Online calibration method of in-situ type laser gas analyzer

A technology of laser gas and calibration method, applied in the direction of color/spectral characteristic measurement, etc., can solve the tediousness, increase the operation and maintenance cost of the in-situ laser gas analyzer, and the calibration, calibration and verification method of the in-situ laser gas analyzer Complex problems, to achieve the effect of reducing operation and maintenance costs and simplifying the calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

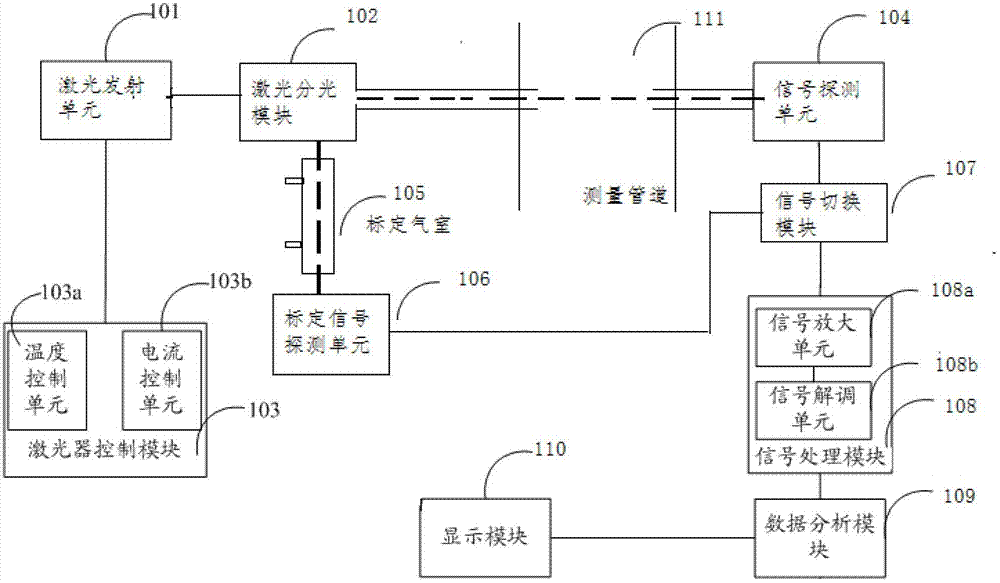

[0046] figure 1 A schematic diagram of the structure of the in-situ laser gas analyzer online calibration device provided by the embodiment of the present invention, the device includes:

[0047] Laser emission unit 101, laser spectroscopic module 102, laser control module 103, signal processing detection unit 104, calibration gas chamber 105, calibration signal detection unit 106, signal switching module 107, signal processing module 108, data analysis module 109, display unit 110 And measuring pipeline 111.

[0048] The laser control module 103 is connected to the laser emitting unit 101 for driving the laser emitting unit 101 to emit laser light with a specific wavelength.

[0049] The laser emitting unit 101 may be a tunable diode laser, specifically: a semiconductor distributed feedback laser or a semiconductor vertical cavity surface emitting laser.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap