Engine correction system for correcting controlled variables of actuator

An engine and actuator technology, applied in the direction of machine/engine, engine control, electrical control, etc., can solve the problems of performance parameter interference, performance parameter deviation from the optimal target value, parameter calibration parameter calibration accuracy decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

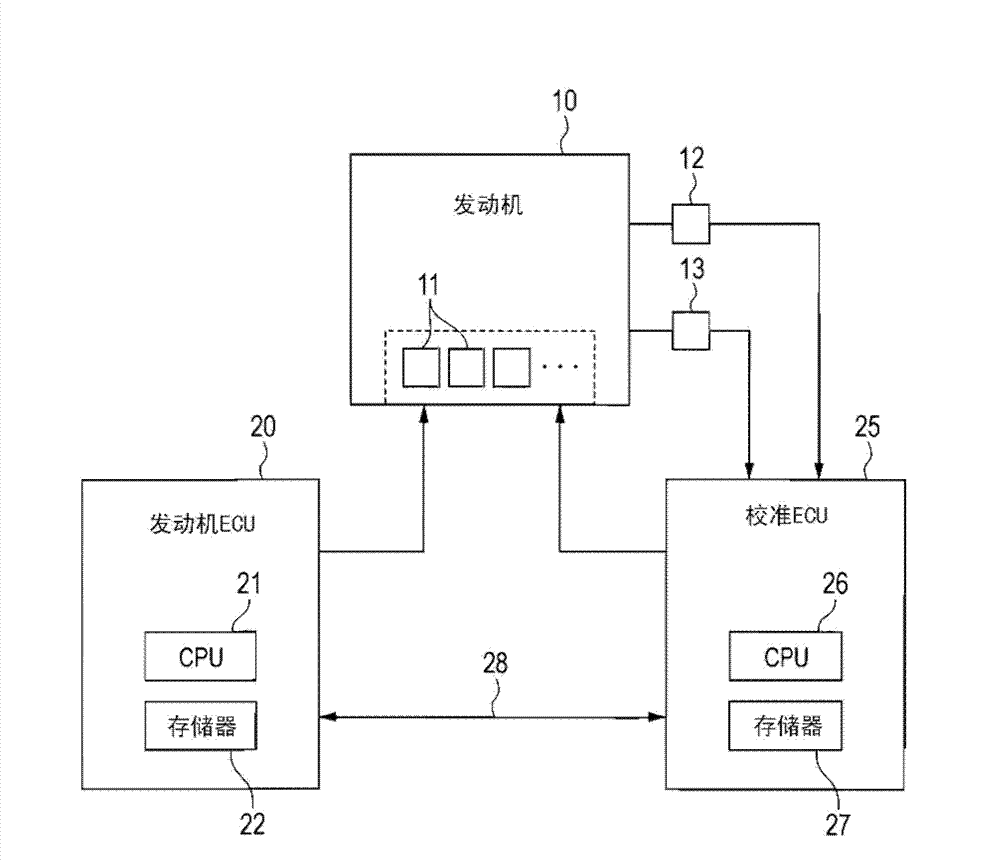

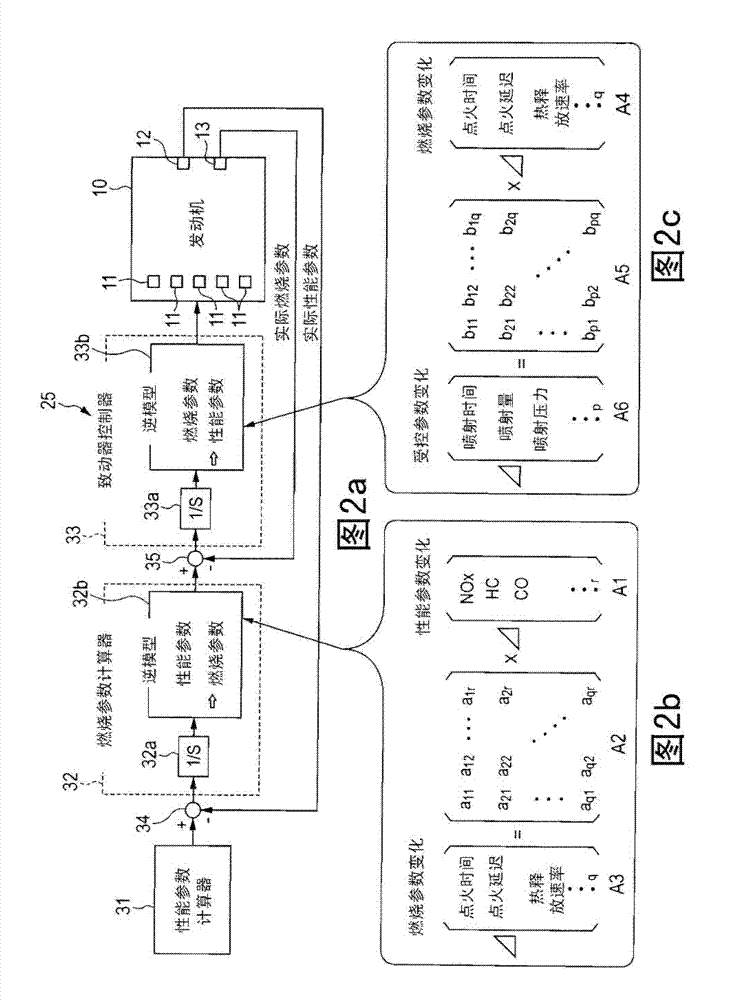

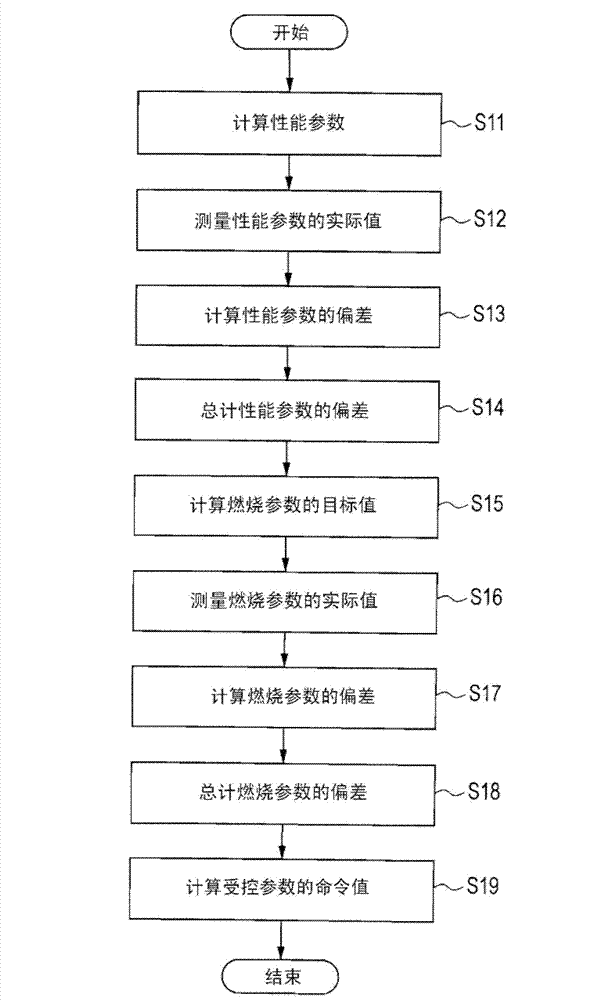

[0021] Referring to the drawings, in which like reference numerals denote like parts throughout the several views, in particular figure 1 (a), shows the engine calibration system according to the first embodiment, which is designed to realize the calibration of different types of control tasks, to obtain calibration values (ie, optimal values) and store them in the engine In the memory of the ECU (Electronic Control Unit) 20 .

[0022] The engine calibration system is also used as an engine control system of the internal combustion engine 10 installed in a motor vehicle. The following discussion will refer to a self-ignition diesel engine as an example in which fuel is injected under high pressure into four cylinders #1 to #4. The engine 10 has installed therein an actuator 11 for controlling the operation of the engine 10 at a desired operating condition. The actuator 11 installed in the fuel system is, for example, a fuel injector that injects fuel to the engine 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com