Annealing method of gas furnace

A technology for gas generator and smoldering, which is applied in the manufacture of combustible gas and petroleum industry, etc., can solve the problems of overheating of the material layer, prolong the simmering time, and deteriorate the furnace condition, so as to slow down the gasification speed and prevent the The effect of layering and even air distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

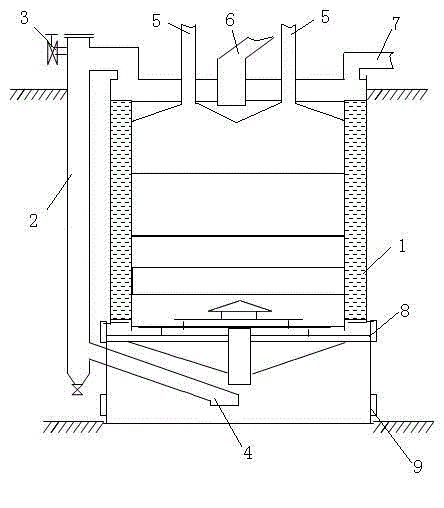

[0017] On the third floor where the fireman's duty room is located, above the air saturation pipe of the producer, a DN200 control butterfly valve is installed as an air volume regulating valve during annealing. Compared with the 350*500mm lower ash door on the second floor, the advantages are obvious: 1 . The air volume can be adjusted to the minimum to slow down the gasification speed; 2. Through the saturated pipe, the air can be evenly distributed to ensure the stability of the furnace condition; 3. The inside of the annealing valve is directly facing the water jacket to produce a mixed layer of steam and air. Automatically realize the synchronous adjustment of the temperature and steam volume in the furnace, achieve the effect of a gentle braising furnace, and effectively prevent the occurrence of material layer caking during the braising furnace. 4. The position of the control butterfly valve is appropriate and the operation is convenient. 5. Under certain temperature co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com