Savoury food concentrate

A technology for concentrates, foods, applied in the field of preparing such food concentrates, ready-to-eat foods, preparing broths, sauces, soups, gravies or used as condiments, which can solve problems such as consumer dislikes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

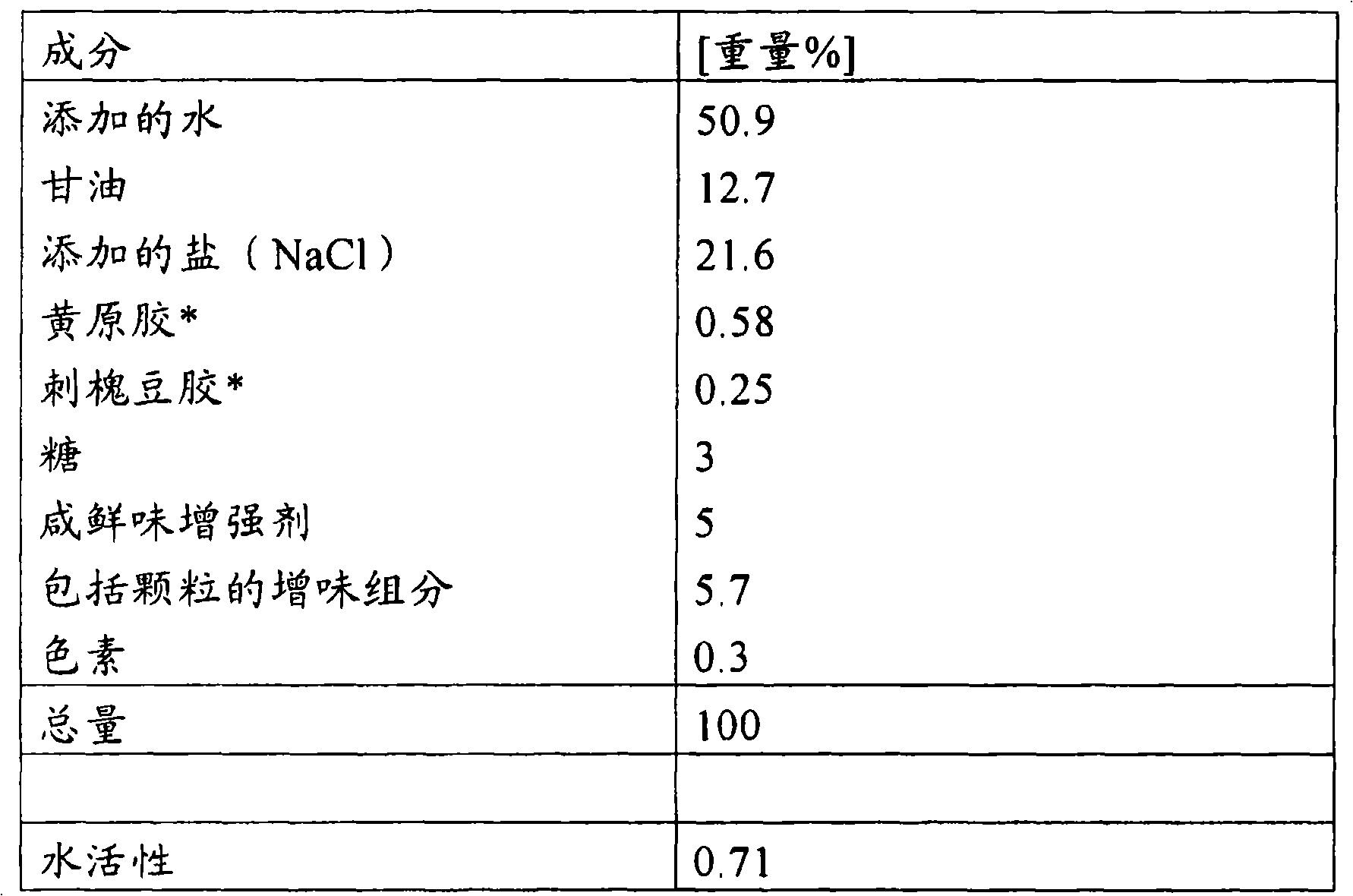

[0128] Example 1: Concentrated broth composition in shape stable gel form containing xanthan gum-LBG (gelling system) and glycerol (polyol)

[0129]

[0130] * gelling system

[0131] The composition was prepared using an (automated) IKA laboratory reactor (batch size: 2 kg). The liquid ingredients (water and polyol) were heated to 75°C, then the remaining ingredients (except vegetables) were added followed by mixing under high shear for 3 minutes. Subsequently, the mixture was heated to 85° C., and vegetables were added to the mixture. This mixture was then homogenized using high shear at 85°C for 3 minutes, followed by pasteurization (3 minutes at 85°C). The savory concentrate is then packaged by filling jars and tubs with the concentrate and then sealing the jars and tubs.

