Soft direct-connection structure of diesel engine pumping unit

A diesel engine and water pump technology, applied in elastic couplings, machines/engines, pumps, etc., can solve problems such as broken shaft or broken teeth, diesel engine or water pump damage, and the unit cannot work normally, so as to reduce the probability of broken teeth, The effect of reducing installation accuracy requirements and efficiently transmitting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

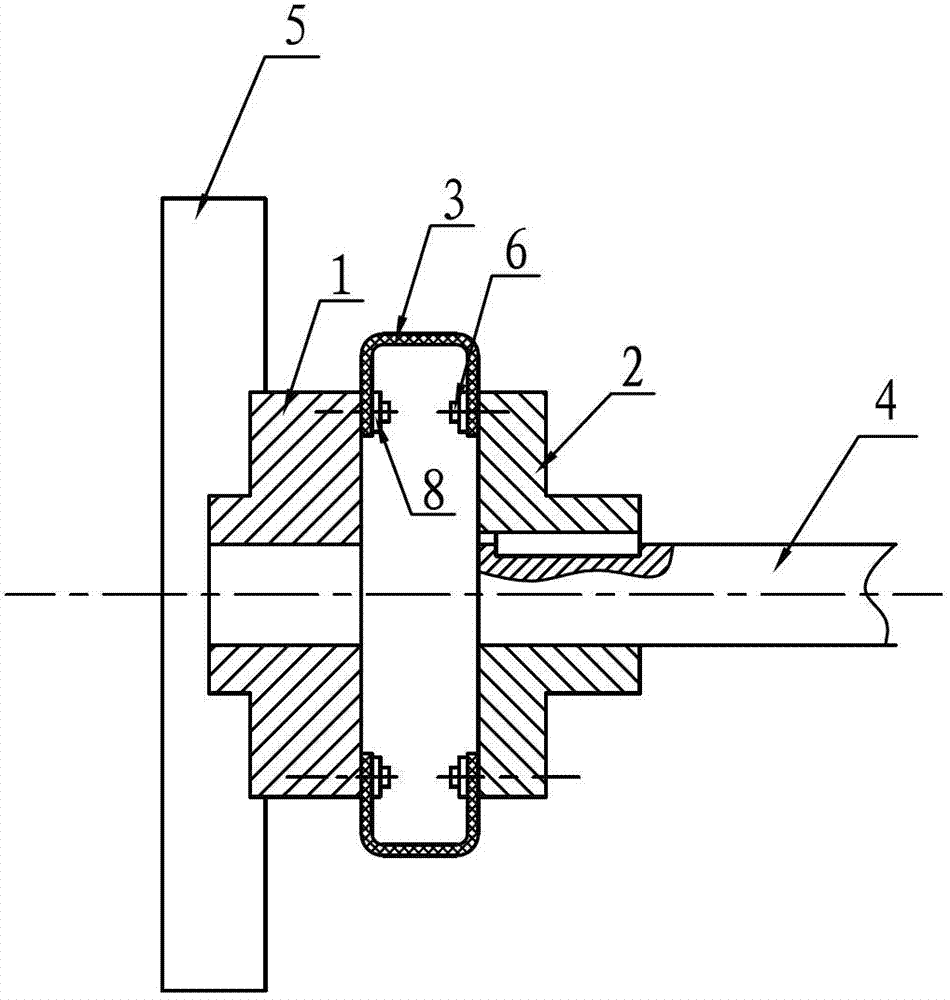

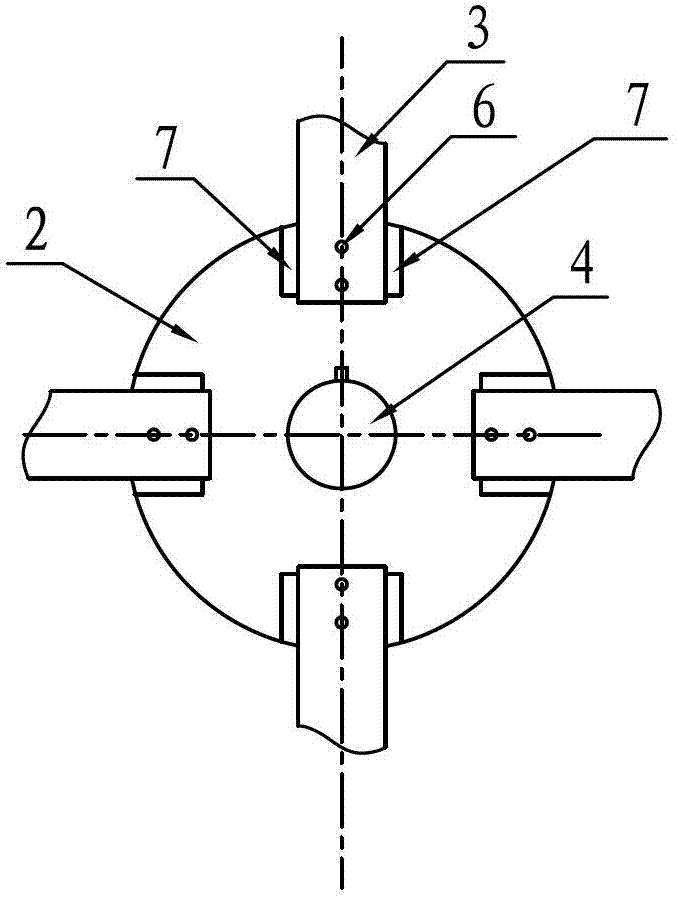

[0021] A soft direct-connection structure of a diesel engine water pump unit, such as figure 1 , figure 2 As shown, it includes the power output disk 1 of the diesel engine, the power input disk 2, the elastic belt segment 3, the water pump main shaft 4, the diesel engine flywheel 5 and the screw 6, the power output disk 1 is connected with the diesel engine flywheel 5 in a fixed phase, and the power input disk 2 is connected with the The water pump main shaft 4 is fixedly connected, and four elastic belt sections 3 are evenly fixed along the circumference between the power output disk 1 and the power input disk 2, and one end of each elastic belt section 3 is fixed on the On the power output disk 