X-ray tube

An X-ray tube and X-ray technology, applied in the field of X-ray tubes, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

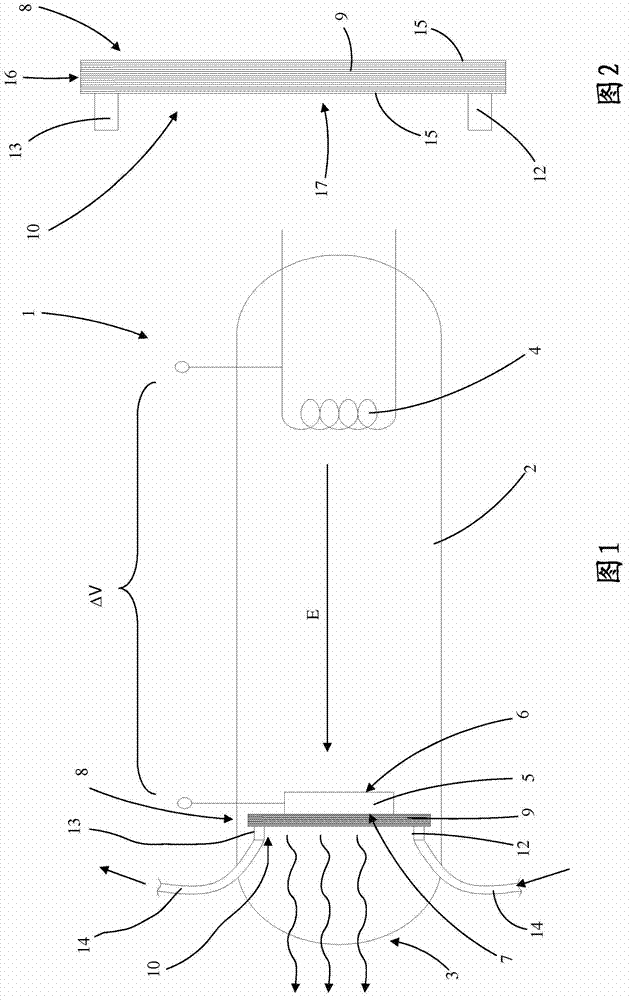

[0026] Referring to the drawings, reference numeral 1 generally denotes an X-ray tube manufactured according to the present invention.

[0027] Similar to prior art X-ray tubes, the X-ray tube according to the invention firstly comprises a closure element 2 which is preferably a glass bulb or the like. The closure element 2 also comprises an emitting part 3, by which the X-rays generated in the tube 1 can be sent towards the area where they are used, for example for X-ray inspection of wood pieces. Such as figure 1 As shown in , a cathode 4 and an anode 5 separated by a space are mounted inside the closure element 2 .

[0028] The cathode 4 can be manufactured in the same way as prior art cathodes. exist figure 1 Among them, in particular, it is a heating coil capable of emitting electrons E due to the thermionic effect.

[0029] On the contrary, similar to the anodes of the prior art, the anode 5 of the present invention is made of a material capable of emitting X-rays wh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap