Method for manufacturing semiconductor

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as the adverse effects of oxidized wafers, increase production costs, and consumption, so as to reduce production costs, reduce consumption, and avoid The effect of particulate matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The features and technical effects of the technical solution of the present invention will be described in detail below with reference to the accompanying drawings and in combination with exemplary embodiments.

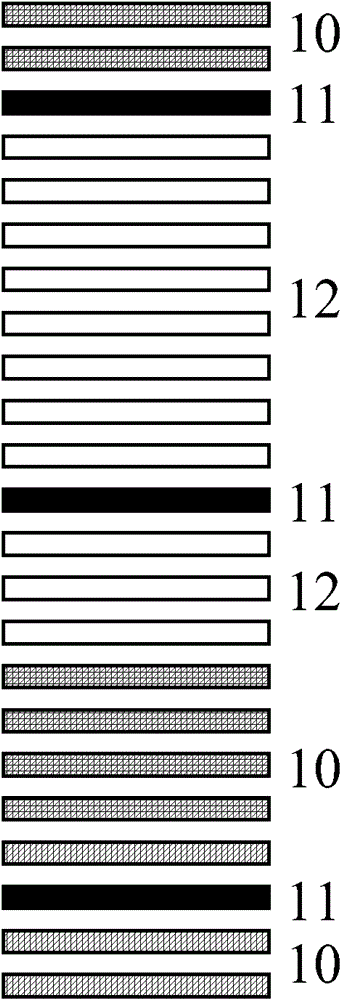

[0018] Firstly, a wafer to be oxidized 12 , a dummy wafer 10 , and a monitor wafer 11 are provided. When the wafer 12 to be oxidized does not fully occupy the thermal oxidation equipment, a certain number of dummy wafers 10 need to be placed in the thermal oxidation equipment, so that the total wafers can fill the thermal oxidation equipment as much as possible to eliminate the load effect. It can make the oxidation effect of each part of the oxidation furnace and each batch consistent, see the attached figure 1 .

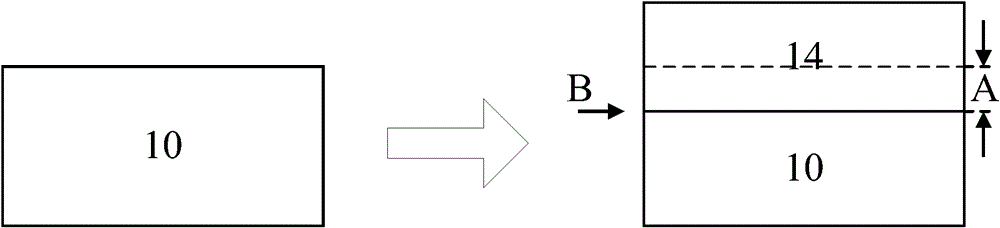

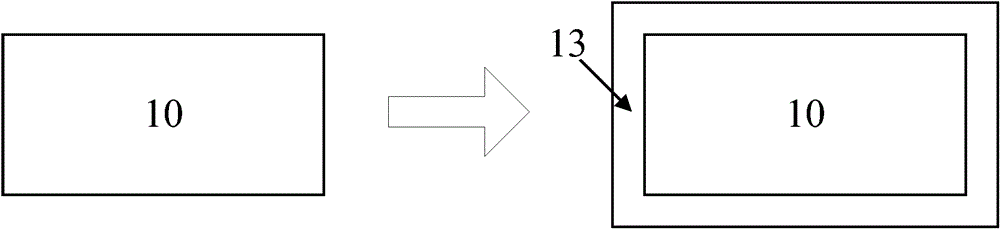

[0019] Before each wafer is put into thermal oxidation equipment for thermal oxidation process, a layer of protective film 13 is deposited on the outer surface of the dummy wafer 10, so that the protective film 13 completely covers the dummy wafer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com