Hexagonal resonant cavity substrate integrated waveguide filter

A substrate-integrated waveguide and resonant cavity technology, applied in waveguide devices, electrical components, circuits, etc., can solve problems such as low Q value and inflexible structural design, and achieve high no-load quality factor, good flexibility, highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

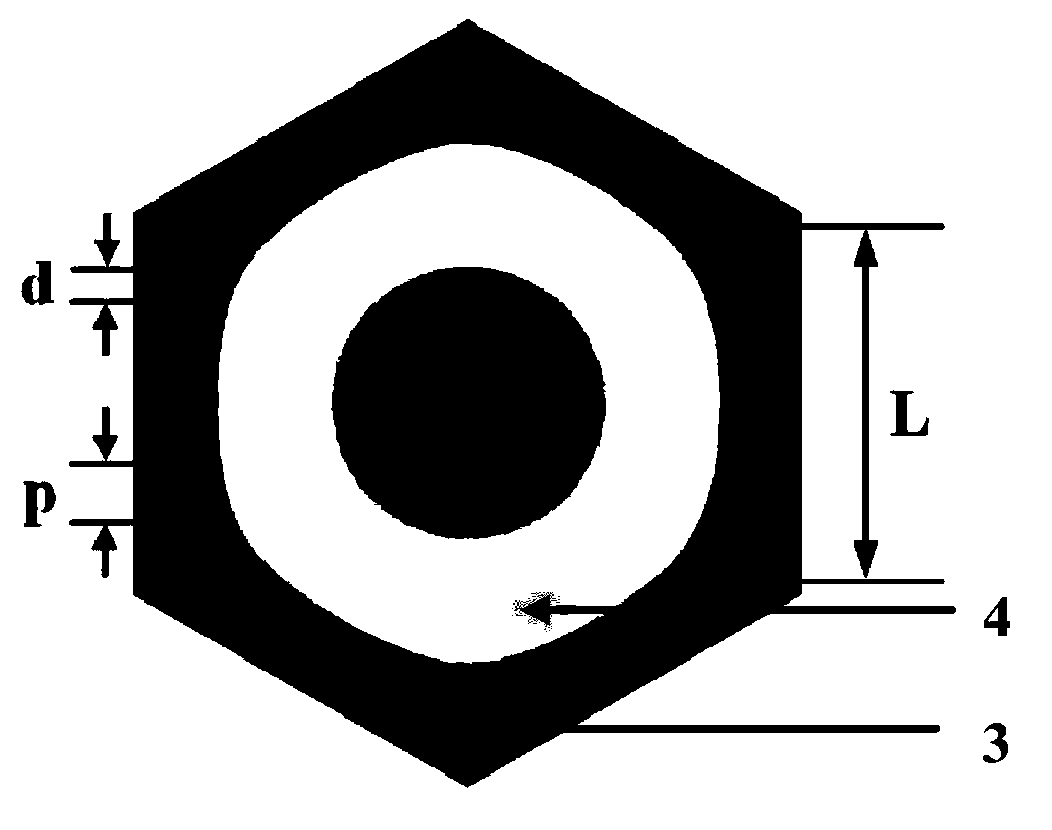

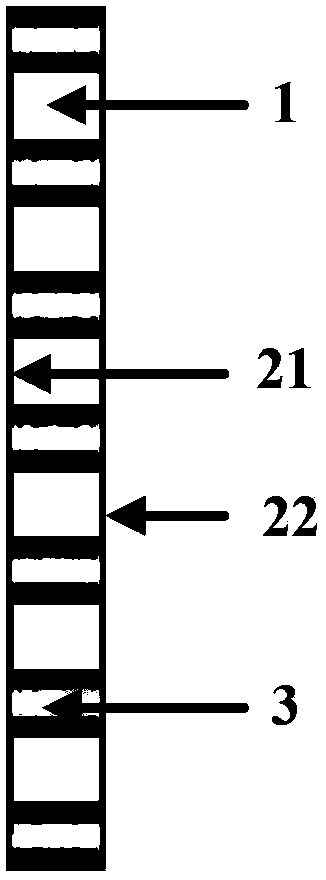

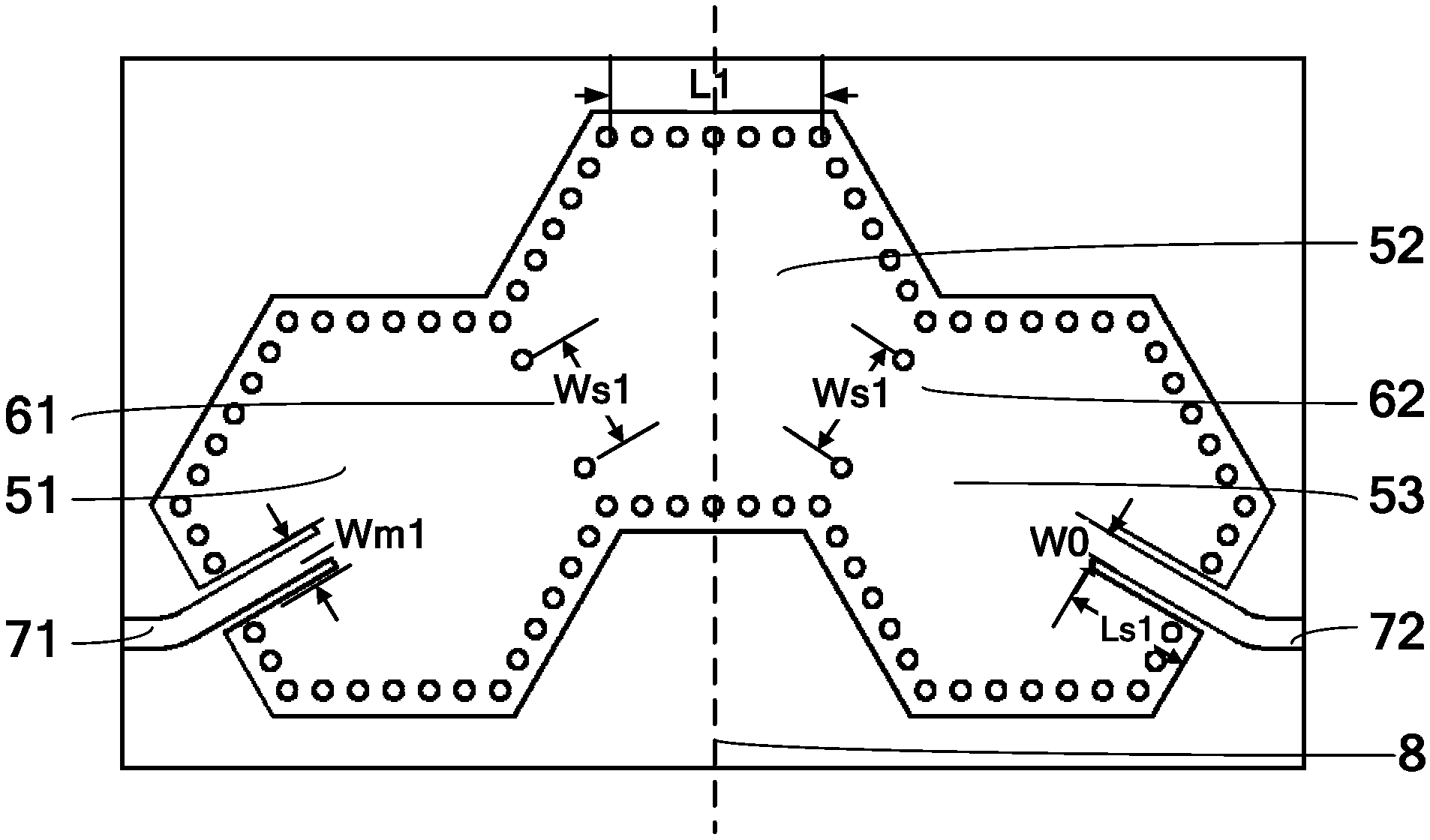

[0015] Embodiment 1: as Figure 1a , Figure 1b and figure 2 As shown, the hexagonal resonant cavity substrate integrated waveguide filter, the filter includes a dielectric substrate 1 and the upper surface metal copper 21 and the lower surface metal copper 22 respectively located on the upper surface and the lower surface of the dielectric substrate 1; The through holes of the metallization 3 penetrate the dielectric substrate 1 and conduction with the metal copper 21 on the upper surface and the metal copper 22 on the lower surface, and the array of the metallization 3 forms a regular hexagonal first hexagonal resonant cavity connected in sequence 51. The second hexagonal resonant cavity 52 and the third hexagonal resonant cavity 53; Axis 8 is mirror symmetrical but not adjacent; the upper right side of the first hexagonal resonant cavity 51 coincides with the lower left side of the second hexagonal resonant cavity 52 and is provided with a first inductive coupling window ...

Embodiment 2

[0018] Embodiment 2: as Figure 1a , Figure 1b and image 3 As shown, the hexagonal resonant cavity substrate integrated waveguide filter, the filter includes a dielectric substrate 1 and the upper surface metal copper 21 and the lower surface metal copper 22 respectively located on the upper surface and the lower surface of the dielectric substrate 1; The through holes of the metallization 3 penetrate the dielectric substrate 1 and conduction with the metal copper 21 on the upper surface and the metal copper 22 on the lower surface, and the array of the metallization 3 forms a regular hexagonal first hexagonal resonant cavity connected in sequence 51, the second hexagonal resonant cavity 52 and the third hexagonal resonant cavity 53; the first hexagonal resonant cavity 51, the second hexagonal resonant cavity 52 and the third hexagonal resonant cavity 53 with The apex mode is evenly arranged; the upper right side of the first hexagonal resonant cavity 51 coincides with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com