Motion redundancy face shovel excavating mechanism containing lengthened arm

A technology of lengthening the arm and redundancy, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of small driving force arm, single structure, high energy consumption, etc., achieve large driving force arm, improve flexibility, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

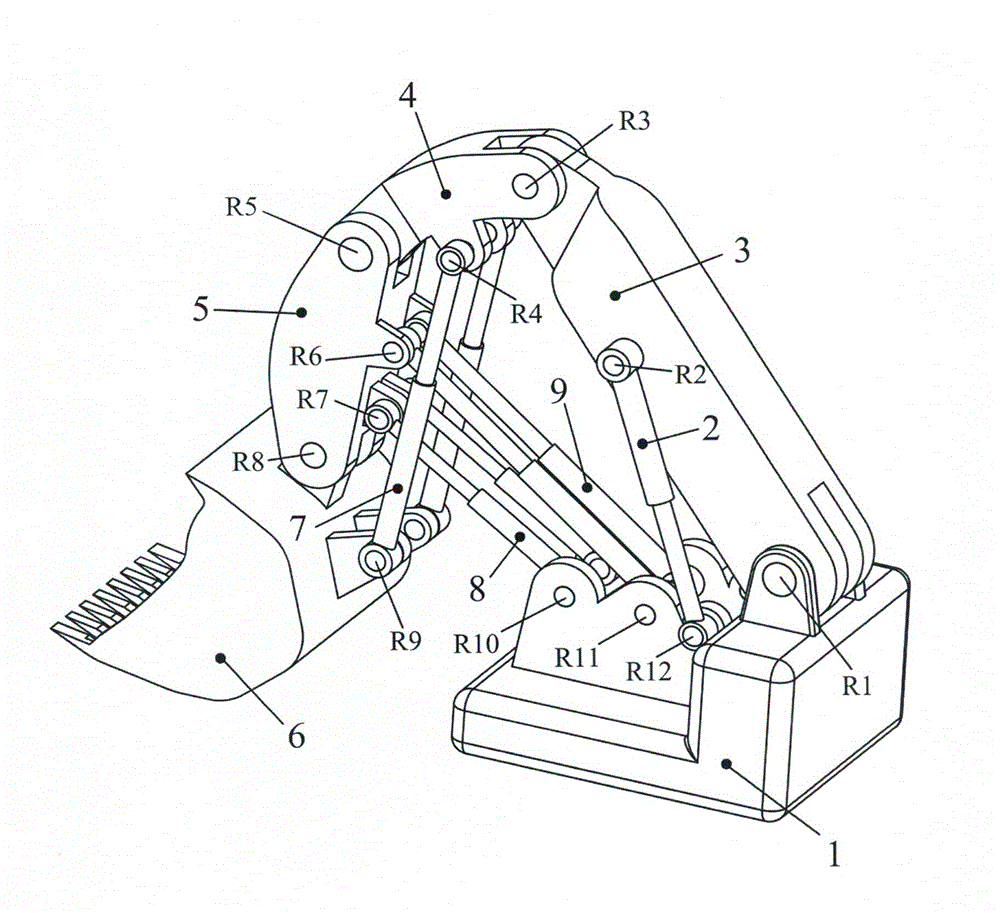

[0014] exist figure 1 In the three-dimensional schematic diagram of Embodiment 1 of the mobile redundant front shovel excavating mechanism with extended arms shown, the frame 1 and the lower end of the boom 3 are hinged through the hinge R1, and the upper end of the boom and the end of the extended arm 4 are hinged through the hinge R3 Hinged, the other end of the extended arm is hinged with one end of the stick 5 through a hinge R5, and the other end of the stick is hinged with a part of the bucket 6 through a hinge R8. The other part of the bucket is hinged with the cylinder liner ends of a pair of bucket hydraulic cylinders 7 through a hinge R9, and the piston rod ends of the pair of bucket hydraulic cylinders are hinged with the middle part of the above-mentioned elongated arm through a hinge R4. The middle part of the above-mentioned boom is hinged with the cylinder liner ends of a pair of boom hydraulic cylinders 2 through a hinge R2, and the piston rod ends of the pair ...

Embodiment 2

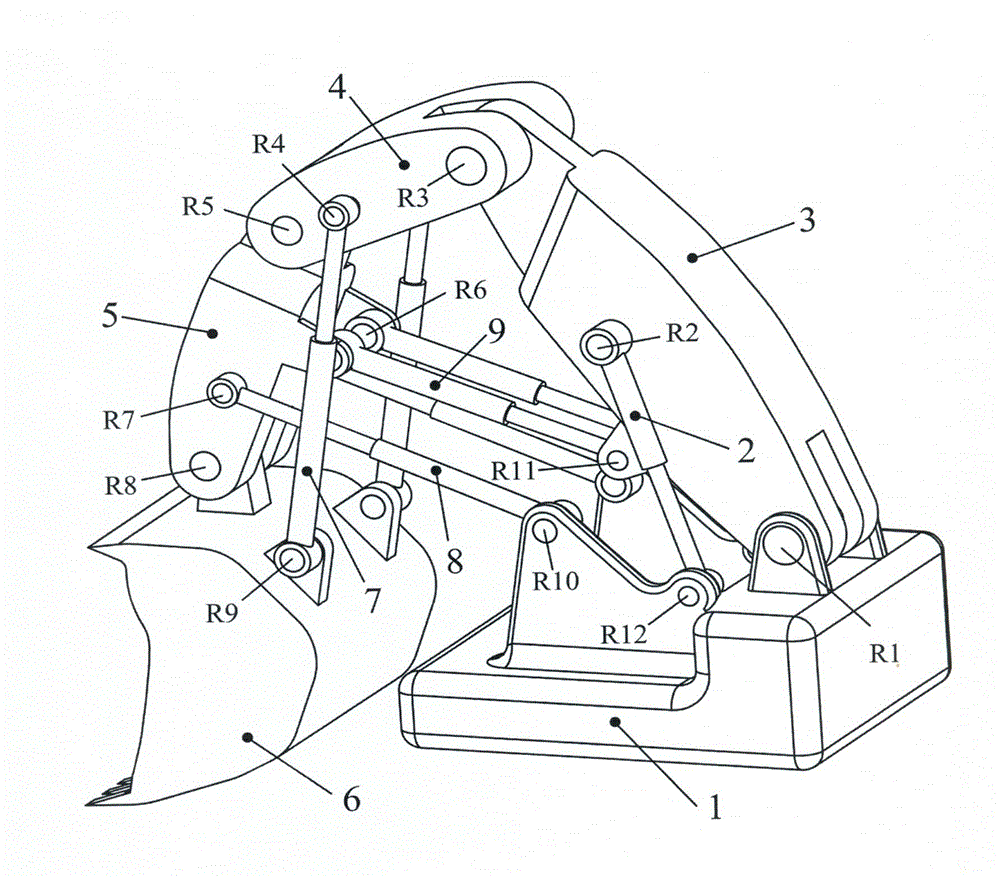

[0016] exist figure 2 In the three-dimensional schematic diagram of the embodiment 2 of the movement-redundant front shovel excavating mechanism containing the extended arm, a pair of cylinder liner ends of the drive hydraulic cylinder 9 with movement redundancy and another part on the arm 5 The ends of the piston rods of the pair of driving hydraulic cylinders are hinged with another part on the boom 3 through the hinge R11. The connections of other parts are all the same as in Embodiment 1.

Embodiment 3

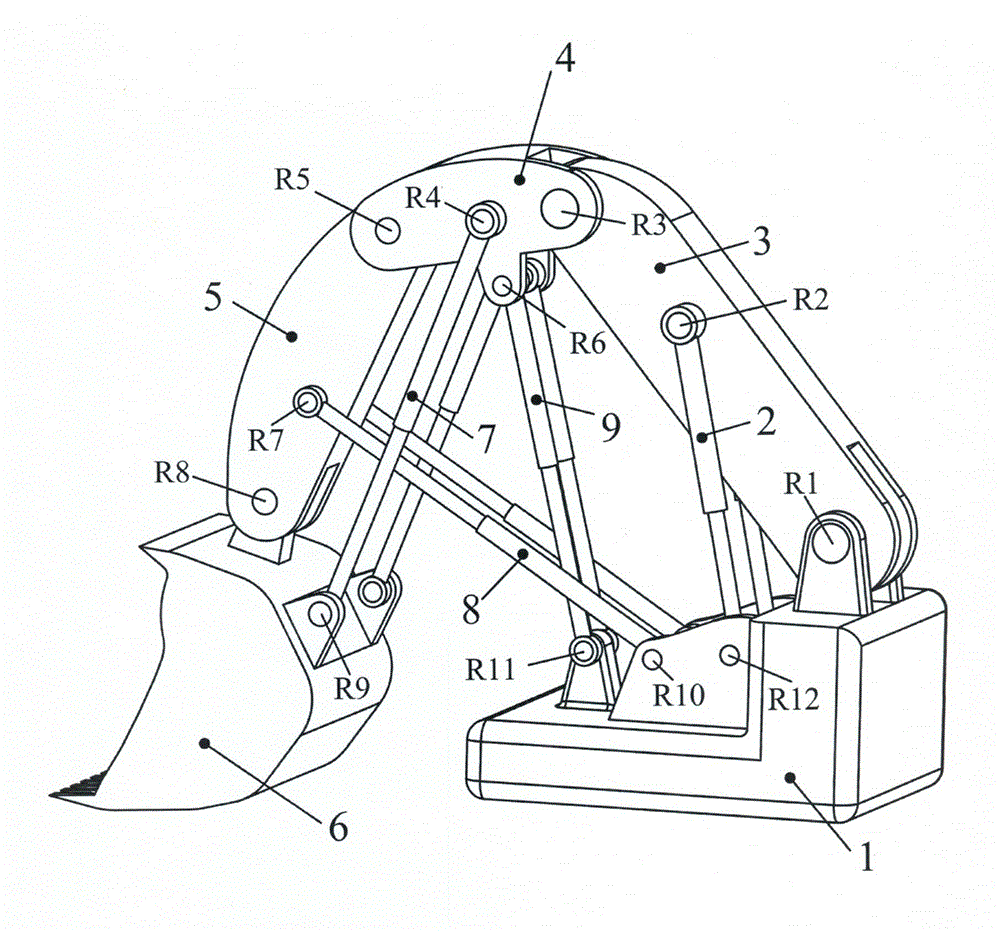

[0018] exist image 3 In the three-dimensional schematic diagram of the embodiment 3 of the movement redundant front shovel excavating mechanism containing the extended arm, a pair of cylinder liner ends of the drive hydraulic cylinder 9 with movement redundancy and another part on the extended arm 4 The hinge R6 is hinged, and the ends of the piston rods of the pair of driving hydraulic cylinders are hinged with another part on the frame 1 through the hinge R11. The connections of other parts are all the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com