Micro-driving motor and lower spring for same

A technology of micro-drive motors and shrapnel, applied to circuits, electrical components, electromechanical devices, etc., can solve problems such as long welding time, unfavorable soldering, and heating of lens drive devices, and achieve high-efficiency welding methods, easy to ensure welding quality, and fast The effect of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (Embodiment 1, lower shrapnel assembly)

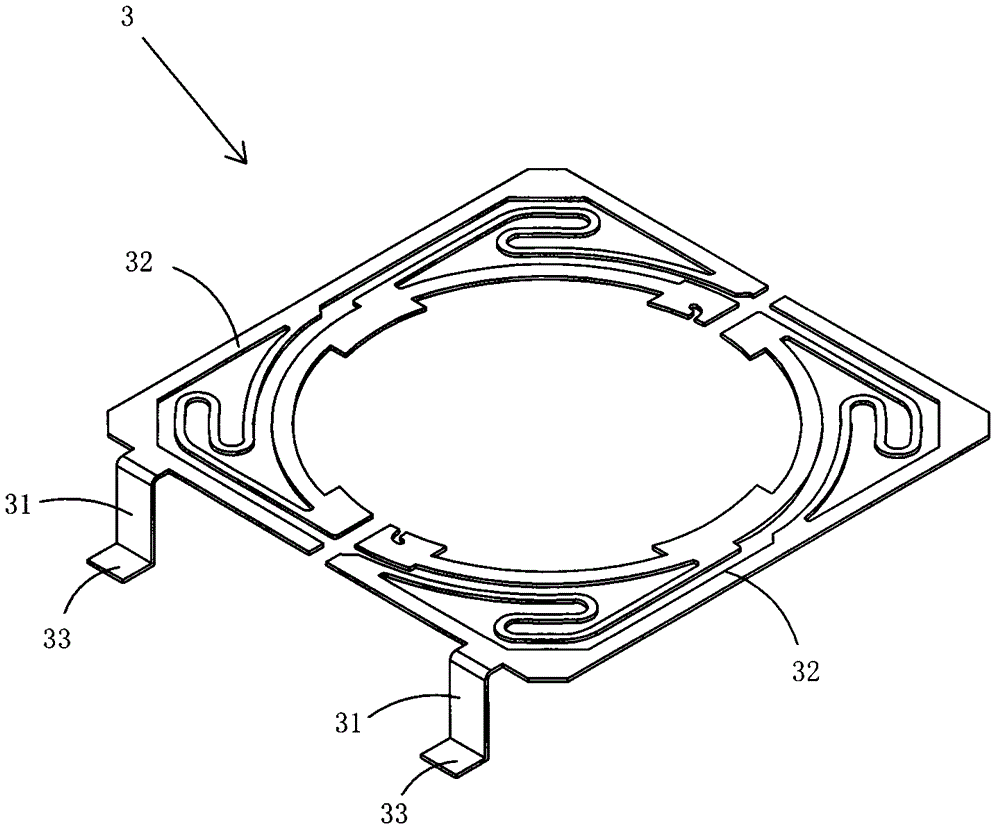

[0014] figure 1 It is a schematic three-dimensional structure diagram of the lower spring assembly in the present invention, showing a specific implementation of the coil in the present invention.

[0015] Present embodiment is a kind of spring under the miniature driving motor, see figure 1 As shown, it includes two shrapnel bodies 32 that are insulated from each other and an electrical contact pin 31 that extends vertically downward from one side of each elastic segment body 32; The electrical connection pin 31 protrudes away from the lower spring assembly 3 and forms a fixing pin 33 .

Embodiment 2

[0016] (Embodiment 2, miniature drive motor)

