Pallet and substrate processing equipment with pallet

A technology of processing equipment and trays, which is applied in the field of microelectronics, can solve problems such as uneven heating of trays, and achieve the effect of improving substrate processing efficiency and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

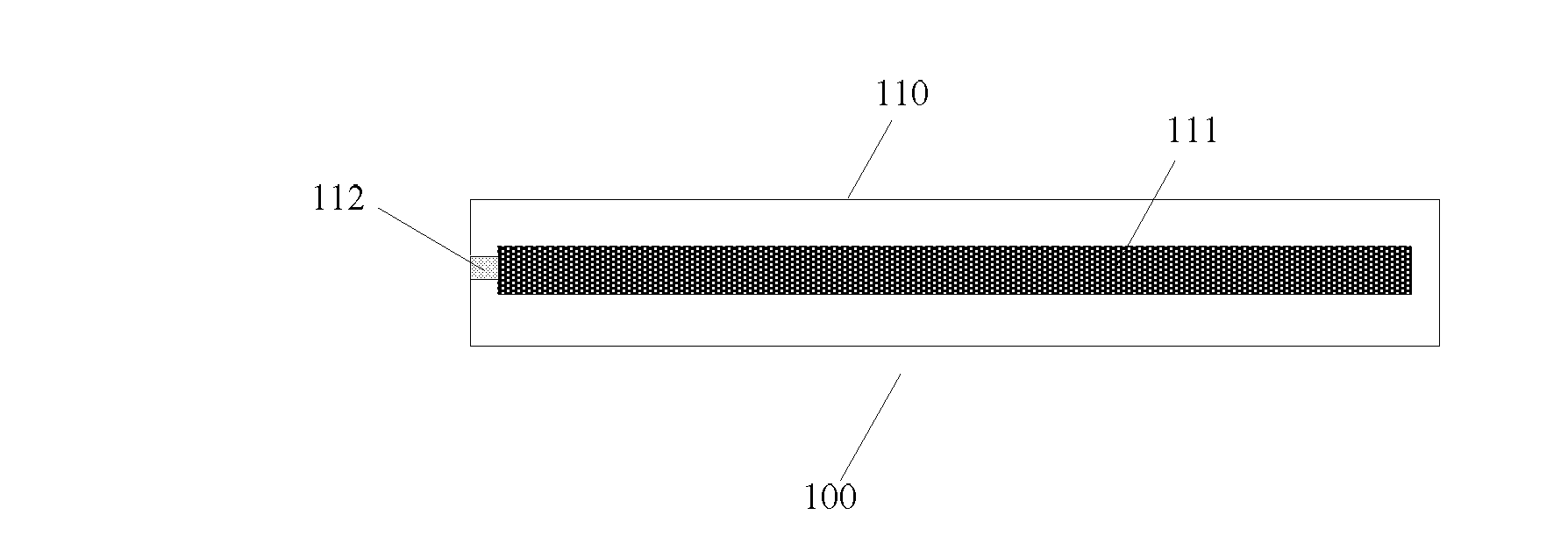

[0037] Such as figure 1 Shown is a longitudinal cross-sectional view of a tray according to an embodiment of the present invention. The tray 100 according to the embodiment of the present invention includes a tray body 110 having a hollow structure 111 inside the tray body 110. Among them, the hollow structure 111 is filled with a material with a lower melting point than the tray body 110, preferably a metal.

[0038] According to the tray 100 of the embodiment of the present invention, the tray body 110 is filled with a material whose melting point is lower than that of the tray body 110. During the induction heating process, when the temperature of the tray body 110 rises to the melting point of the filling material, the filling material melts into a liquid state. , The liquid filling material itself forms thermal convection to make its temperature uniform, and the liquid filling material forms heat exchange with the tray body, thereby reducing the temperature difference on the...