[0132] Water activity (aw) was measured using Aqualab (Water activity Meter, 3TE series, IUL Instruments). Since water activity is temperature dependent, samples were kept at 25°C overnight befo...

Embodiment 2

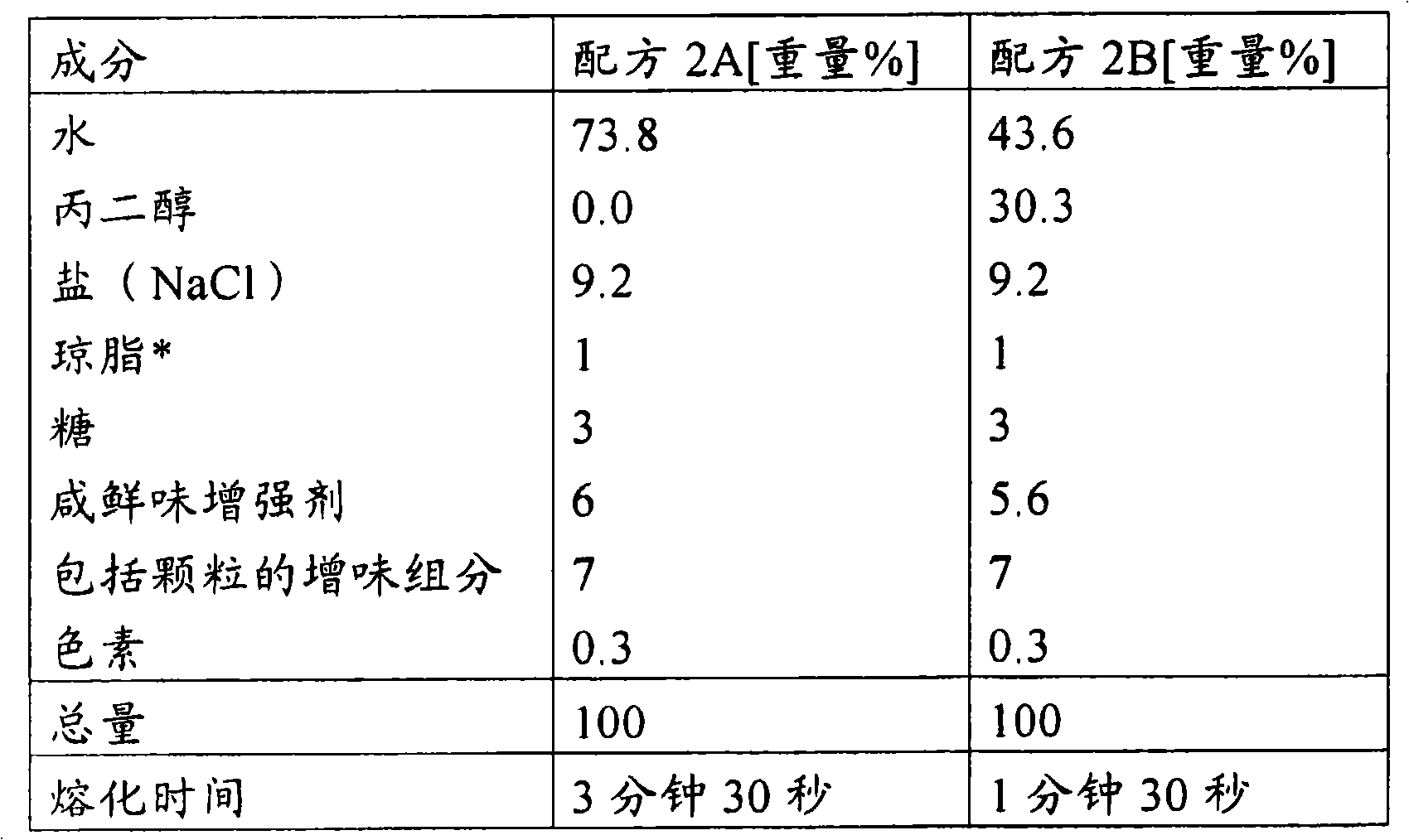

[0133] Example 2: Concentrated broth composition in shape stable gel form containing agar (gelling system) and propylene glycol (polyol)

[0134]

[0135] * gelling system

[0136] Preparation: The formulation was prepared as in Example 1 except that it was not pasteurized at 85°C for 3 minutes. Instead, the concentrate was heated at 100°C for 2 minutes.

[0137] Melting times were measured visually. For each sample, one jelly was melted into a pan with a surface temperature of 150°C. During melting, photographs were taken regularly to compare samples and record the time required for the jelly to completely melt. Jelly melting times are shown in the table.

