Coated member and its manufacturing method

A manufacturing method and technology of coating parts, applied in the field of coating parts with black appearance and its production, capable of solving problems such as target poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

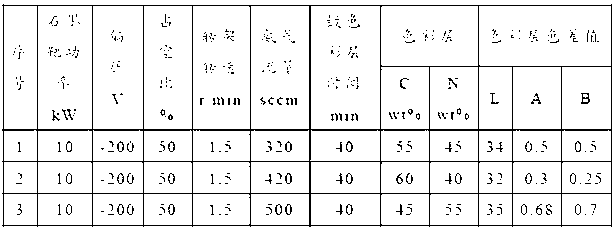

Examples

Embodiment Construction

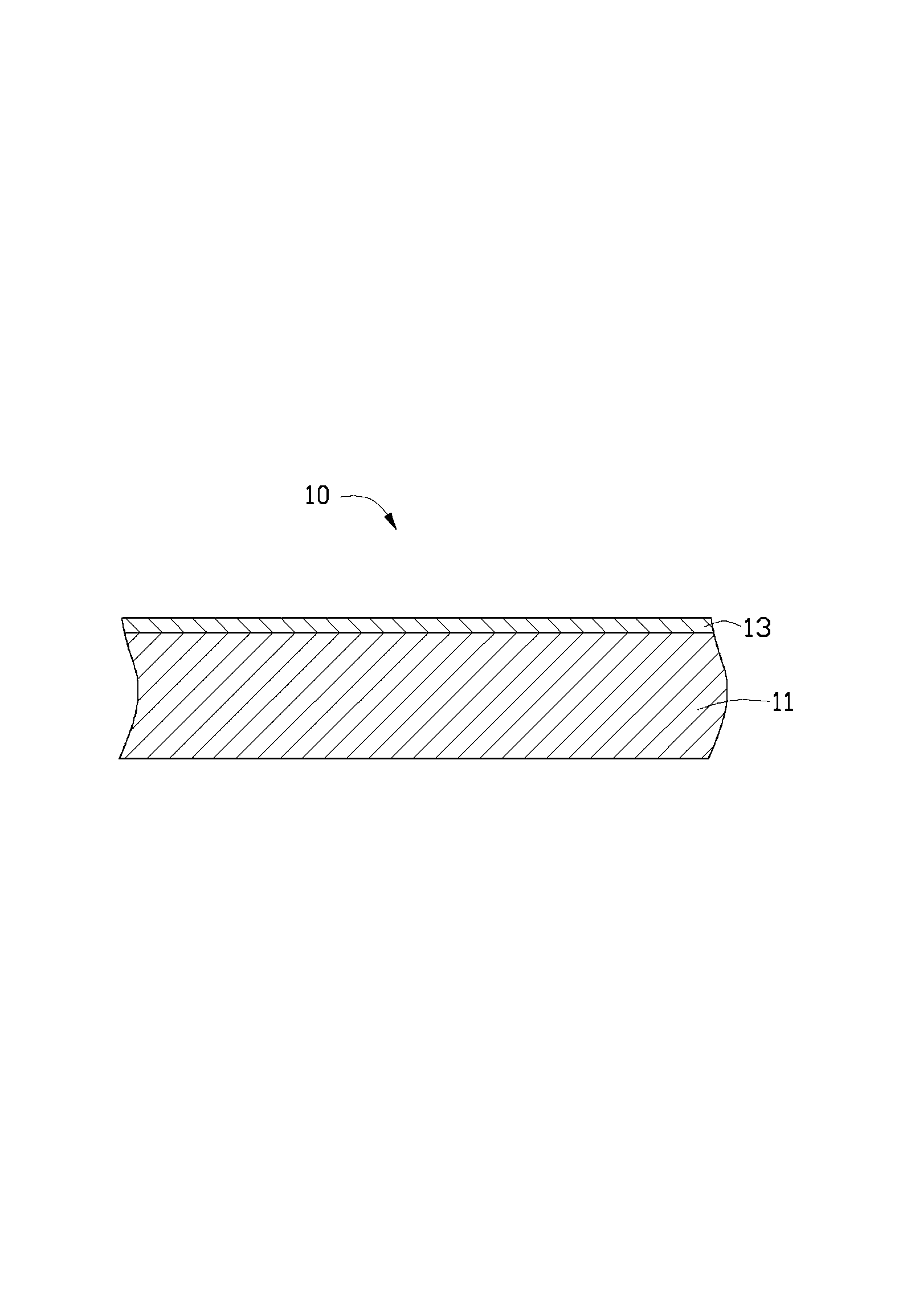

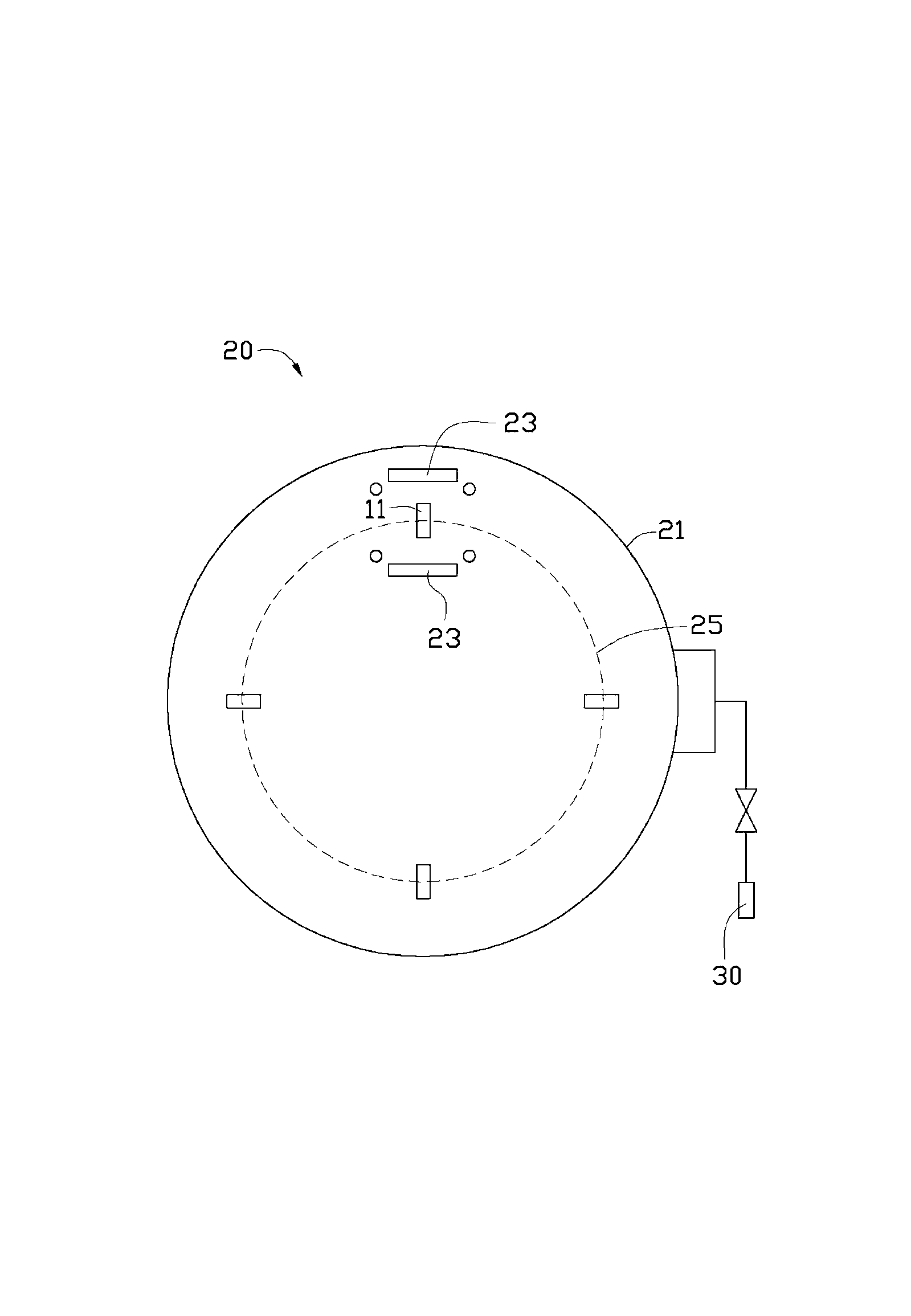

[0016] see figure 1 , the coating member 10 of the preferred embodiment of the present invention includes a base 11 and a color layer 13 formed on the base 11 .

[0017] The material of the base body 11 can be one of metal, glass, ceramic and plastic.

[0018] The color layer 13 is C x N layers, where 2 / 3≦x≦3. The color layer 13 visually presents black to the naked eye, and its chromaticity area in the CIE LAB color system has L* coordinates between 32 and 35, a* coordinates between 0.6 and 1, and b* coordinates between 0.8 and 1. between. The color layer 13 has a thickness of 500-700 μm. The color layer 13 is formed by magnetron sputtering.

[0019] The coating part 10 can be a casing of electronic devices such as notebook computers and personal digital assistants, or a decorative component of other products.

[0020] The manufacturing method of above-mentioned coating member 10, comprises the following steps:

[0021] A substrate 11 is provided. The material of the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap