Channel device of cane harvester

A channel device and harvester technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of inability to drain cane leaves, power consumption, inconvenience in inspection and maintenance of channel devices, etc., so as to facilitate detection and maintenance of channels. The effect of reducing the power consumption of the whole machine and reducing the impurity rate of the cane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

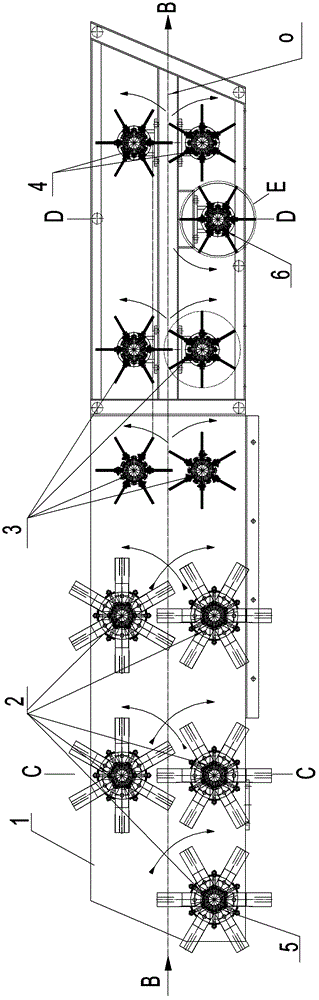

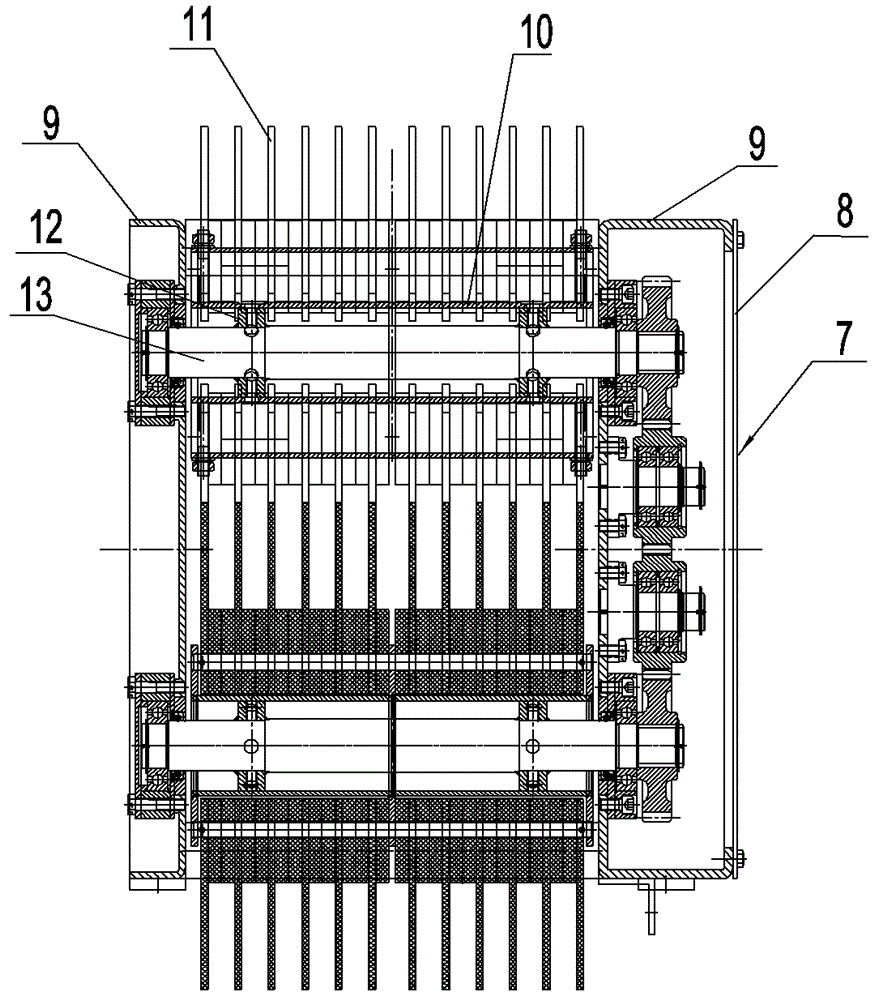

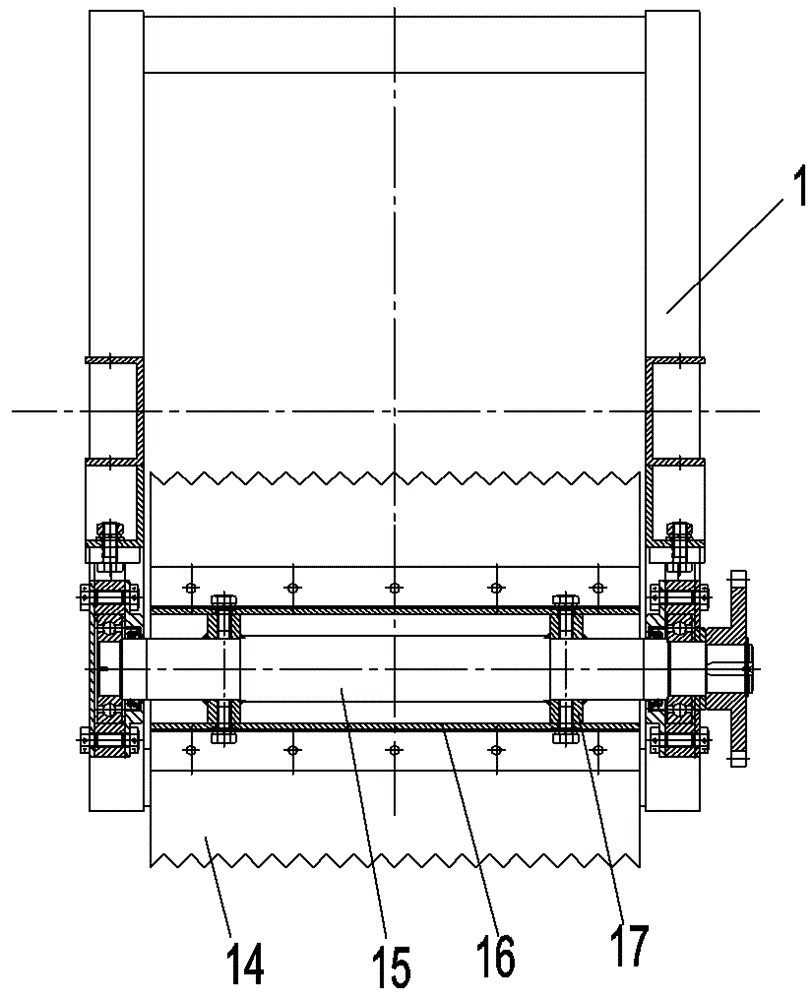

[0030] Such as Figure 1 to Figure 9 Shown, the passage device of sugarcane harvester of the present invention, this passage device comprises, stripping leaves and cutting tail device 2, speed limiting device 3, reverse leaf discharge device 6, conveying device 4, side plate integral gear box 7, power input bevel gear Box 21, sprocket 25 and chain 26 for power transmission. figure 1 The direction indicated by middle arrow B is the sugarcane conveying direction, and the curved arrows in each figure represent the turning direction of each roller.

[0031]The channel side plates 1 are located on both sides of the channel, and the tops of the two channel side plates 1 are connected with a metal cover plate 27 for closing the upper part of the channel. The channel side plates 1 and metal cover plates 27 on both sides form a channel with a closed top and an open bottom. The cavity allows the stripped sugarcane leaves to fall freely and cover the sugarcane perennial roots. The metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com