A method of manufacturing a lens for providing an optical display

A lens and optical technology, applied in optics, optical components, optical components, etc., can solve problems such as cracking, material separation, and difficulty in trimming and cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

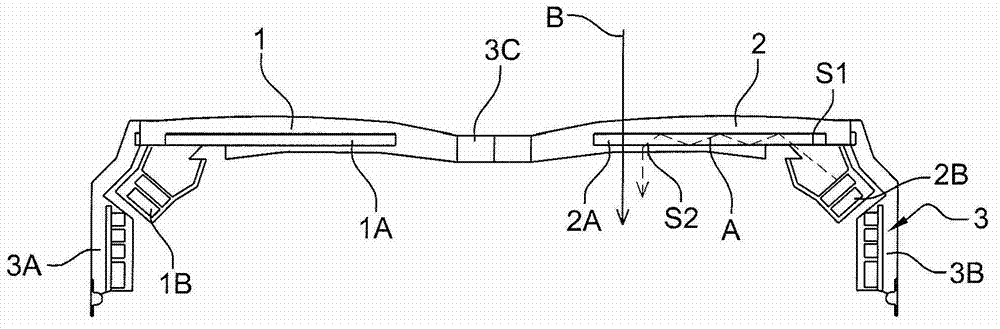

[0031] refer to figure 1 , the ophthalmic binocular display includes two lenses 1,2. Each lens includes a projection insert consisting of an optical imager 1A, 2A for shaping the beam from an electronic and optical system 1B, 2B that generates the beam based on an electronic signal, the optical system being a microscreen, Laser Diode or Light Emitting Diode type. The optical imager directs the light beam from the entering surface S 1 away from the surface S 2 directed to the wearer's eye so that the information content can be seen, as indicated by the dotted arrow A on the right lens. These lenses may allow see-through, the ambient viewport shown by arrow B on the right lens.

[0032] The lenses 1, 2 are mounted in a frame 3 for spectacles or lenses, which frame comprises two branches 3A, 3B and a nose pad 3C.

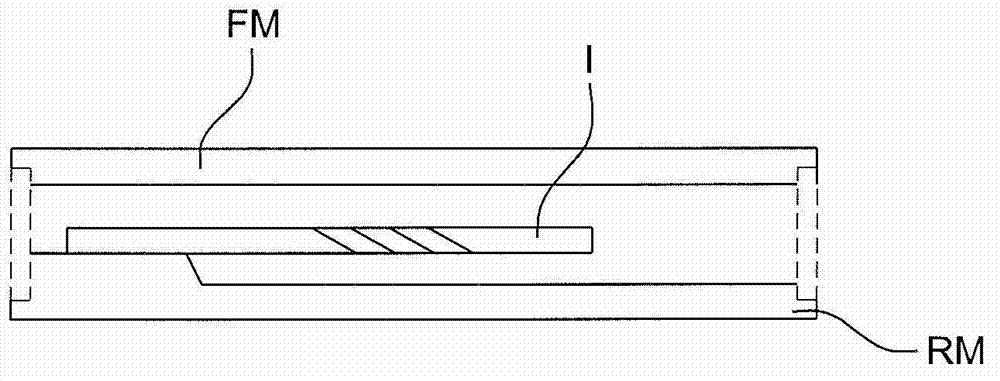

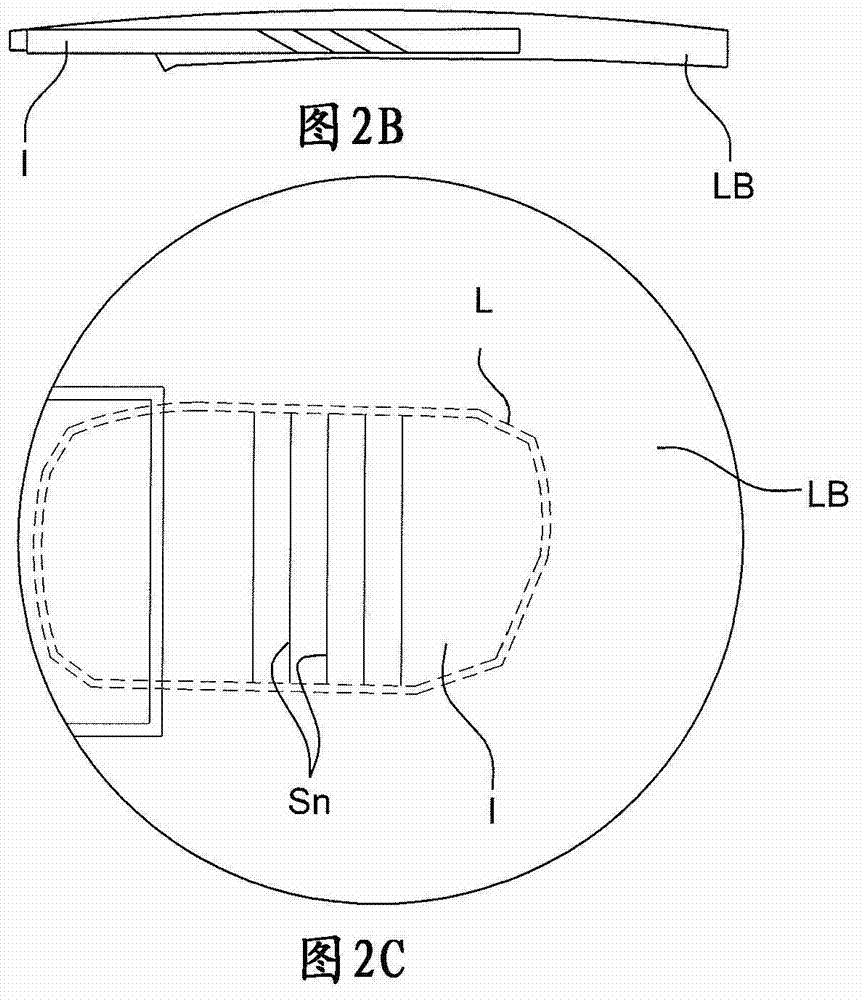

[0033] Figure 2A , 2B and 2C illustrate the method according to the first embodiment of the invention.

[0034] As described in patent document WO 2006 / 016086...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com