Double-motor two-way pre-tightening active loosening type safety belt

A seat belt and dual motor technology, applied in the field of seat belts, can solve the problems of not considering the difference in the tension change of the waist and shoulder seat belts, low stability and reliability, unstable transmission ratio, etc., so as to reduce the wearing tension. , convenient and comfortable to wear, the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] Wearing assistance:

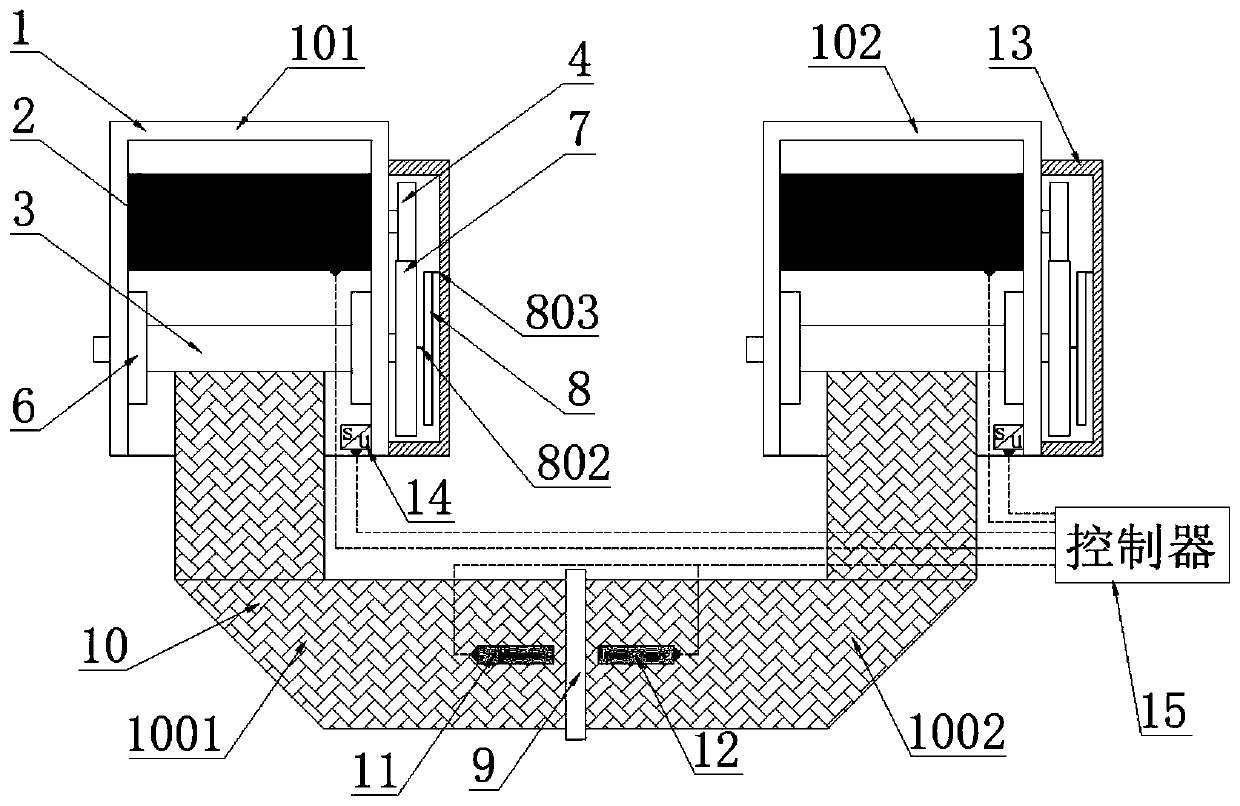

