A preparation structure of prestressed concrete slab structural reinforcement for high-speed railway

A concrete and prestressing technology, applied in the field of prestressed concrete slab structure reinforcement structure, can solve problems affecting the stability and durability of concrete slabs, improve spatial positioning accuracy and firmness, and ensure uniformity and durability, the effect of improving stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples.

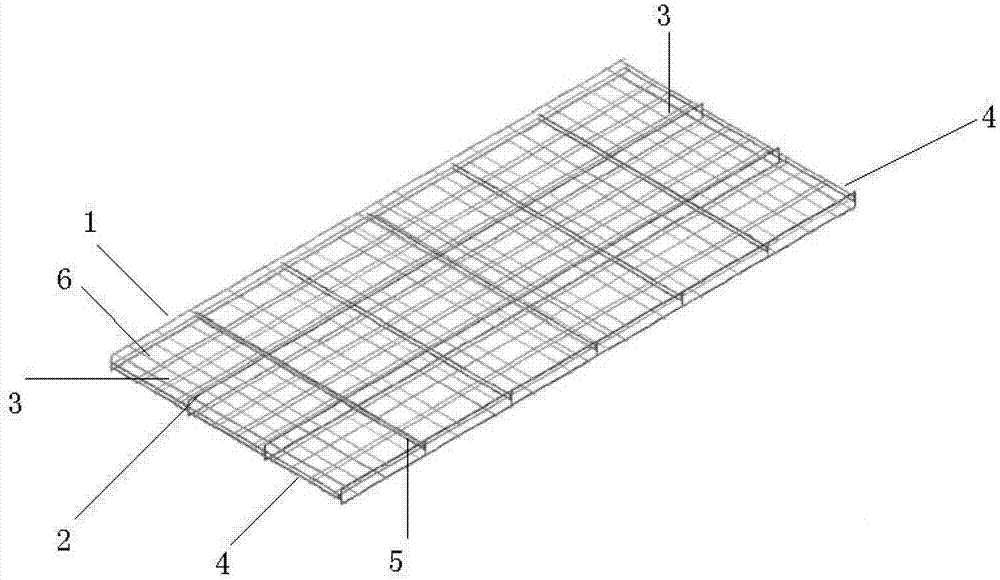

[0029] Such as figure 1 As shown, the present invention includes structural steel bars and ribs; said structural steel bars include transverse structural steel bars 3 and longitudinal structural steel bars 6; said rib bars include transverse frame ribs 1, transverse internal ribs 2, longitudinal frame ribs 4, Longitudinal internal ribs 5; the structural steel bars and ribs are connected into four layers of structural steel mesh, from top to bottom are the upper horizontal structural steel mesh, the upper longitudinal structural steel mesh, the lower longitudinal structural steel mesh, the lower layer The horizontal structural steel mesh is evenly distributed and densely arranged according to the symmetry of the center of the section, realizing the purpose of multi-point uniform force on the concrete slab; the four-layer structural steel mesh is composed of horizontal frame rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com