Stacked secondary battery

A secondary battery, laminated technology, applied in the direction of secondary batteries, secondary battery manufacturing, large flat batteries/batteries, etc., can solve the problems that battery components cannot enter the battery shell, battery components become thicker, and energy density decreases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

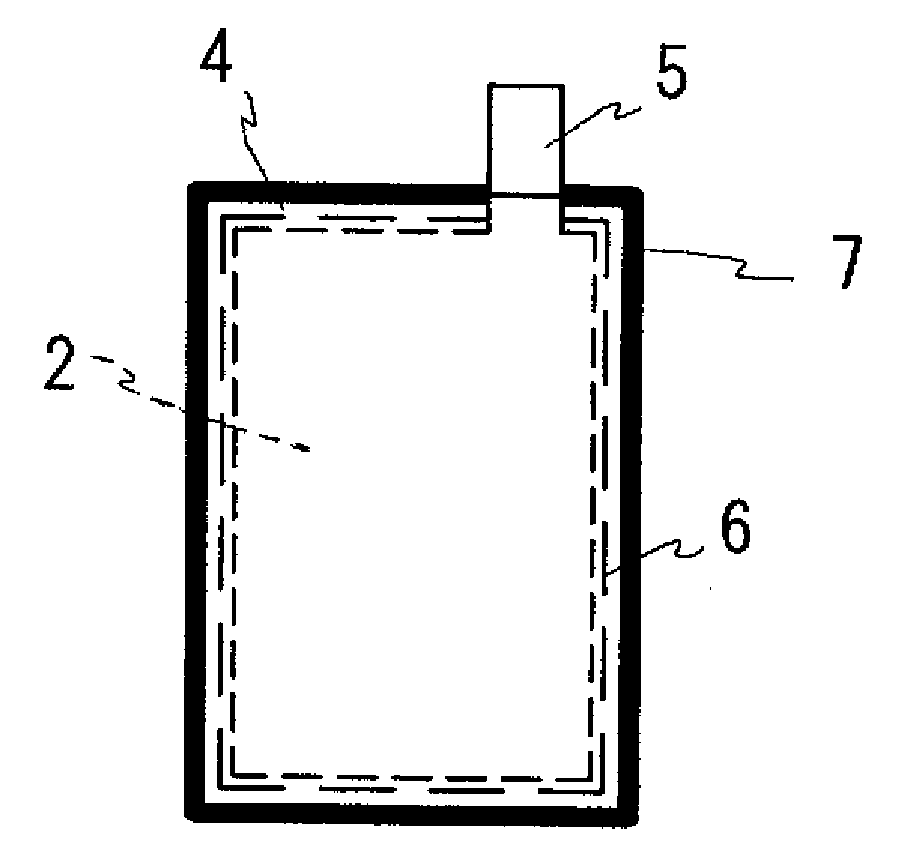

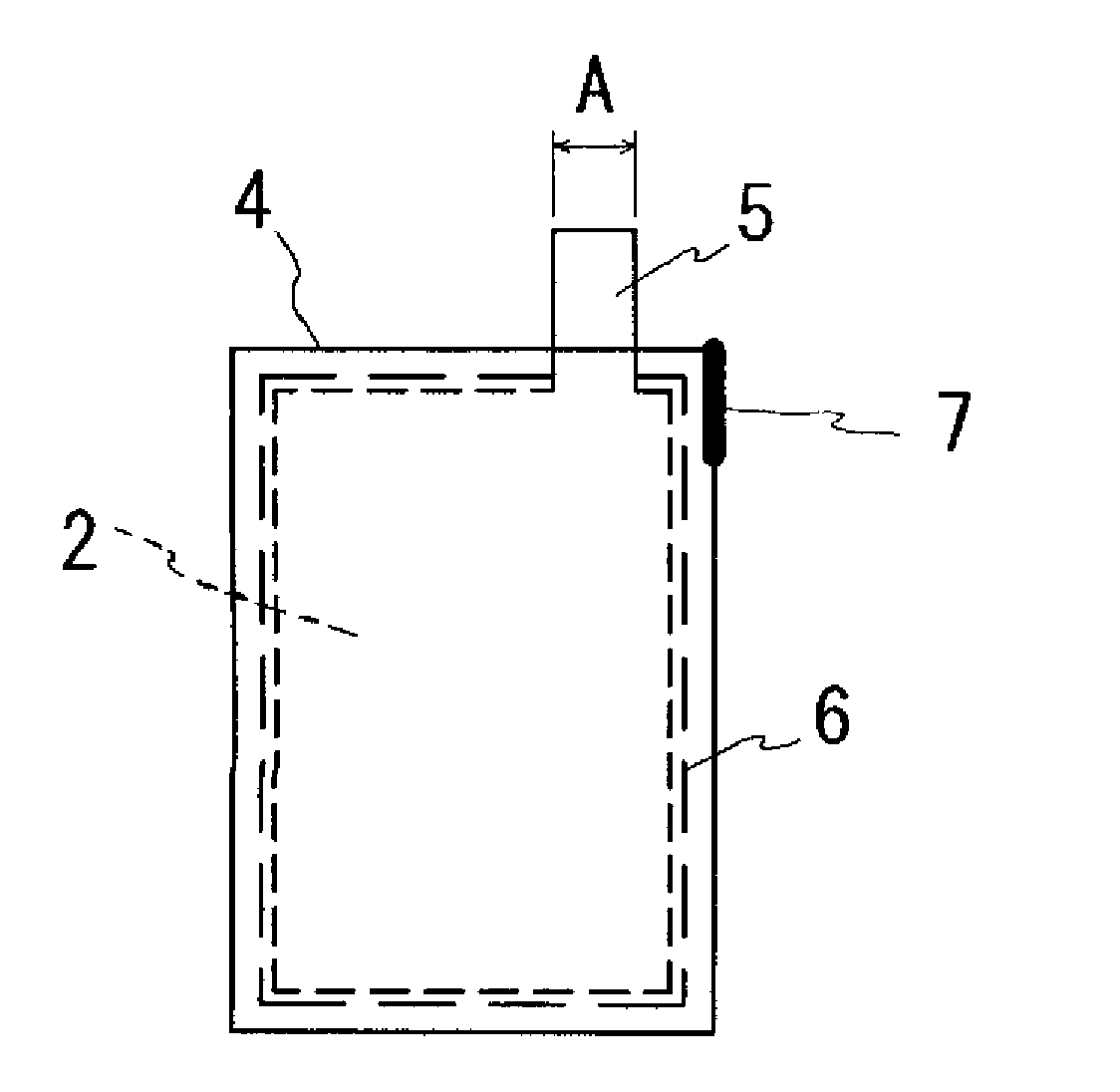

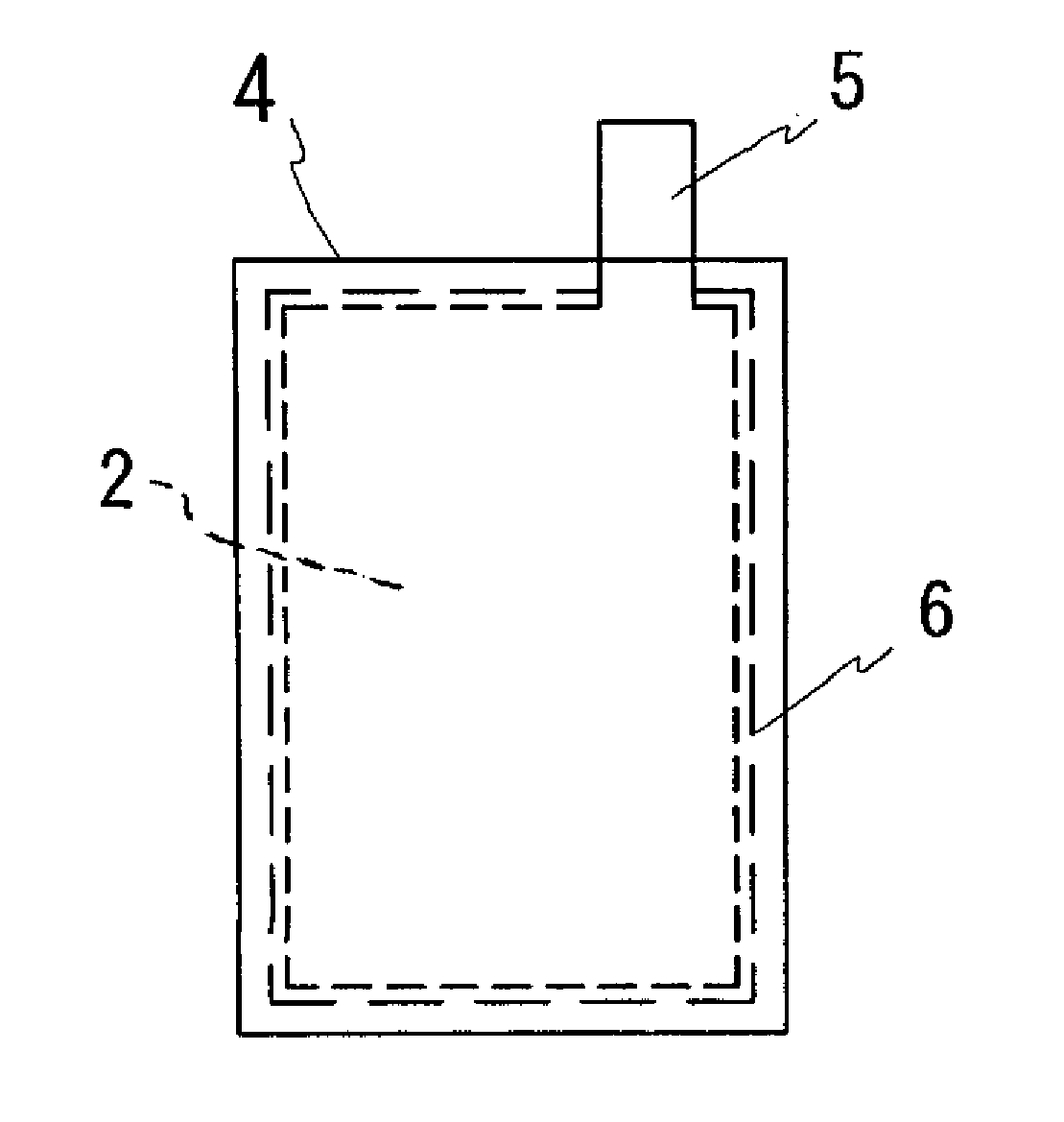

[0071] The electrode adhesive layer was coated on both sides of a rectangular aluminum foil having a longitudinal length of 94 mm, a lateral width of 64 mm, and a thickness of 20 μm, thereby producing a positive electrode. A current collector tab having a longitudinal length of 30 mm and a lateral width of 10 mm was welded to one short side of the positive electrode.

[0072] The electrode adhesive layer was coated on both sides of a rectangular copper foil having a longitudinal length of 100 mm, a lateral width of 70 mm, and a thickness of 10 μm in order to produce a negative electrode. A collector tab having a longitudinal length of 30 mm and a lateral width of 10 mm was welded to one short side of the negative electrode.

[0073] Thereafter, a plurality of positive electrodes are arranged at predetermined intervals between two belt-shaped separators each having a length of 105 mm. The belt-shaped separators are welded and joined together at intervals along the outer periphery o...

specific example 2

[0081] Except that the negative electrode was not covered with the bag-shaped separator, 50 laminated secondary batteries were produced in the same manner as in the foregoing Specific Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com