Embodiment 2

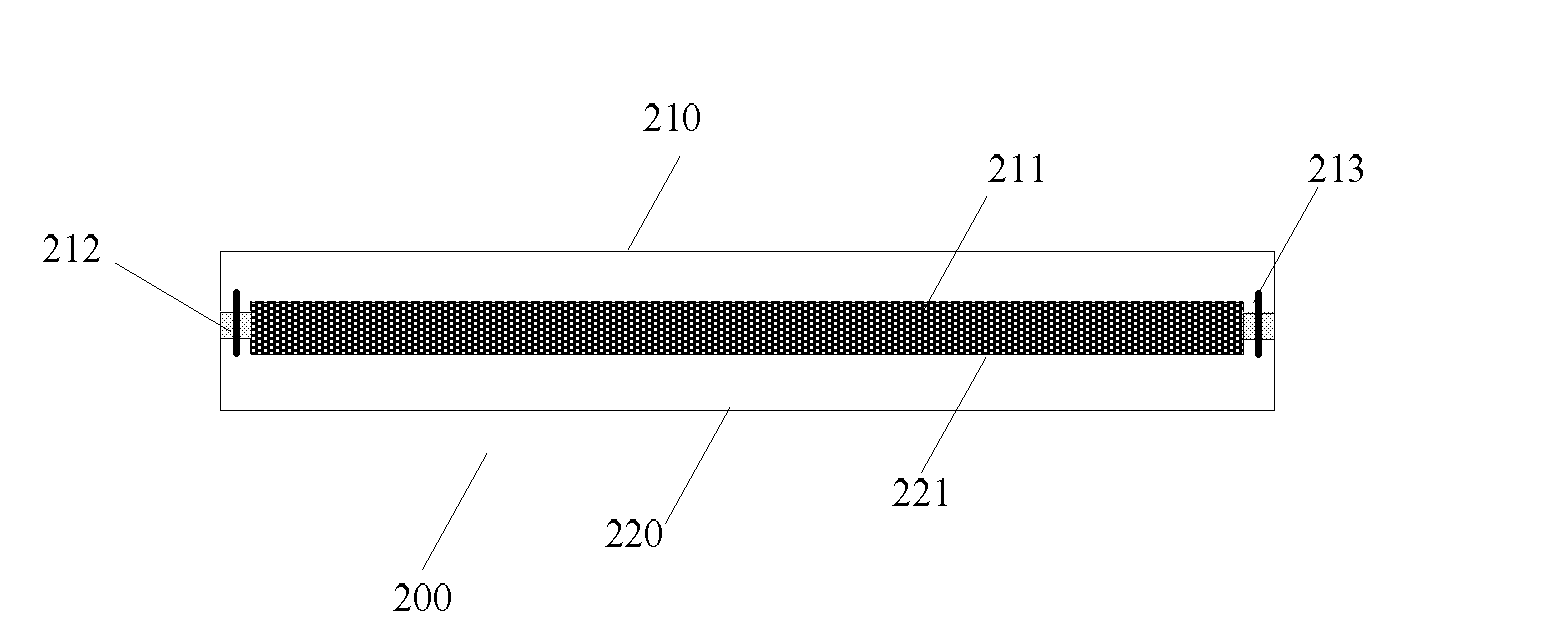

[0042] Such as figure 2 Shown is a longitudinal sectional view of a tray according to another embodiment of the present invention. In some embodiments of the present invention, the tray body 200 includes a first body 210 and a second body 220.

[0043] Wherein, the lower surface of the first body 210 has a first groove 211. The upper surface of the second body 220 has a second groove 221 that matches the first groove 211, and the first body 210 and the second body 220 are connected to each other so that the first groove 211 and the second groove 221 form the hollow structure. By providing the first groove 211 on the lower surface of the first body 210 and the second groove 221 on the upper surface of the second body 220, the processing of the first body 210 and the second body 220 is simpler and more convenient. In addition, preferably, in an embodiment of the present invention, the first body 210 and the second body 220 are connected through a first connection mechanism 213 p...

Embodiment 3

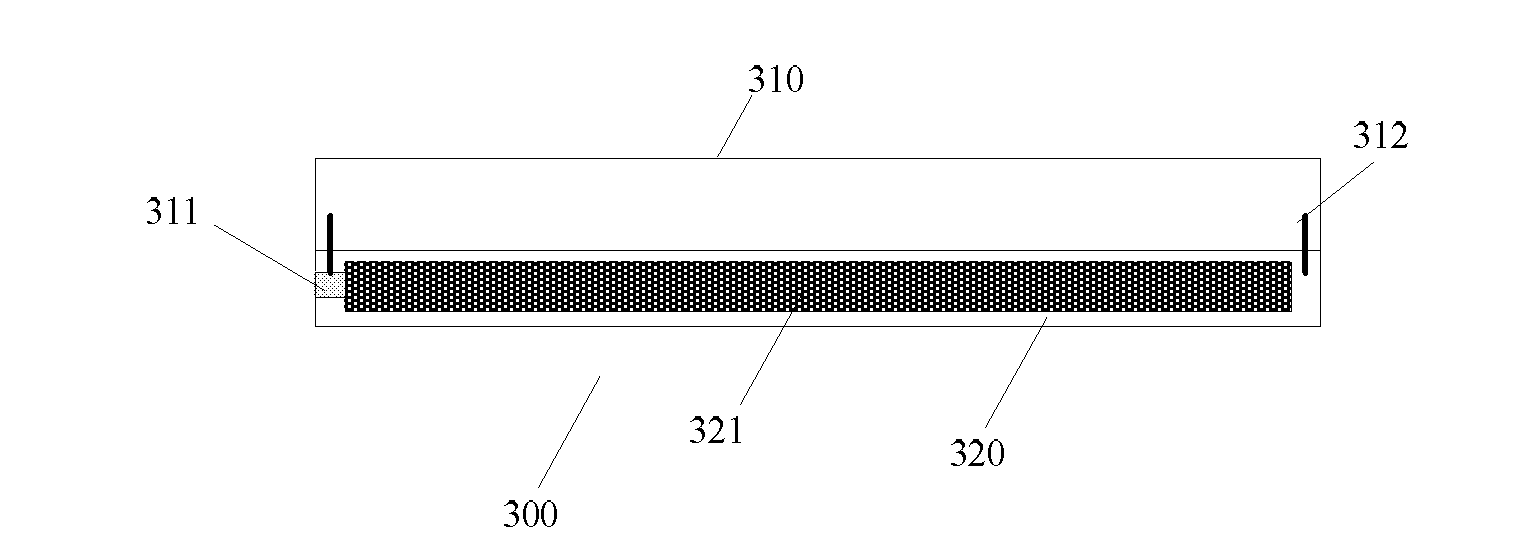

[0045] In addition, such as image 3 Shown is a longitudinal cross-sectional view of a tray according to another embodiment of the present invention. To make the design of the tray simpler, the tray body may further include a third body 310 and a fourth body 320.

[0046] Wherein, the fourth body 320 is disposed under the third body 310, such as image 3 As shown, a hollow structure 321 is formed in the fourth body 320. Preferably, the fourth body 320 and the third body 310 are connected by the second connecting mechanism 312. For example, the aforementioned second connecting device 312 may be a bolt or a pin.

[0047] In the embodiments 1-3 of the present invention, the tray body in any of the embodiments 1-3 is provided with a channel (such as figure 1 Shown channel 112, figure 2 Channel 212 shown, image 3 Channel 311 shown).

[0048] Following figure 1 Take the description as an example. The channel 112 is formed in the tray body 110, for example, it may be one or more channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com