Jacking rotary-type numerical control high-pressure washer

A high-pressure cleaning machine and high-pressure cleaning technology, applied in cleaning methods and appliances, cleaning methods using liquids, cleaning methods using gas flow, etc., can solve the problems of complex equipment structure, high manufacturing cost, and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

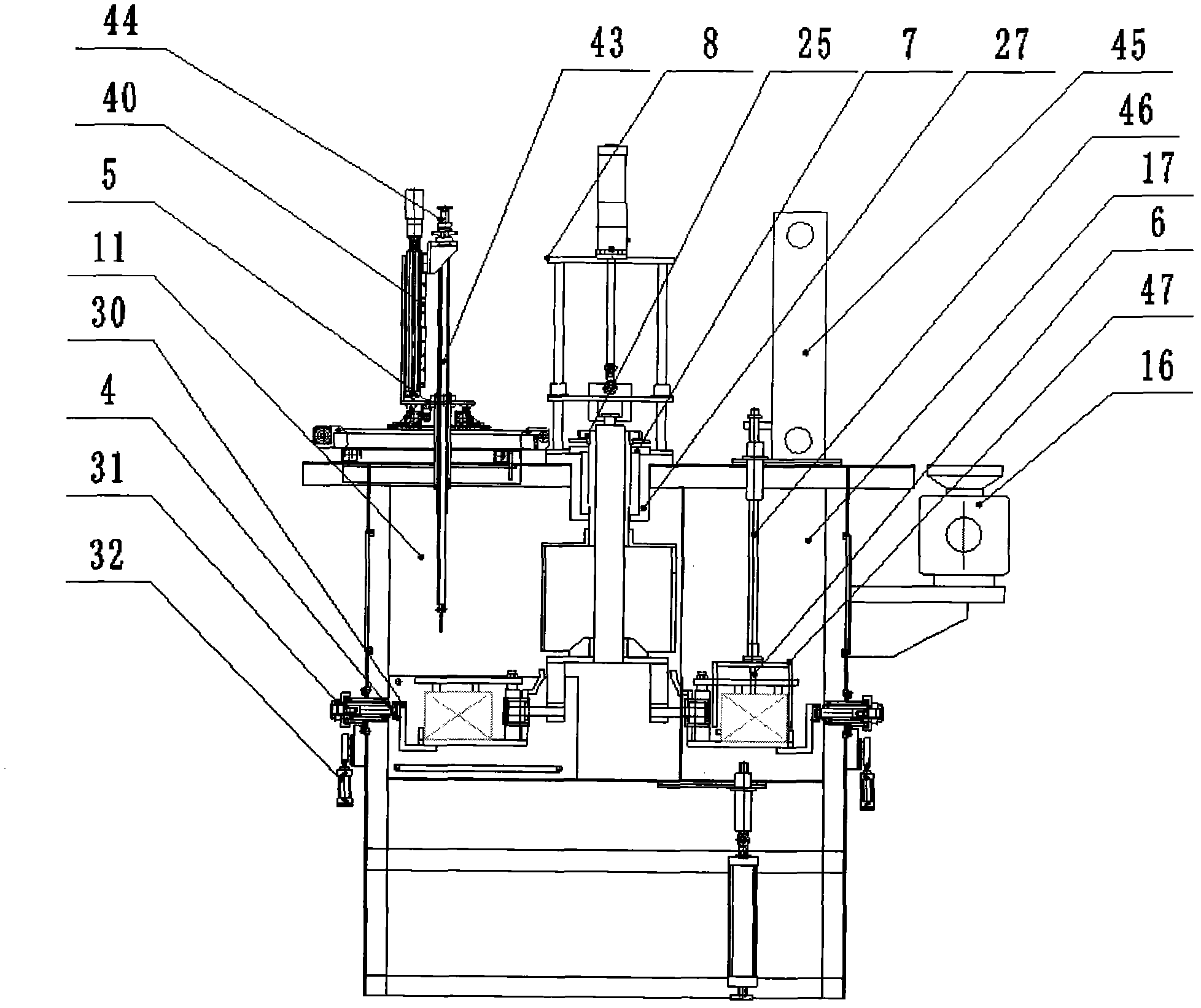

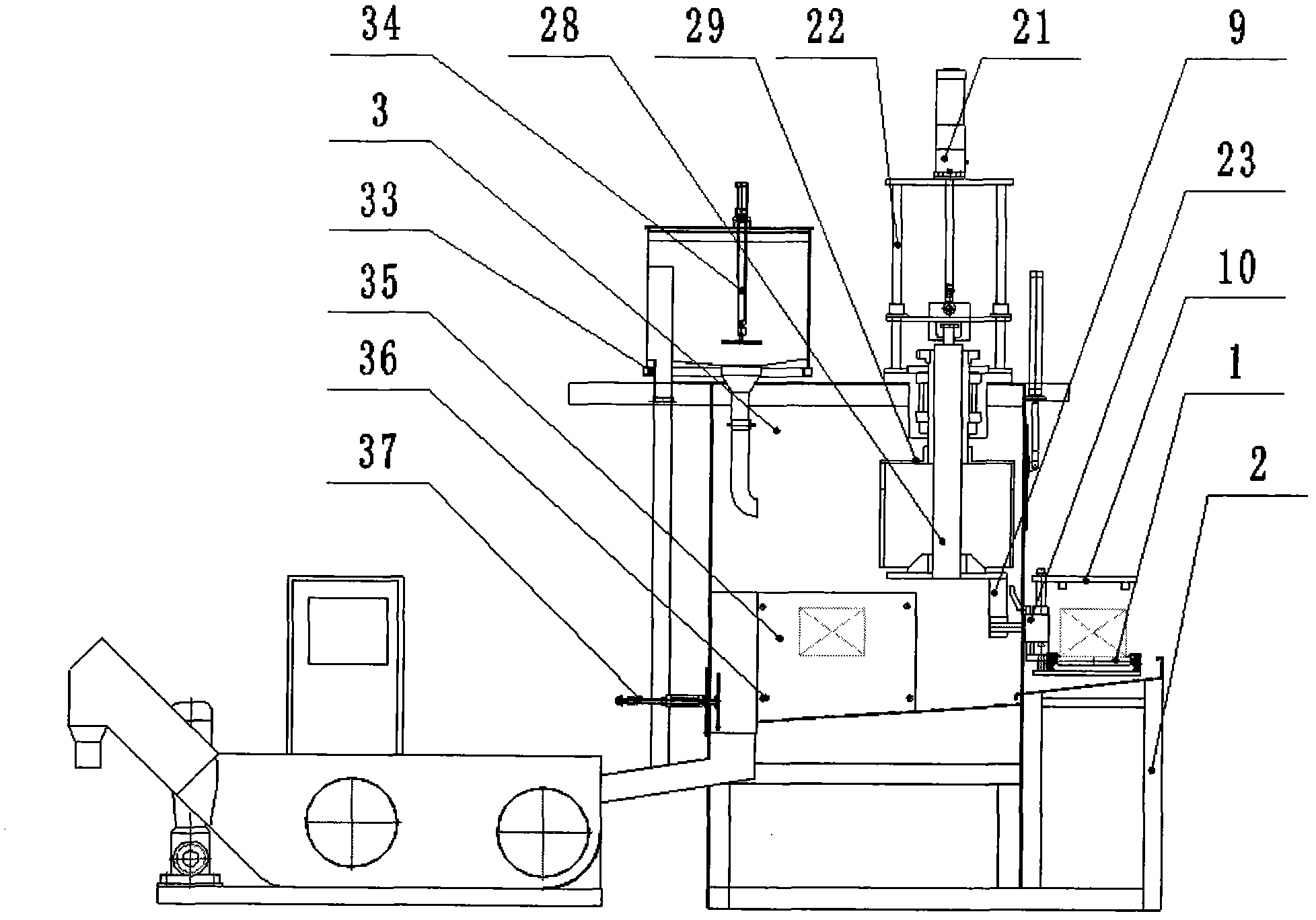

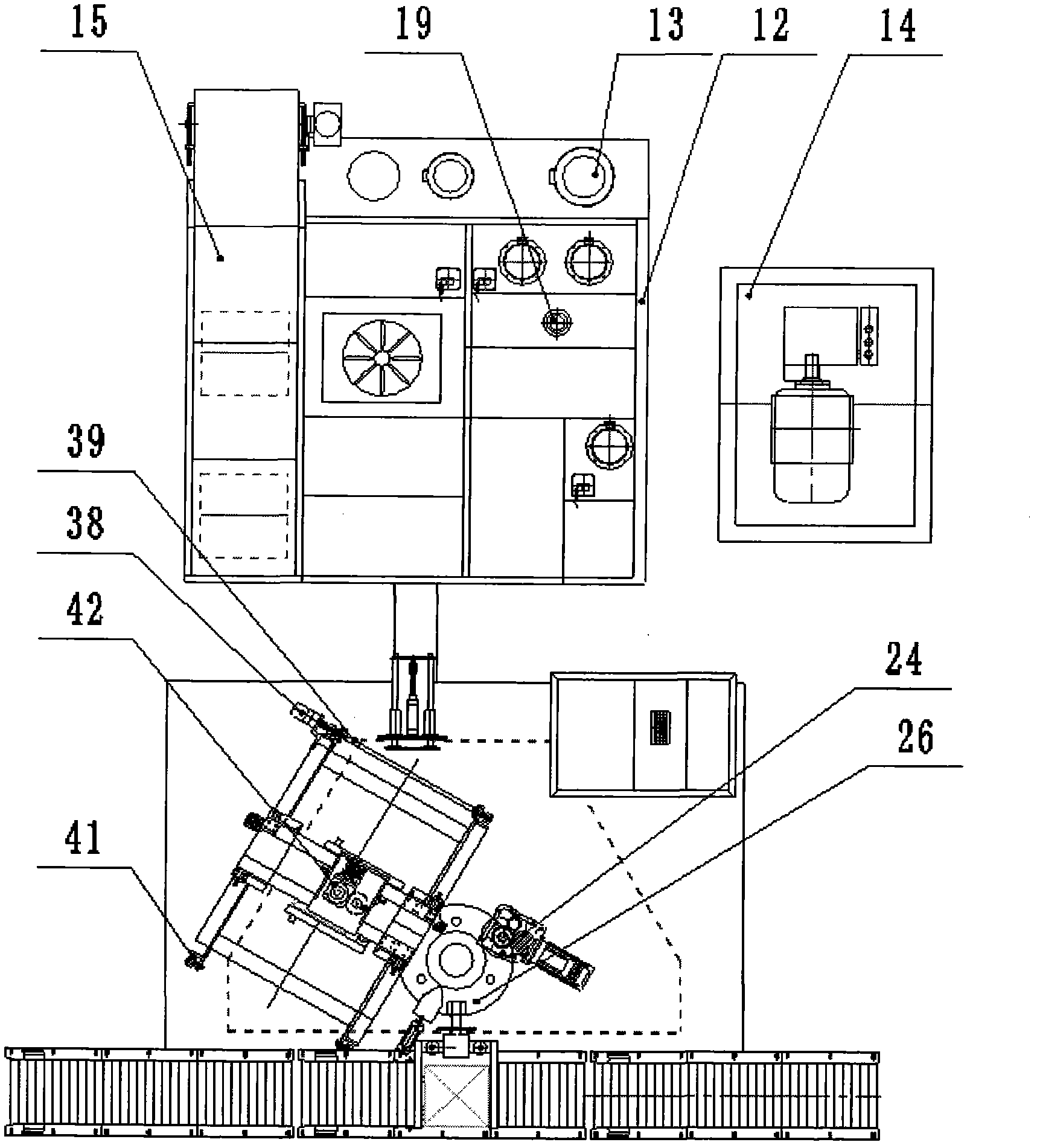

[0011] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0012] A jacking rotary CNC high-pressure cleaning machine is composed of a studio (3) composed of three stations, the three stations are set as a manual loading and unloading station (20), a flip surge + CNC high-pressure cleaning station (11 ) and scanning water blowing station (17). The workpiece is placed on the fixture (10) which can be stepped and rotated. After the fixture is lifted, the workpiece can be pressed tightly, and all processes can be automatically completed after one-time loading.

[0013] Rotary driving mechanism (7) and pneumatic lifting mechanism (8) are set, by lifting cylinder (21), lifting guide rod (22), clamp (10), clamp pressing device (23), rotating motor (24), gear ( 25), rotary positioning device (26), bearing block (27), rotating shaft (28), water retaining cylinder (29), etc. are formed. The lifting cylinder (21) lifts the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com