Auxiliary tool for assembling bolts

A technology of auxiliary tools and bolts, which is applied in the direction of manufacturing tools, hand-held tools, etc., and can solve problems such as difficult installation or disassembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

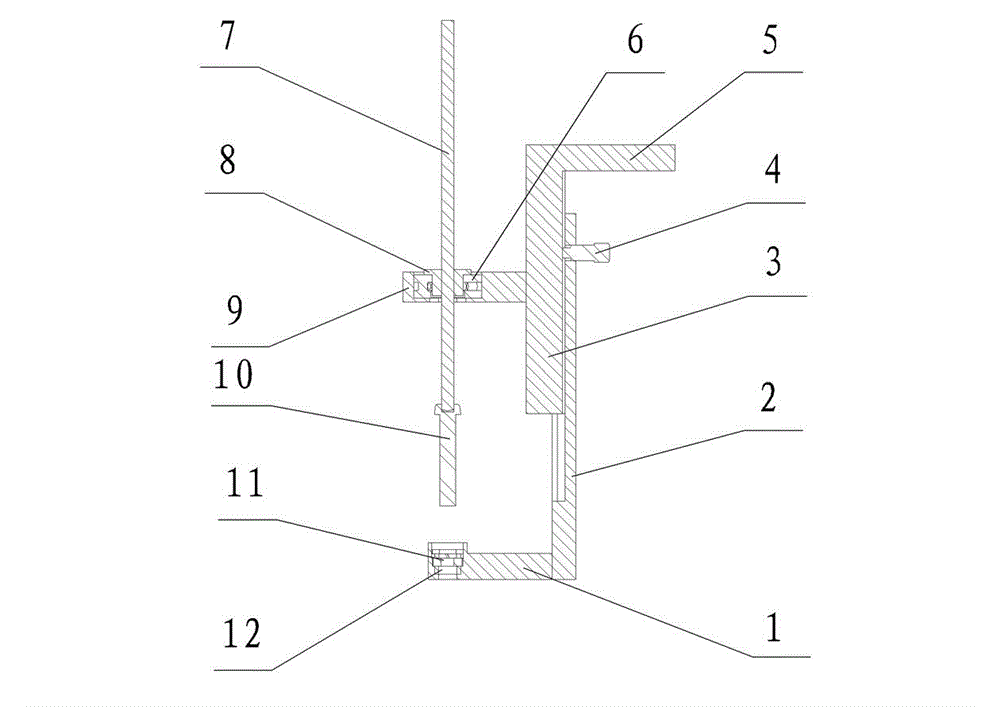

[0011] The embodiment of auxiliary tool for bolt assembly of the present invention: as figure 1 As shown, it includes a bracket, a slider 3, and a guide rod 7. The bracket is composed of a column 2 and a base plate 1 fixed on the lower end of the column 2 and extending in the horizontal direction. 11 adapted to the positioning hole, the positioning of the nut 11 can be realized by placing the nut 11 in the positioning hole. For those who need to assemble the gasket at the same time, the nut and the gasket can also be put into the positioning hole together. The guide rod 7 is Hexagonal rod, and it just fits with the inner hexagonal hole of the head of the bolt 10, and the guide rod 7 is also magnetic, and the bolt 10 can be placed on one end of the guide rod 7 to realize the positioning and adsorption of the bolt 10. The column 2 is provided with a slide rail extending in the up and down direction, and the slide block 3 is slidably assembled on the column 2 through the slideway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com