Automatic circulation screen filter device for blow-molding melt

An automatic circulation and net filtration technology, which is applied in the field of filtration devices of plastic machinery, can solve the problems of increased processing difficulty, waste of filter nets, and increased costs, and achieve the effects of improving production efficiency, saving time, and reducing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

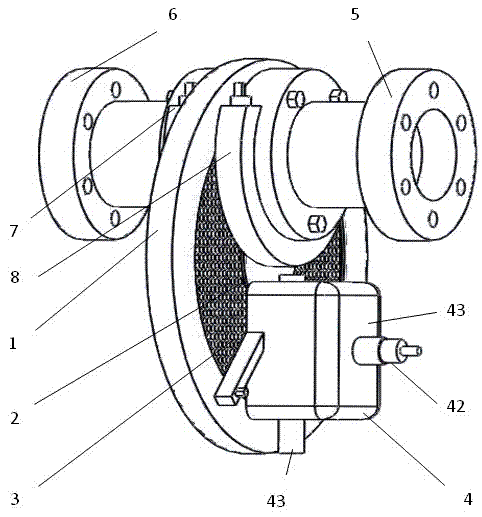

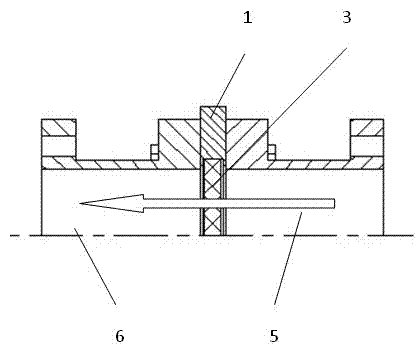

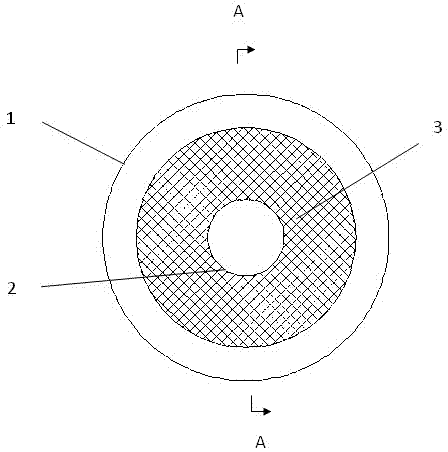

[0021] like figure 1 , figure 2 , image 3 Shown, the present invention comprises outer filter disc 1, inner filter disc 2, filter screen 3, enters melt chamber 5, goes out melt chamber 6, two cooling water pipes 7,8 and cleaning device 4; Outer filter disc 1 and the inner filter disc 2 are equipped with a filter screen 3, the melt inlet cavity 5 and the melt outlet cavity 6 are arranged on both sides of the filter mesh ring, the cleaning device 4 is arranged on one side of the filter mesh ring, two cooling water pipes 7 and 8 are respectively installed on the flange cylindrical surface close to the filter screen 3 in the melt chamber 5 and the melt chamber 6. In the figure, the two cooling water pipes surround the lower half of the flange cylindrical surface and exceed the flange cylindrical surface 1 / 2 circle, the cooling water solidifies the melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com