Jacket unit, jacket tank and manufacture method of jacket tank

A manufacturing method and jacket technology, applied to tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of reducing the thickness of the tank body plate 4, the high material cost of the jacket tank 1, and the lack of reinforcement of the tank body 2, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

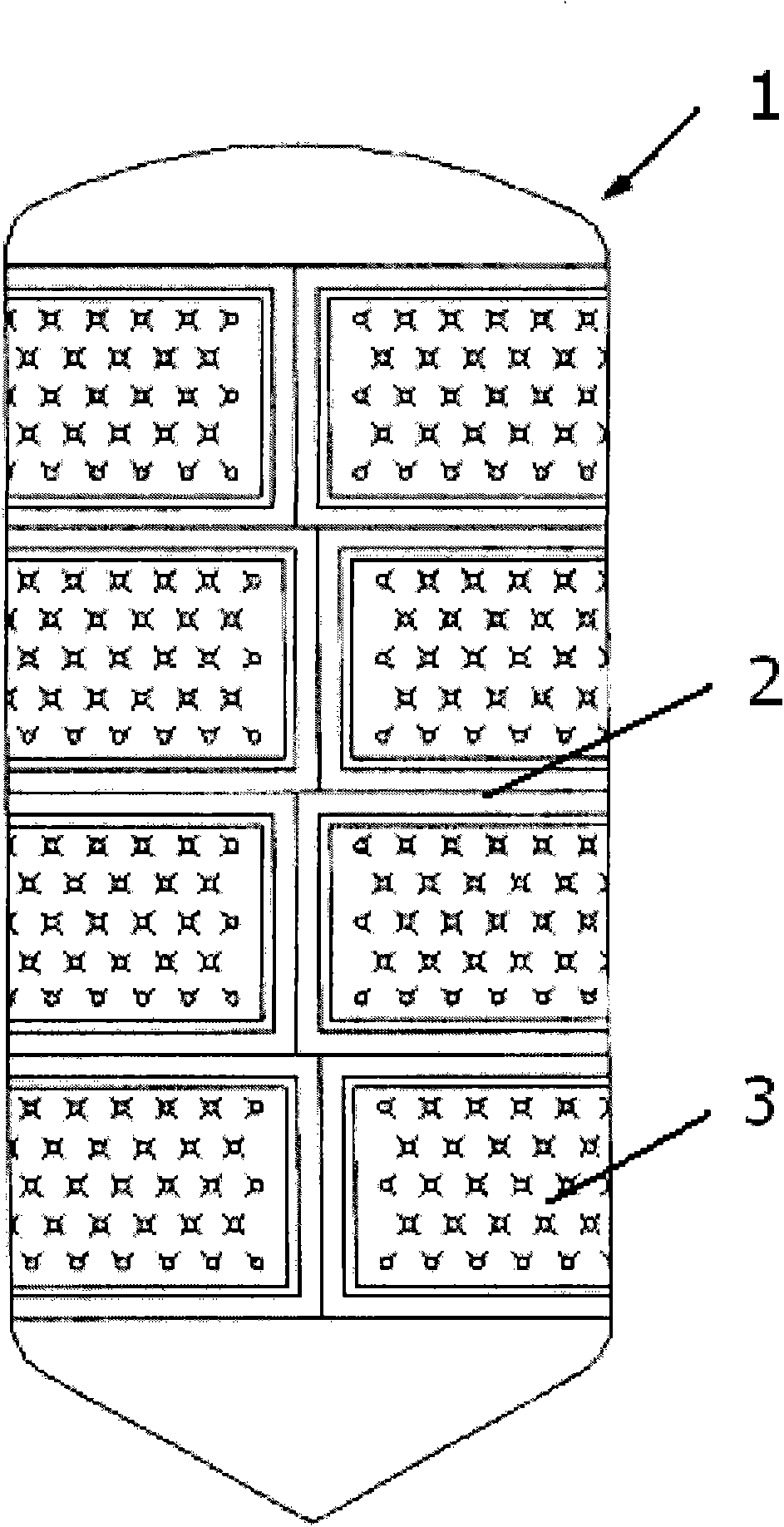

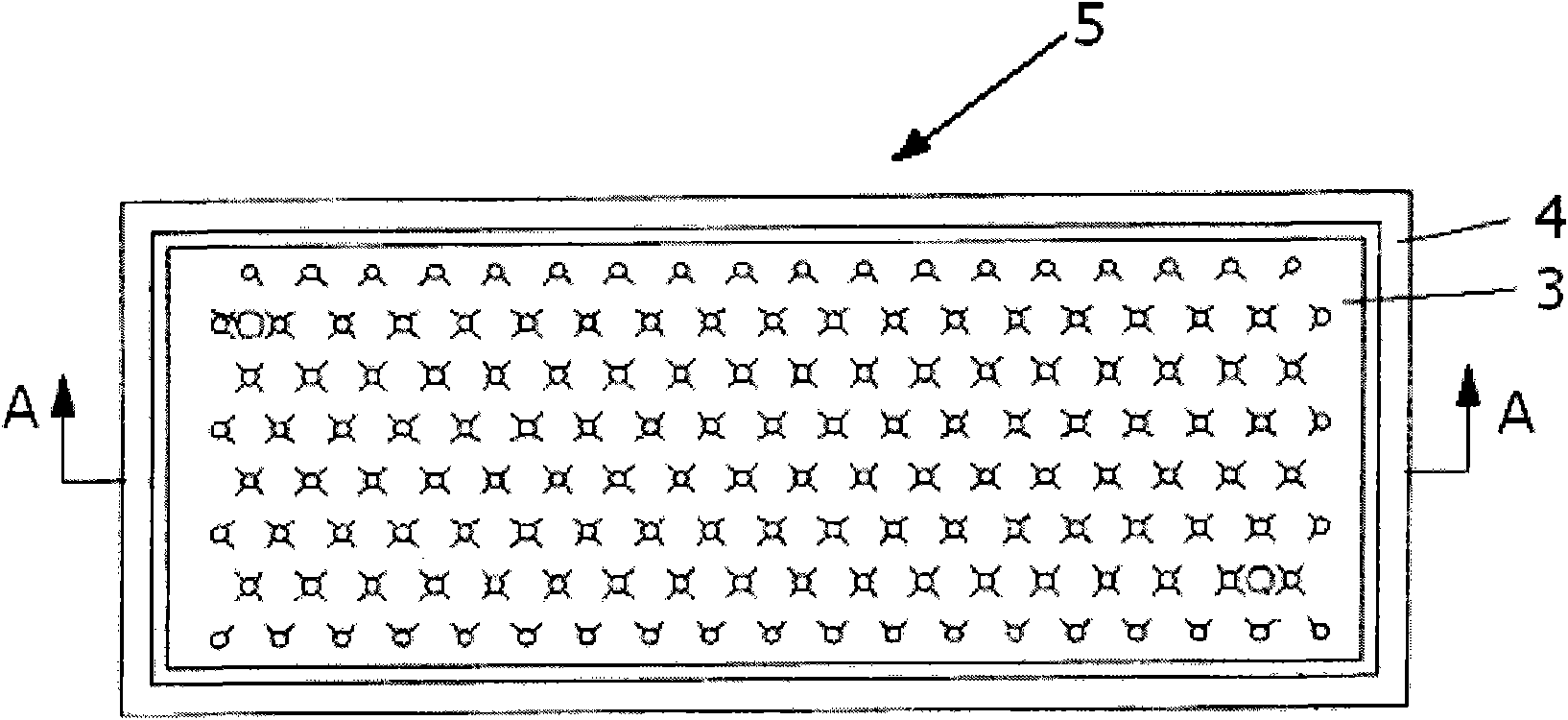

[0025] Figure 4 The overall structure of the honeycomb jacketed tank 11 according to one embodiment of the present invention is schematically shown. Figure 5a with 5b is shown for forming Figure 4 The specific structure of the individual jacketed unit 15 of the jacketed tank 11 is shown.

