Rolling bearing

A technology of rolling bearings and retained austenite, which is applied in the field of rolling bearings, can solve problems such as inability to perform at the same time, and achieve the effects of extending bearing life, reducing costs, and inhibiting brittle peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

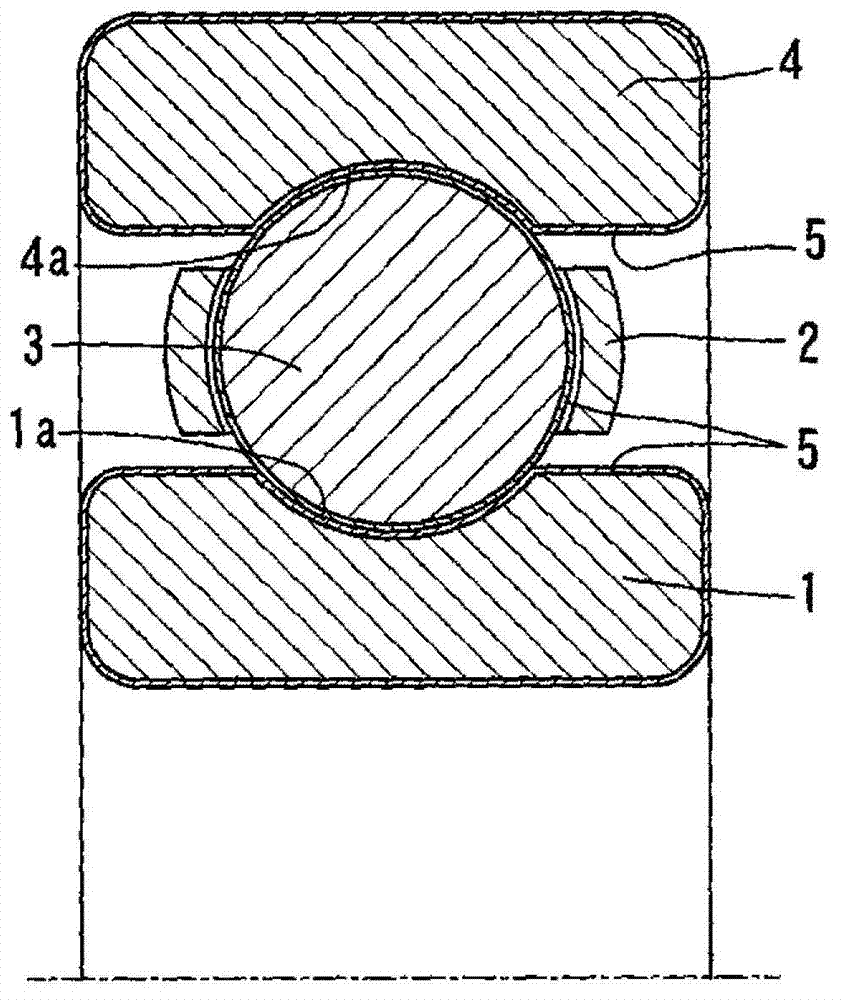

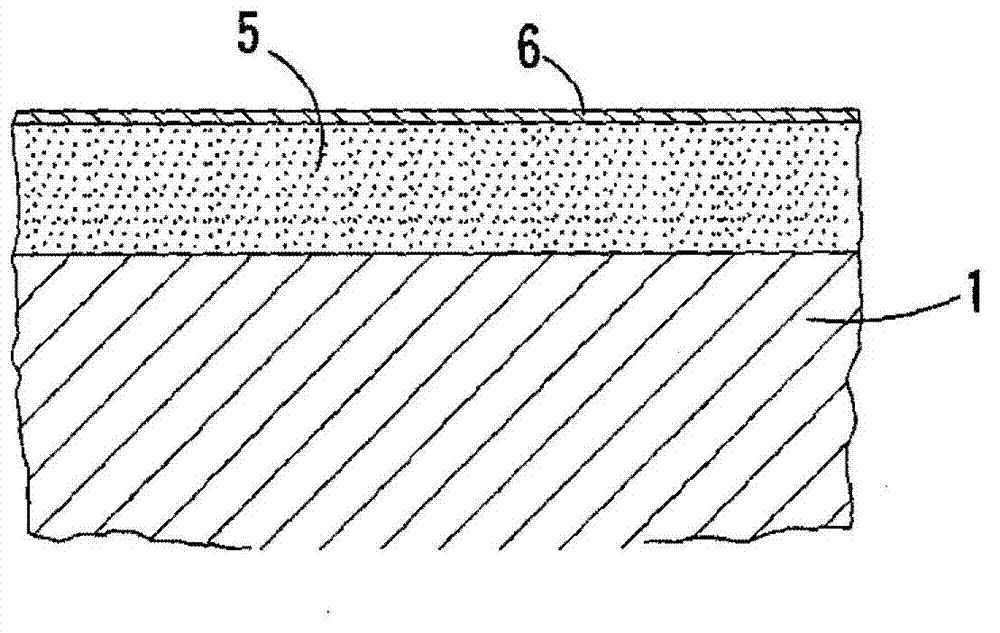

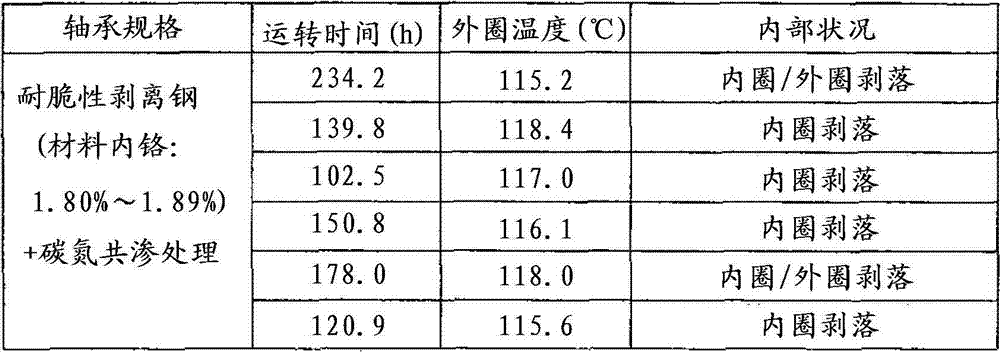

[0038] The bearing steel (hereinafter referred to as "brittle peeling resistance steel") according to the present invention is used. figure 1 The deep groove ball bearing of the shape shown, and the aging resistance test of the bearing was carried out. This embrittlement-resistant peeling steel is a steel containing 1.80% to 1.89% of chromium in a weight ratio, and by subjecting the embrittlement-resistant peeling steel to the aforementioned carbonitriding treatment, a retained austenite region 5 is formed in the surface layer portion.

[0039] Assuming the environment in which the bearings used in the continuously variable transmission of a car are located, the CVTF lubricant (CVTF) is mixed with fine steel powder as a foreign matter, and the lubricant is mixed with 0.15g of the foreign matter per liter of the lubricant. The aging resistance test was performed. The radial load loaded by the bearing is set to 8300N (the axial load is 0N), the rotation speed of the inner ring is s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap