Spent fuel storage framework of nuclear power plant

A storage grid and spent fuel technology, applied in nuclear power generation, reactor fuel elements, nuclear engineering, etc., can solve the problems of unfavorable fuel assembly loading and unloading, unfavorable fuel assembly operation, low storage capacity, etc., to achieve easy modular manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

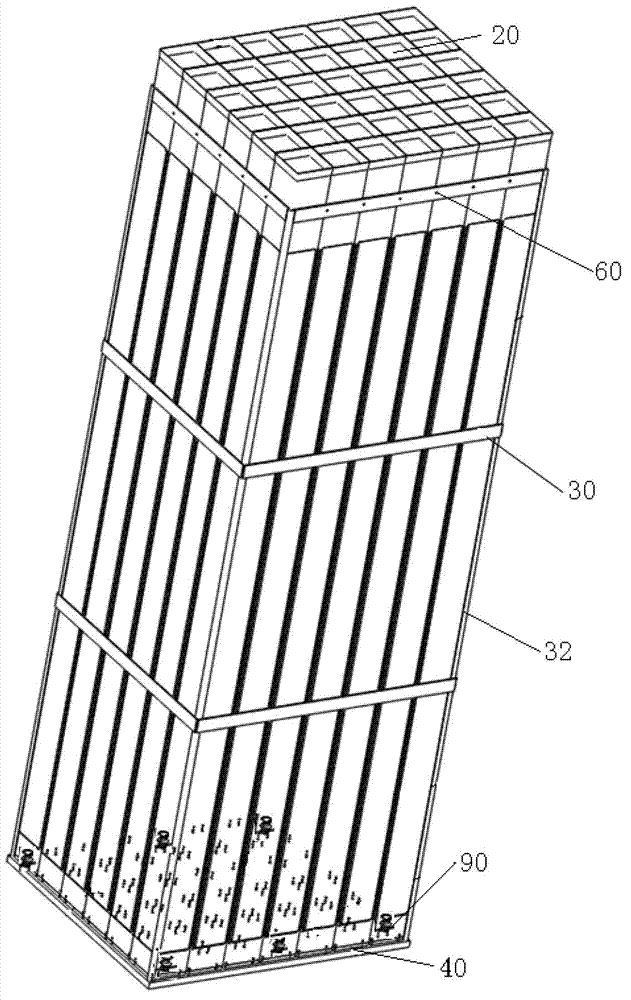

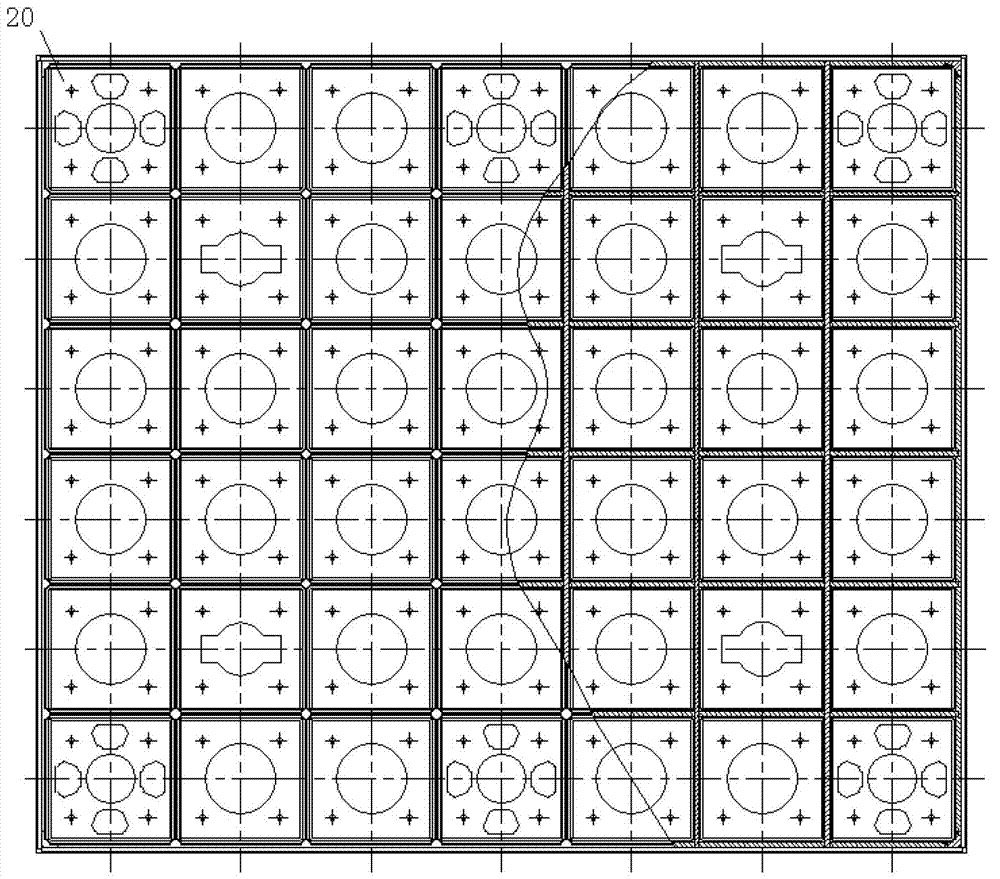

[0027] see figure 1 with figure 2 , The nuclear power plant spent fuel storage grid of the present invention includes a storage chamber 20 , a strip-type fixing structure, a grid bottom plate 40 and a leg assembly 90 .

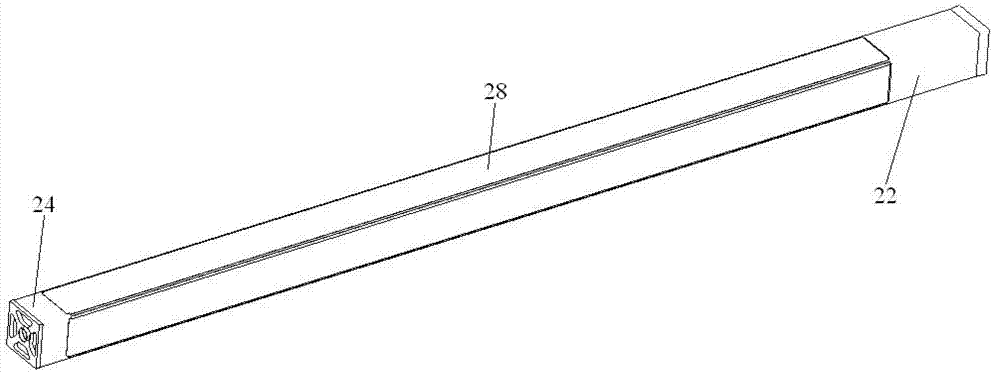

[0028] Please also see Figure 3 to Figure 4 , the storage chamber 20 is an independent storage chamber unit, and each independent storage chamber unit includes a sleeve 22 , a storage chamber base 24 , a neutron absorber and a cladding plate 28 . The sleeve 22 is a square sleeve, and the neutron absorber is fixed on the outer wall of the sleeve 22 through a cladding plate 28, and the whole sleeve 22 is fixed on the storage chamber base 24 which is also a square shape by welding, thereby forming an independent Storage compartment unit. A larger threaded hole 240 is opened in the center of the base 24 of the storage chamber, and four smaller connecting holes 241 and four trapezoidal water holes 242 are opened around it.

[0029] Connecting holes (not shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com