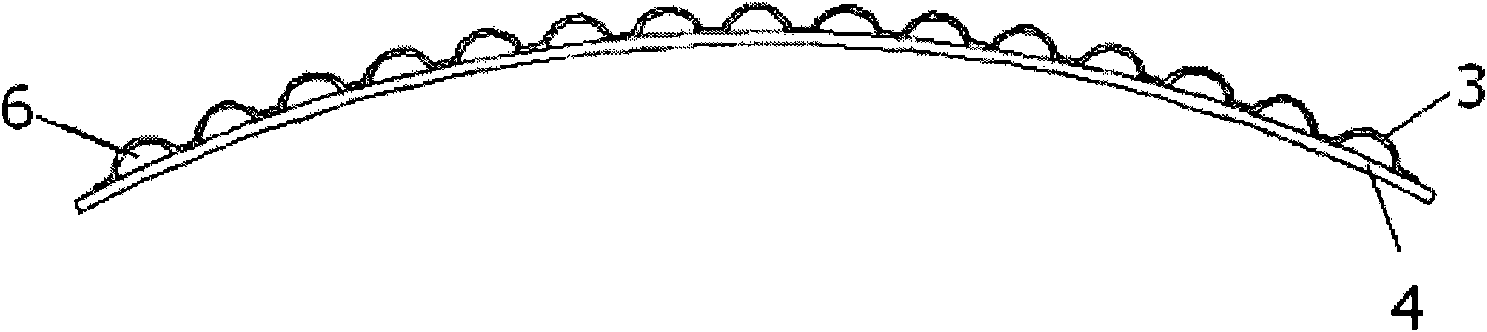

[0026] Such as Figure 5a with 5b As shown, the jacket unit 15 consists of a thinner jacket plate 13 and a thicker tank plate 14 . Wherein, when making the jacket unit, firstly, the jacket plate 13 with the same shape and size as the tank plate 14 is stacked on the tank plate 14, and the two plates are processed on the sides of the jacket plate 13 and the tank plate 14. Spot weld to align the two plates. Then the peripheral edge of the jacket plate 13 and the peripheral edge of the tank body plate 14 are fixedly connected together in a liquid-tight manner by laser welding, and the middle of the jacket plate 13 is connected by a plurality of evenly distributed welding spots formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com