Vegetable pot-seedling bevel gear planetary gear train transplanter

A technology of planetary gear train and bevel gear, which is applied in the field of vegetable pot seedling transplanting machine, can solve the problems of missing seedlings, lack of seedlings, damaged seedling planting quality, missing planting, and large number of assistants, so as to ensure planting quality and survival rate , solve the effect of uneven plant spacing and accurate planting spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

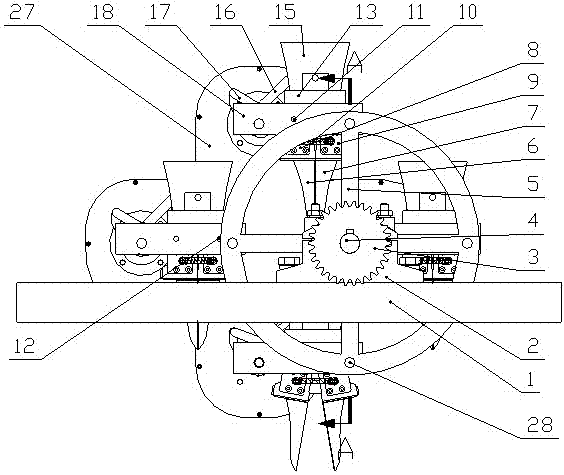

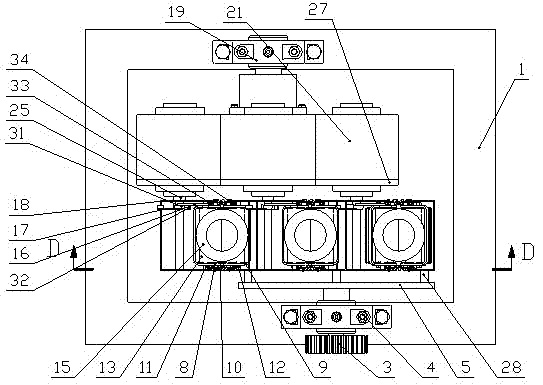

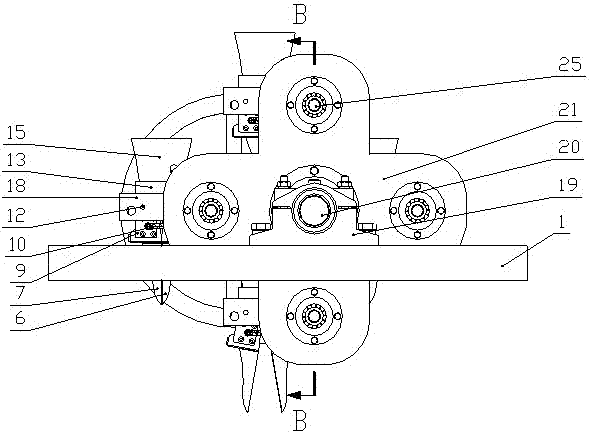

[0020] Vegetable pot seedling bevel gear planetary gear train planter as shown in the accompanying drawing comprises frame 1, wheel disk drive assembly, planetary bevel gear assembly, transplanting assembly; Wheel disk drive assembly and planetary bevel gear assembly are fixed on the machine On frame 1, there are multiple sets of implanted assemblies with the same structure between the wheel drive assembly and the planetary bevel gear assembly, and the number of implanted assemblies is set to 4 or 6 groups;

[0021] The wheel disk drive assembly includes a sprocket 3, a sprocket shaft 4, a first support 2, a drive wheel 5, and a pin shaft 28; the sprocket shaft 4 is installed on the frame 1 through the first support 2, and one end of the sprocket shaft 4 is connected to the The driving wheel 5 is fixedly connected, the other end of the sprocket shaft 4 is fixedly connected to the sprocket 3, and four pin shafts 28 are evenly arranged on the edge of the driving wheel 5;

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com