A cylindrical hole honing head device and its construction method

A construction method and honing head technology, applied in the direction of honing tools, etc., can solve the problems that are not involved, and achieve the effects of increasing the number, uniform trajectory distribution, and uniform honing and grinding of cylinder hole wall materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

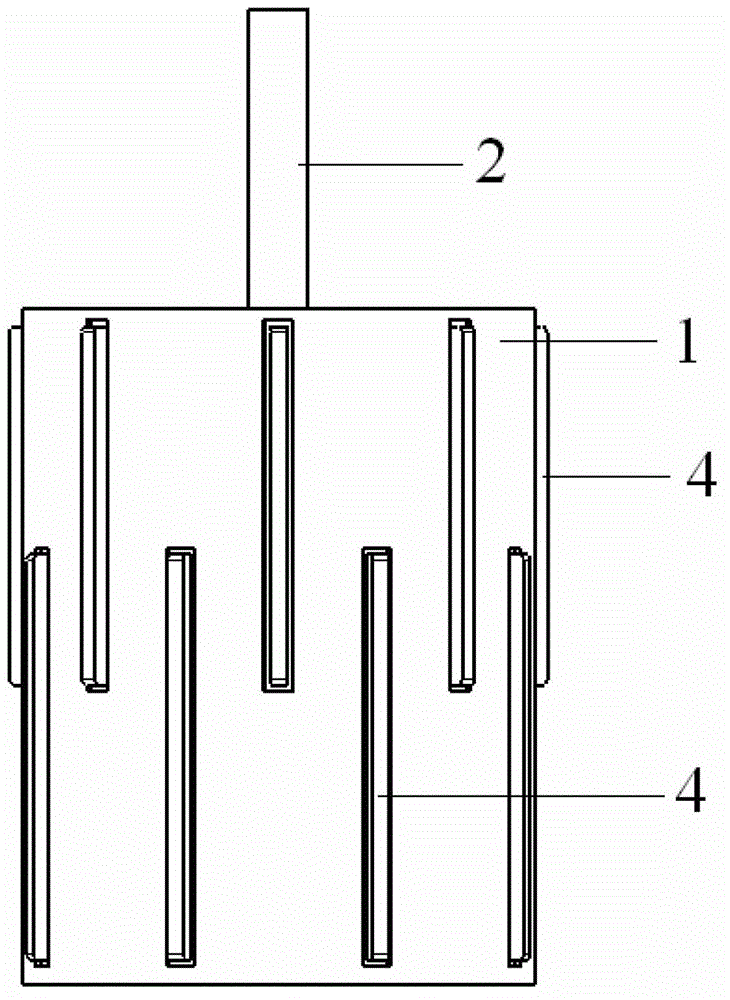

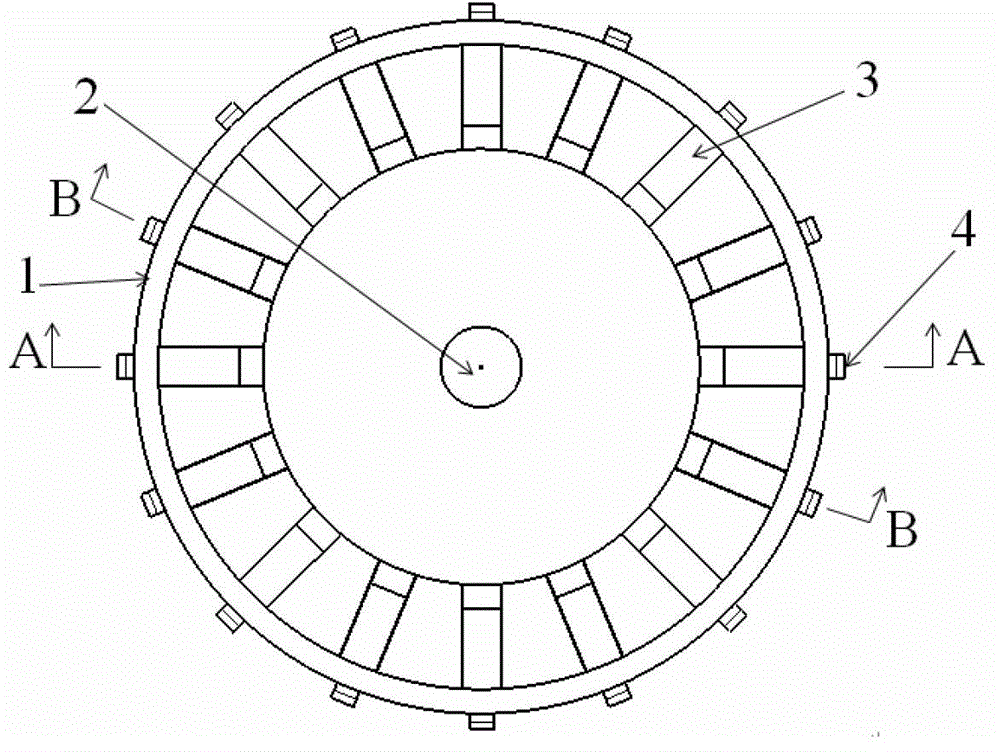

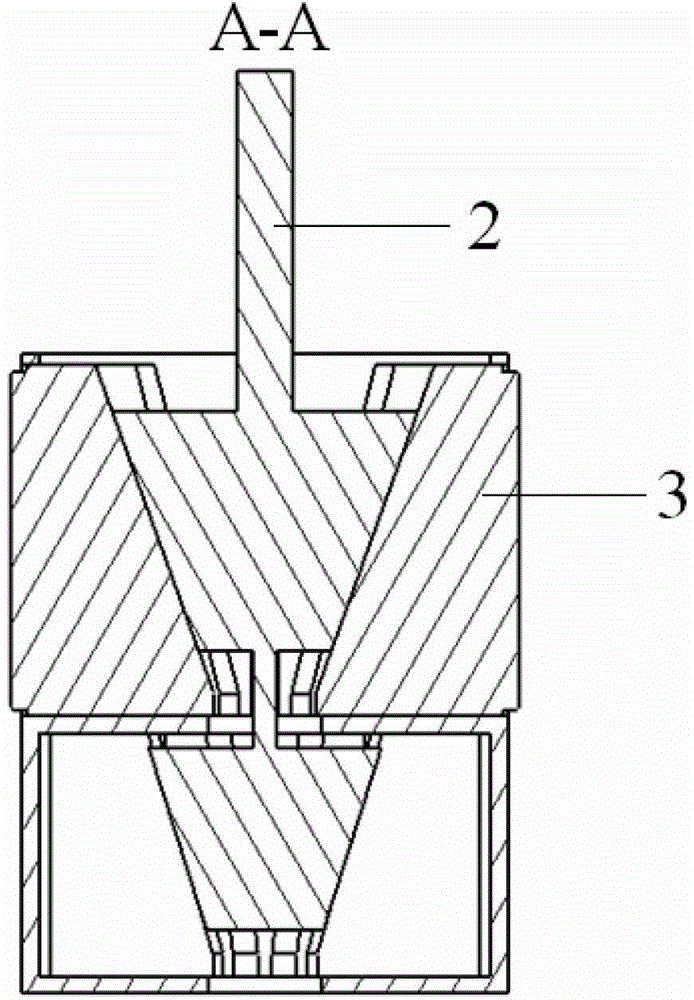

[0040] An ideal cylindrical hole honing head device, its structure is as follows Figure 1-4 As shown, the device includes a grinding head frame 1, a feed rod 2, a whetstone base 3 and a whetstone 4. Wherein, the grinding head frame 1 is a hollow cylindrical structure, and base holes are arranged alternately in the circumferential direction of the grinding head frame 1. There are two rows of base holes, and the adjacent base holes are arranged alternately up and down. The feed rod 2 has a conical structure and is located at the center of the grinding head frame 1 . The oil stone base 3 is installed in the base hole and can slide along the guide groove of the base hole. The whetstone base 3 used is a wedge-shaped block, and the inclined surface on the inside fits the tapered surface of the feed rod 2 . The oil stone 4 is fixed on the oil stone base 3, and the oil stone 4 used is a sand bar.

[0041] The following steps are used in the construction of the ideal cylindrical ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com