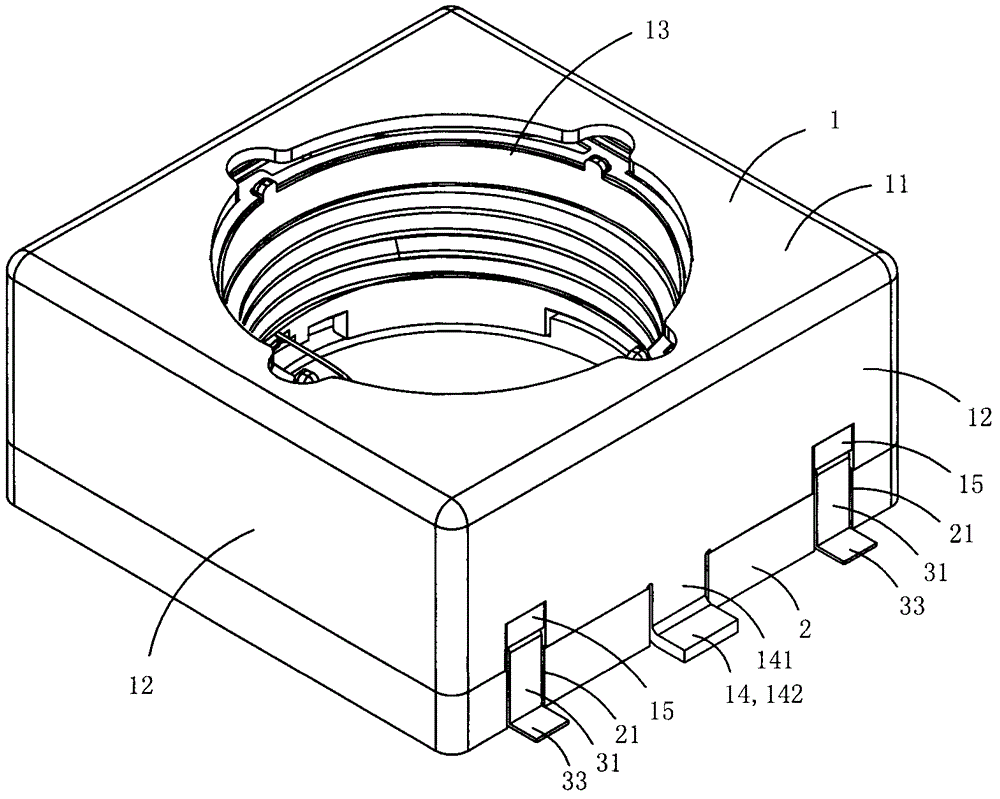

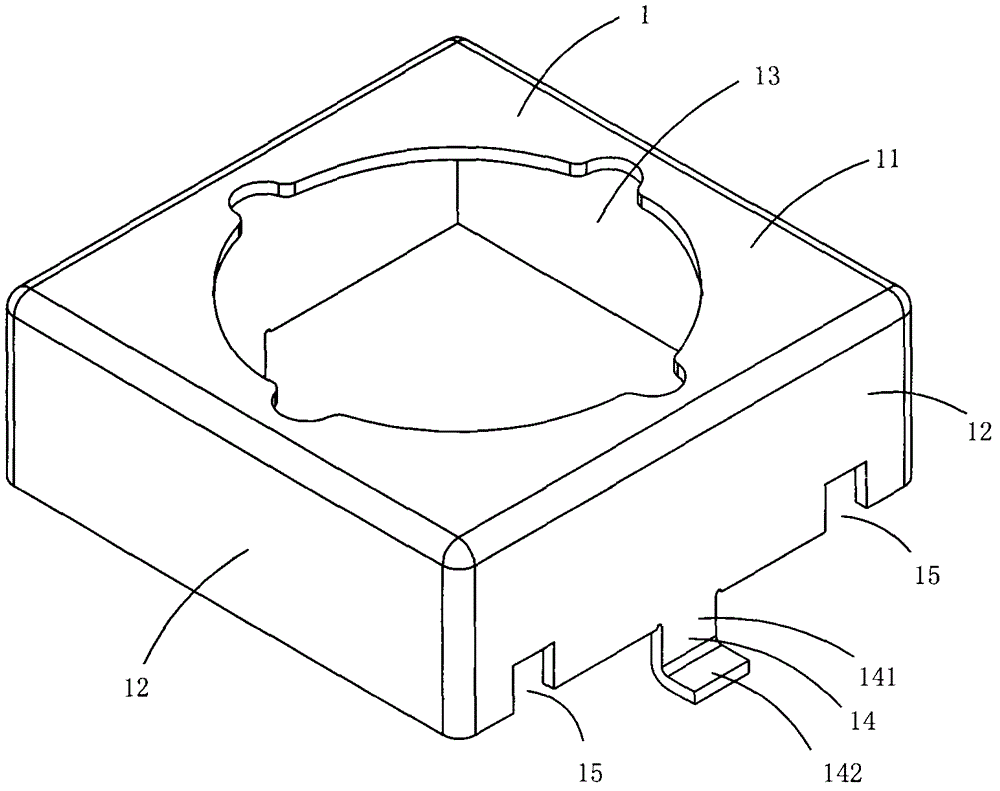

[0017] Figure 2 to Figure 4 A specific embodiment of the micro drive motor in the present invention is shown, wherein figure 2 It is a schematic diagram of a three-dimensional structure of the micro drive motor in the present invention; image 3 yes figure 2 A schematic diagram of a three-dimensional structure of the upper cover in the micro drive motor shown; Figure 4 yes image 3 A top view of the upper cover shown.

[0018] This embodiment is a kind of miniature drive motor that adopts above-mentioned embodiment 1 to make, see Figure 2 to Figure 4 As shown, it includes a housing composed of an upper cover 1 and a base 2, and a lower spring assembly 3 fixed in the housing; the upper cover 1 includes a top wall 11 and a plurality of side walls 12, and the center of the top wall 11 A light-transmitting hole 13 is provided; two opposite side walls 12 are provided with positioning feet 14 protruding vertically toward the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com