1, the other end is fixedly installed on the power input disk 2 through screws 6 and gaskets, and the two sides of the part where the elastic belt section 3 is installed on the power output disk 1 and the power input disk 2 are provided with limit strips 7, elastic The belt segment...

Embodiment 2

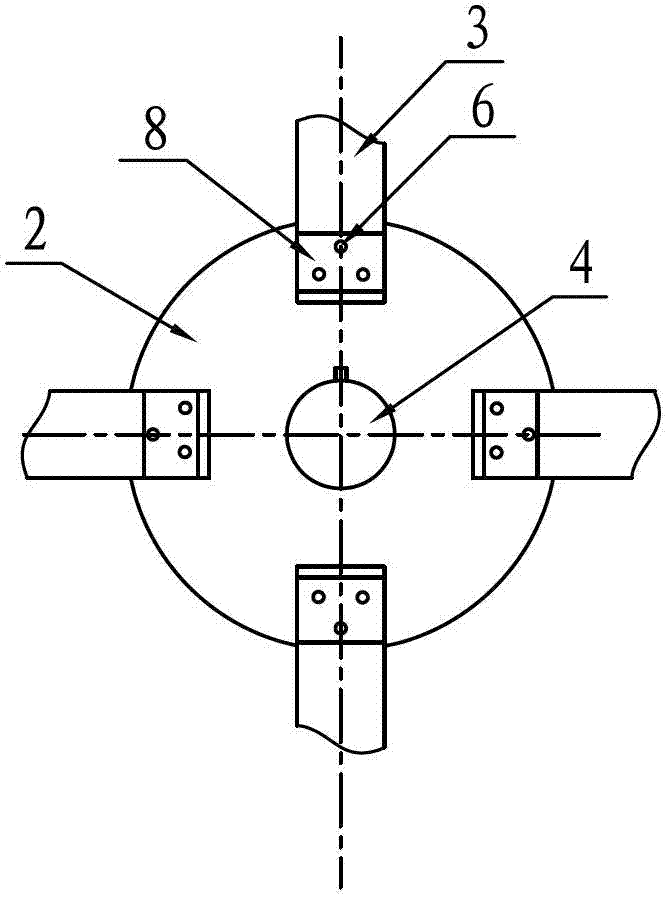

[0023] A soft direct-connection structure of a diesel engine water pump unit, such as figure 1 , image 3 As shown, it includes the power output disk 1 of the diesel engine, the power input disk 2, the elastic belt segment 3, the water pump main shaft 4, the diesel engine flywheel 5, the screw 6 and the pressure plate 8, the power output disk 1 is fixedly connected with the diesel engine flywheel 5, and the power input The disk 2 is fixedly connected with the water pump main shaft 4, and four elastic belt sections 3 are evenly fixed along the circumferential direction between the power output disk 1 and the power input disk 2, and one end of each elastic belt section 3 passes through a pressure plate 8 and three screws 6 is fixed on the power output disk 1, and the other end is fixedly installed on the power input disk 2 through the pressure plate 8 and three screws 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com