Computer Online Debugging Method of Grid-connected Inverter

A debugging method and inverter technology, applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., can solve the problems of unsynchronized comparison, uncontrollable safety, and difficulty in inverter debugging, so as to achieve fast debugging and improve safety Sexual, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

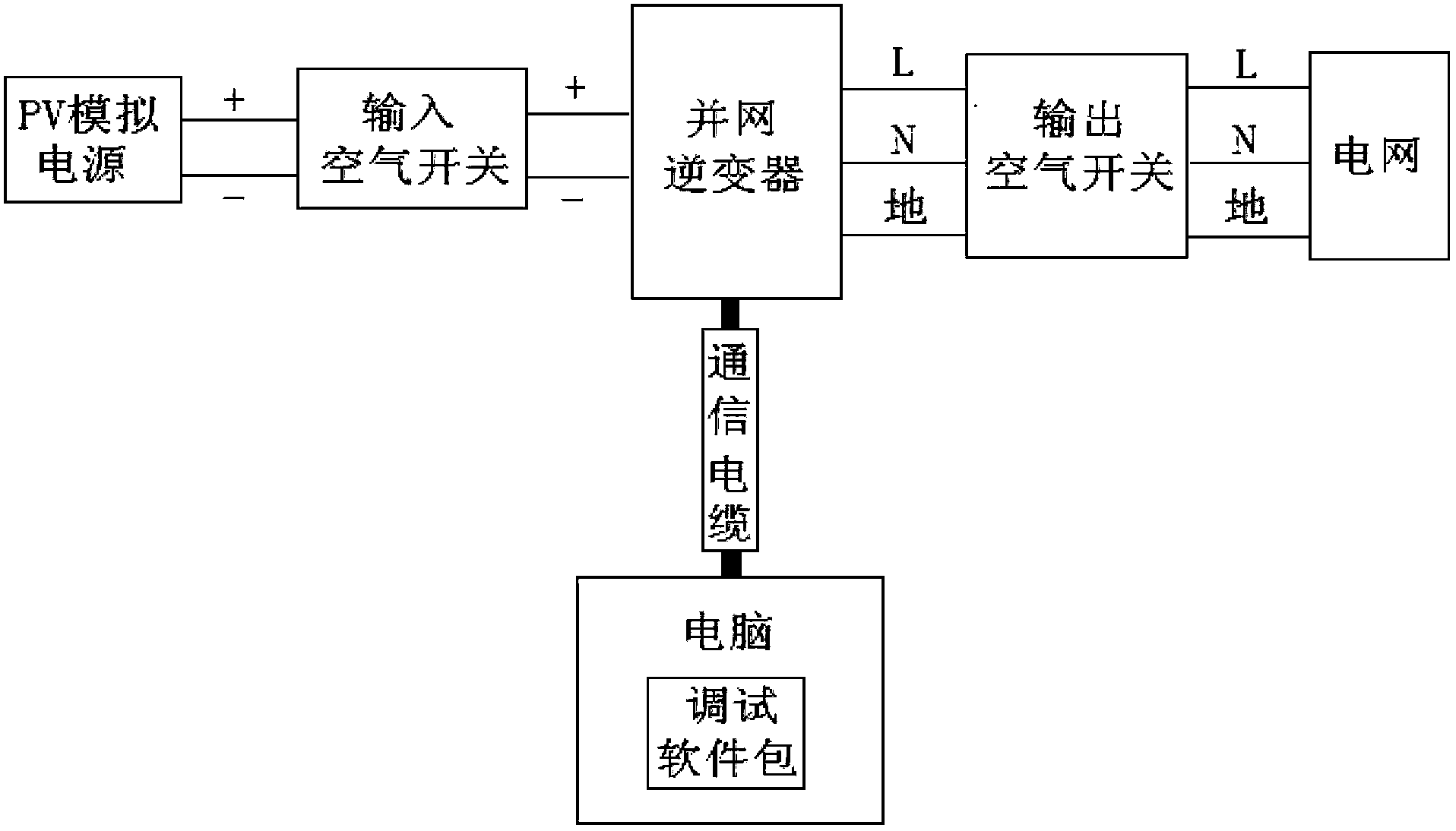

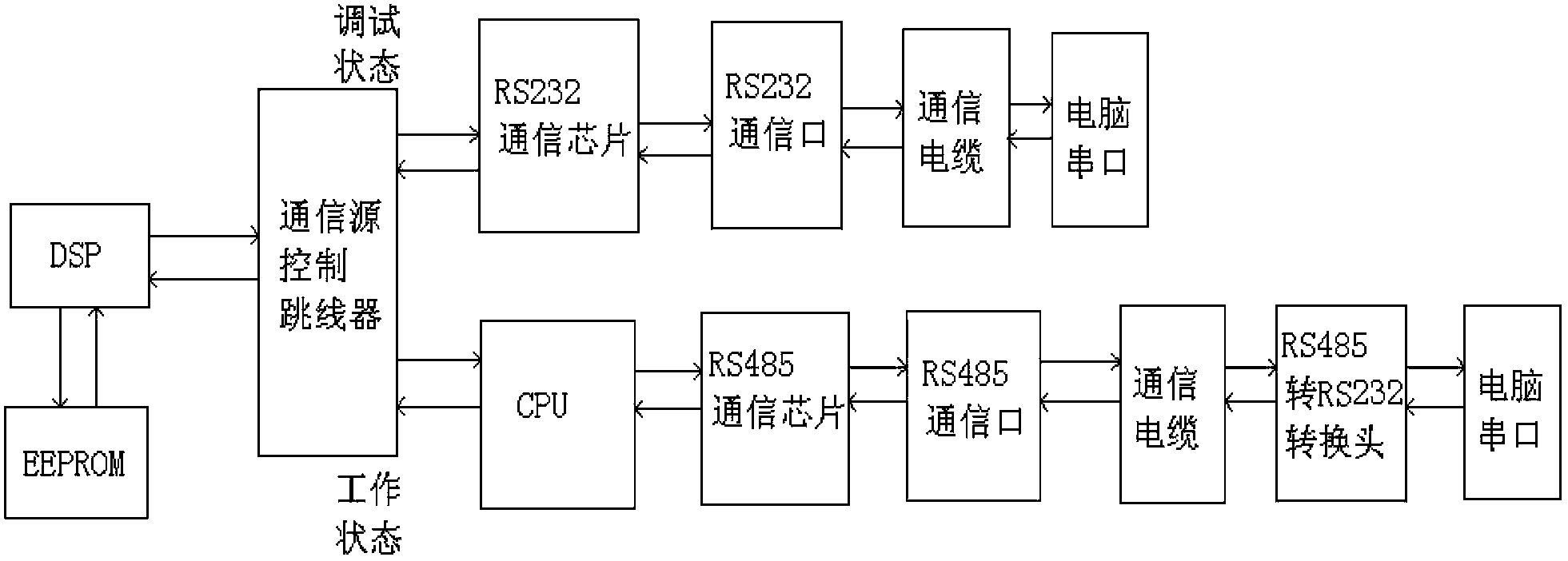

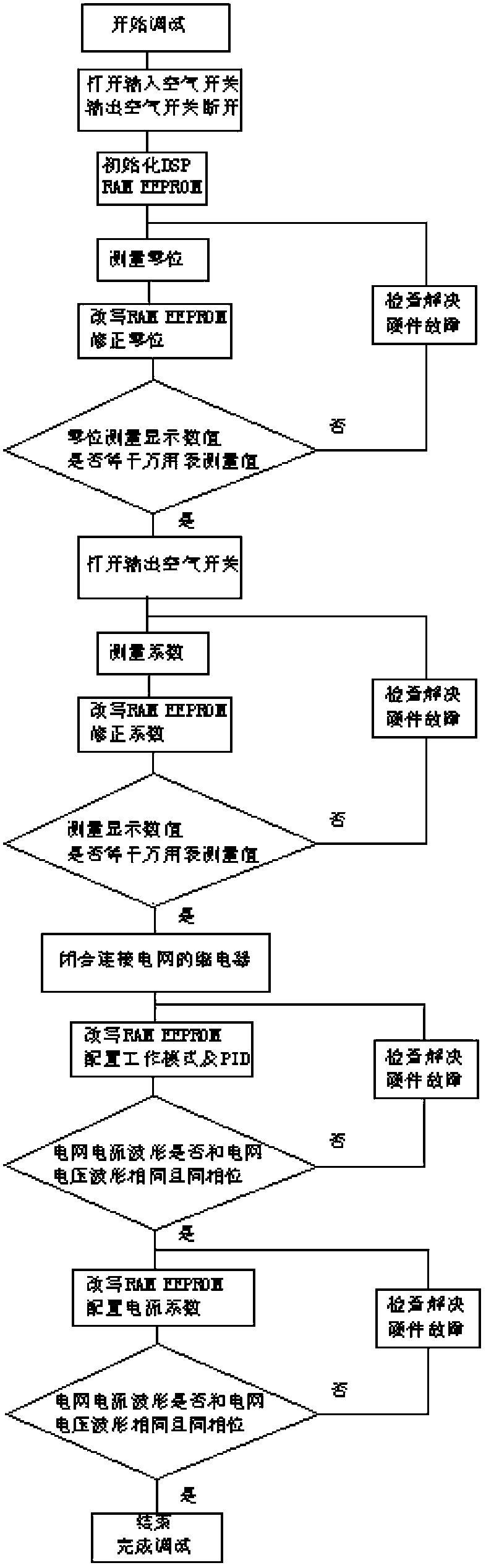

[0038] This embodiment is an example of applying the present invention to a 5000W grid-connected inverter system. Such as figure 1 , 2 and image 3 As shown, the technical steps are as follows:

[0039] Step 1: Zero correction and configuration. Turn on the input air switch and close the output air switch. At this time, since the grid-connected inverter is in the idle state, observe the display values of each physical quantity by running the RS232 debugging software in the computer. The normal value should be: grid voltage NetUac=0± 2 volts, grid current NetIac=0.0±0.2A, module voltage IpmUac=0±2V, module current IpmIac=0.0±0.4A, module DC IpmJdc=0.000±0.004A, battery current PvIdc=0.1±0.1A.

[0040] 1. If the displayed value of each physical quantity of the debugging software is within the normal value range, then complete the zero point correction and configuration;

[0041] 2. If the displayed value of each physical quantity of the debugging software is not within th...

Embodiment 2

[0057] This embodiment is an example of applying the present invention to a 2000W grid-connected inverter system. Such as figure 1 , 2 and image 3 As shown, the technical steps are as follows:

[0058] The debugging method of step 1 to step 3 is the same as the corresponding debugging method of embodiment 1; for step 4, the power is set to the rated power of 2000W, and the other debugging methods are the same; step 5 is also the same as the debugging method of step 5 of embodiment 1.

[0059] For grid-connected inverters of other power systems, as long as the power is set to the corresponding rated power, the online debugging method of the present invention is also applicable.

[0060] The online debugging method of the present invention can be applied to the debugging of most grid-connected inverter systems based on DSP / CPU.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com