Movable type hydraulic mounting machine for coal mine roadway support bracket

A coal mine roadway, mobile technology, applied in pillars/supports, mining equipment, earth-moving drilling and other directions, can solve the problems of inability to use large-scale machinery and equipment, threatening the personal safety of workers, affecting production efficiency, etc., to reduce the labor intensity of workers, The effect of improving the working environment and increasing the scope of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

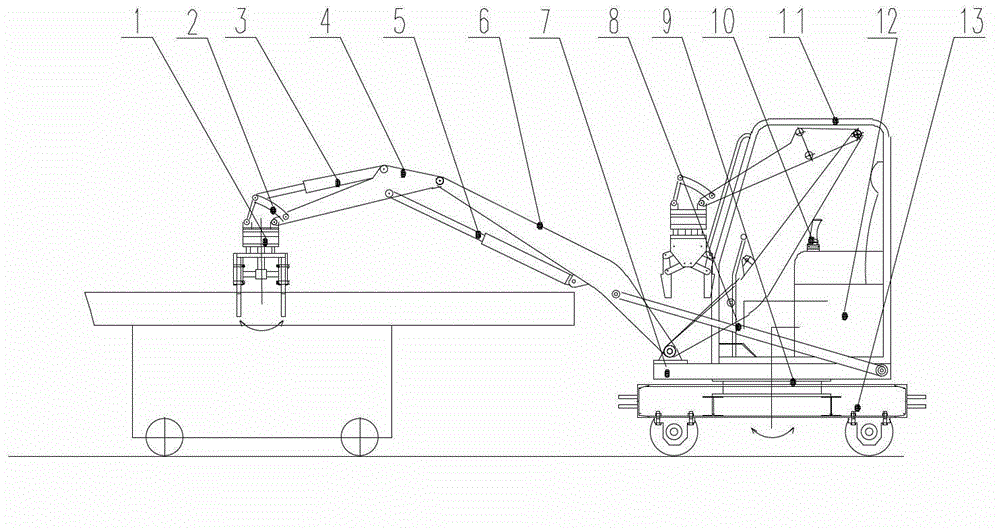

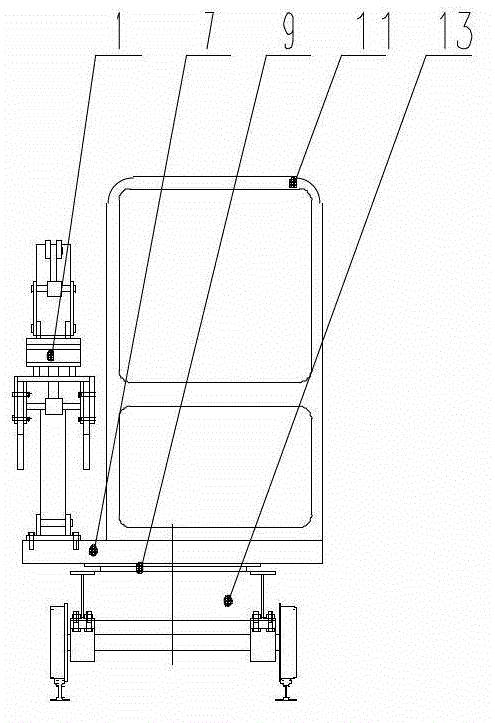

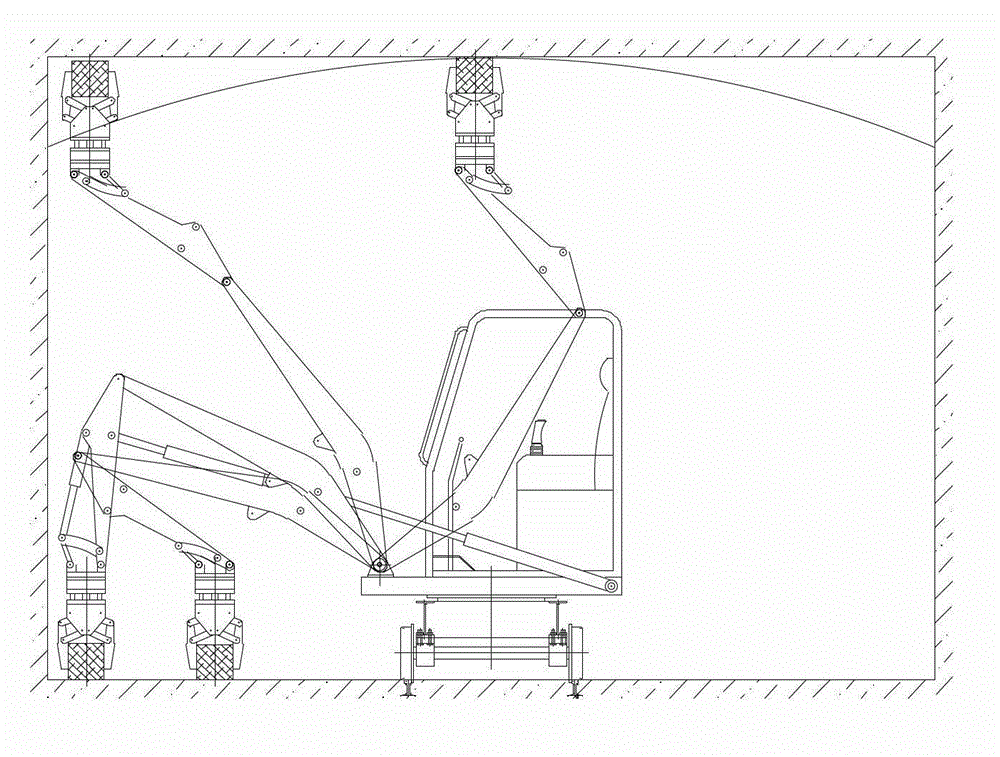

[0013] Such as figure 1 and figure 2 As shown, a mobile hydraulic coal mine roadway support bracket installation machine consists of a manipulator 1, a connecting rod group 2, a turning cylinder 3, a stick 4, a stick cylinder 5, a main arm 6, a main arm cylinder 8, a chassis 7, The rotary ring gear 9, the operating handle 10, the driver's cab 11, the hydraulic system 12 and the wheeled walking mechanism 13 are composed. The manipulator 1 is connected to the front end of the turning cylinder 3, and the rear end of the turning cylinder 3 is connected to the stick 4. The stick 4 is connected with the manipulator 1 to form the first four-bar mechanism; the stick 4 is connected with the main arm 6, the main arm 6 is connected with the rear end of the stick cylinder 5, and the front end of the stick cylinder 5 is connected with the The sticks 4 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com