[0138] result : Bouillon jelly with propylene glycol (Example 2B) exhibits better melting behavior, for example in terms of lower melting time and lower splashing and fizzing, than a control sample without propylene glycol (Example 2A) .

Embodiment 3

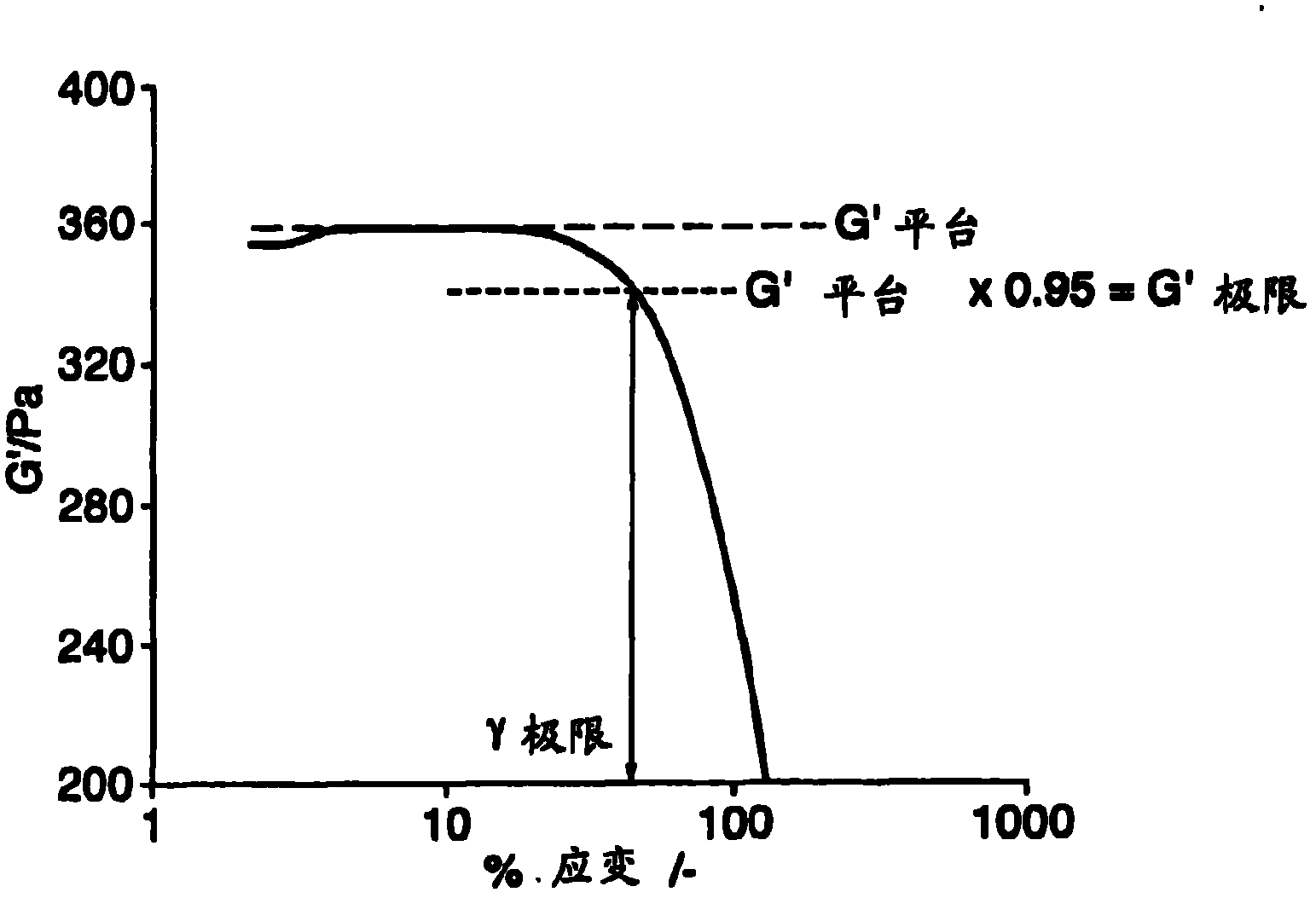

[0140] Example 3: Xanthan Gum-LBG Model Salty Fresh Gel Containing Glycerin and Salt

[0141]

[0142] * gelling system

[0143] The gel of Example 3 was prepared by adding water and polyol to a glass jar and mixing on a common laboratory grade hot plate with magnetic stirring. Salt (NaCl) was added and the mixture was stirred and heated to 80-90°C. The dry gelling system ingredients (xanthan gum and LBG) were then added to the mixer. The mixture was stirred at 80-90°C and maintained at this temperature for about 30 minutes or until the gelled system dissolved (no lumps present). The entire above process was carried out with the glass jars kept closed to avoid evaporation of water during jelly preparation. The mixture is filled into containers or molds and kept closed to cool at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com