Multifunctional threshing awner

A multi-functional, thresher technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of short distance transportation of rice and wheat grains, cumbersome processing procedures, long processing time, etc., and achieve short-distance movement convenient and fast , The effect of reducing processing time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

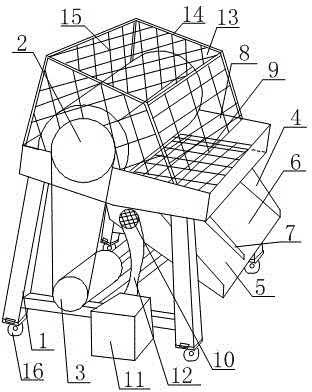

[0027] Such as figure 1 As shown, the multifunctional threshing and awning machine includes a frame 1, a thresher 2 installed on the upper part of the frame 1, a motor 3 installed on the lower part of the frame 1 and connected to the thresher 2, and the thresher 2 is provided with a discharge Port 4, the upper part of the discharge port 4 is provided with an awning bucket 8, and the bottom side of the internal bottom of the awning bucket 8 is provided with an awning net 9, and a secondary screening device is also provided on the side wall of the discharge port 4, above the threshing machine 2 Also be provided with the anti-splash net 13 that is connected with frame 1, for the convenience of ventilation and observation, described anti-splash net 13 is made up of support 14 and cover net 15, and wherein cover net 15 is made by gauze or steel wire netting, in order to facilitate Disassembly, the bracket 14 is connected with the frame 1 by screws. When the thresher is placed, tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com