frame 5. The flipping clamping frame 10 includes a fixed plate 11, and a fixed plate 11 An adjustment groove 12 is arranged on the top, and a fixed seat 13 is installed on the fixed plate 11 through the adjusted groove 12. A rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com