Follower rotary valve for plane oil distribution

An oil distribution and follow-up technology, which is applied in the direction of machines/engines, liquid fuel engines, fluid pressure actuators, etc., can solve problems affecting normal operation and safety, low efficiency, and high cost, so as to improve reliability and oil distribution The effect of high efficiency, simple overall structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

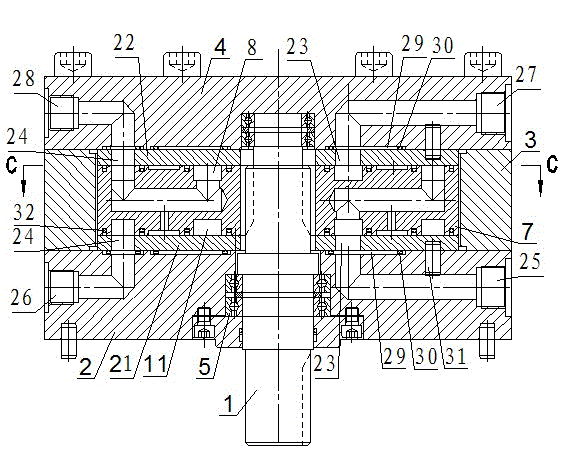

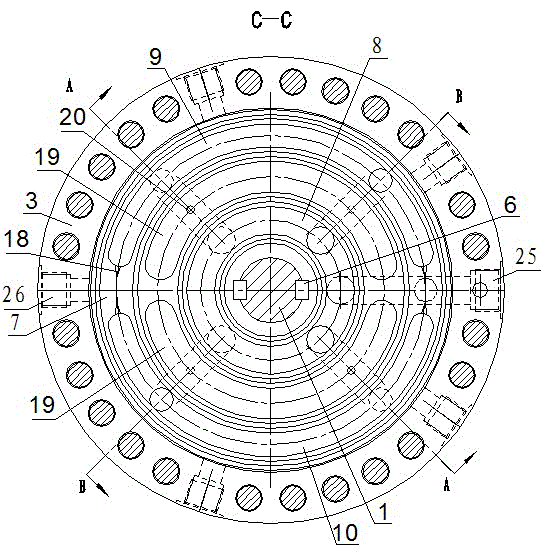

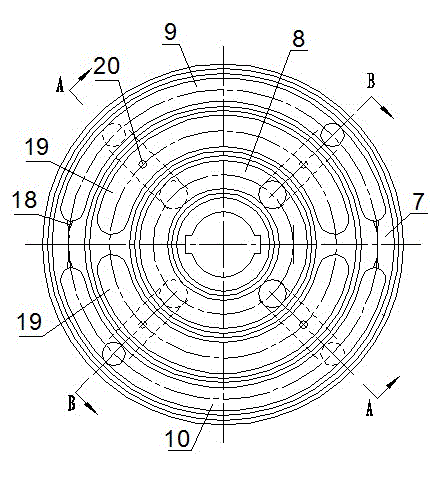

[0025] Such as Figure 1 to Figure 5 As shown, the follow-up rotary valve with plane oil distribution in this embodiment includes a central shaft 1, an end cover 2 fixedly connected by several bolts, a valve body 3 and a bottom cover 4, and the inner end of the central shaft 1 is installed through a bearing 5. In the end cover 2, the valve body 3 and the bottom cover 4, the outer end of the central shaft 1 is provided with a structure for transmitting torque such as a keyway, and a valve core 7 is provided on the central shaft 1 in the valve body 3 through a transmission key 6. The upper end surface of the spool 7 is provided with an annular groove 8 and two symmetrically distributed arc-shaped oil distribution grooves 9, 10, and the lower end surface of the spool 7 is provided with an annular groove 11 and two symmetrically distributed arc-shaped oil distribution grooves. Oil grooves 12 and 13, the two oil distribution grooves 9 and 12, 10 and 13 on both ends have the same ph...

Embodiment 2

[0031] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is: on the adjacent end surfaces of the end cover 2 and the floating side plate 21, on the adjacent end surfaces of the bottom cover 4 and the adjacent floating side plate 22, both There is a compensation pressure oil chamber 33, and a sealing sleeve 34 is arranged in the compensation pressure oil chamber 33, and a sealing ring is provided between the sealing sleeve 34, the end cover 2 and the side wall of the floating side plate 21, and a sealing ring is arranged between the sealing sleeve 34 and the bottom A sealing ring is also provided between the cover 4 and the side wall of the floating side plate 22; between the connecting oil holes 24 of each floating side plate 21, 22 and the two ends of the internal oil passage of the end cover 2 or the bottom cover 4, a sealing ring is provided. There is a positioning cavity, and a positioning sleeve 35 is arranged in the positioning cavity, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com