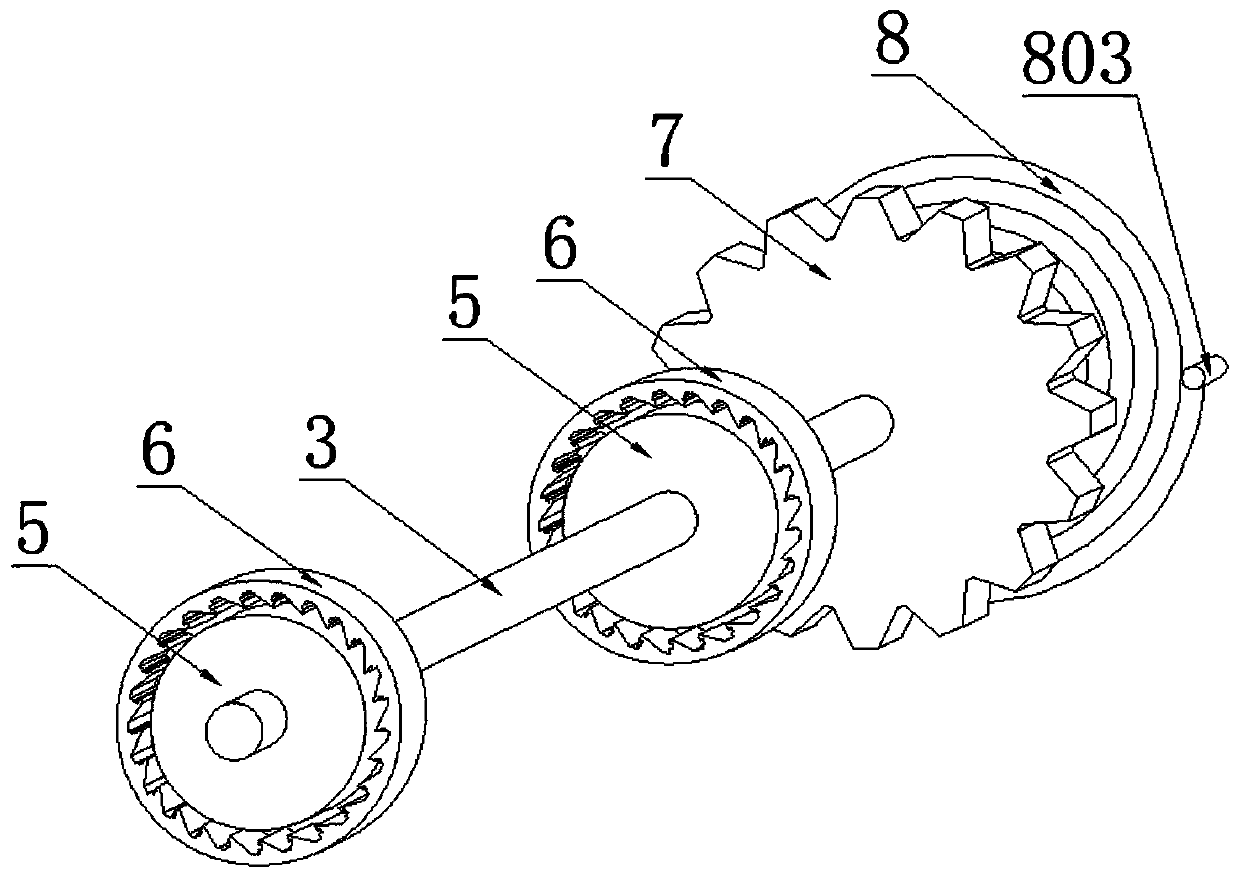

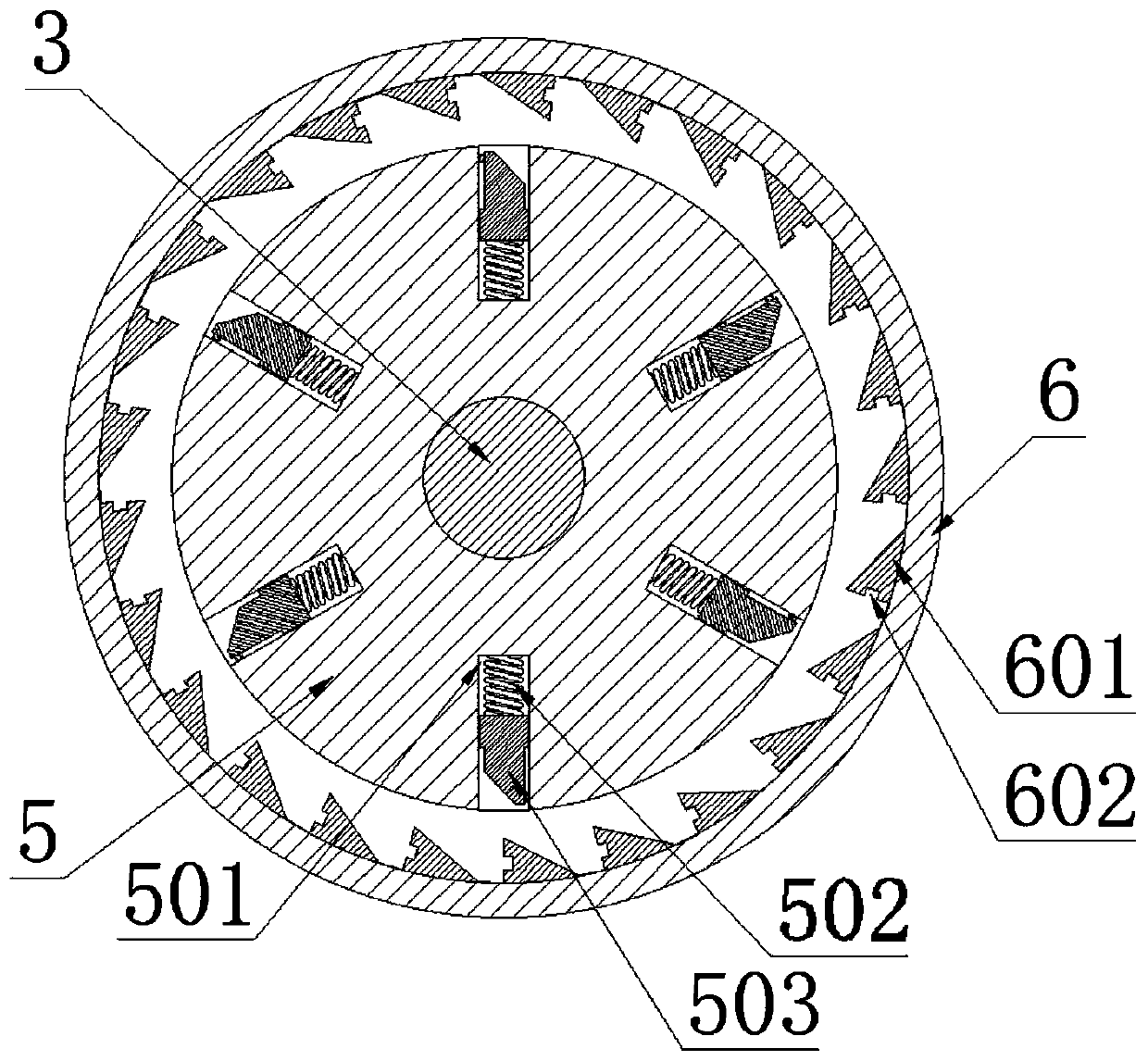

[0040] Such as Figure 1-5 As shown, when wearing a seat belt, the passenger pulls the seat belt webbing 10 through the deadbolt 9, and the seat belt webbing 10 stretches out. At this time, two displacement sensors 14 detect the seat belt extension signal and send the signal to the control 15, the controller 15 controls the two preload motors 2 to turn on and reverse, the output torque of the preload motor 2 is transmitted to the large gear 7 through the pinion 4, and the large gear 7 drives the rewinding shaft 3 to rotate, and the rewinding shaft 3 overcomes the scroll The resistance of the spring 8 continuously sends the seat belt webbing 10 according to the pulling speed of the passenger, thereby reducing the seat belt wearing resistance; before the lock tongue 9 is not inserted into the seat belt buckle, if the passenger stops pulling the seat belt webbing 10, the displacement The safety belt extension signal that the sensor 14 delivers to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com