Deoxidizing device for electron beam printing and deoxidizing method thereof

A technology of deoxidizing equipment and electron beam, applied in printing, printing machine, general parts of printing machinery, etc., can solve the problem of high cost, and achieve the effect of strong market competitiveness and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: A film sticking device for sheet-fed paper.

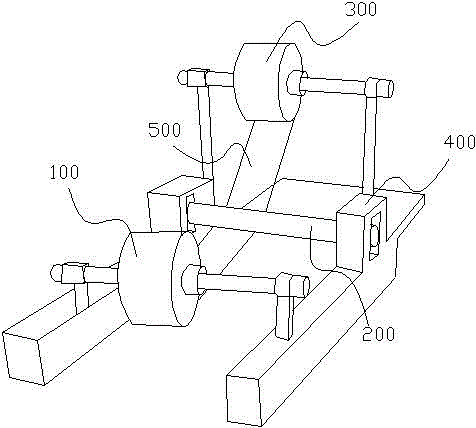

[0048] see image 3 , which is a schematic diagram of the first embodiment of the electron beam printing oxygen removal equipment of the present invention. In this embodiment, the oxygen removal device is a film sticking device, which is used to attach a film to the ink on the substrate, so that the ink on the substrate is isolated from the air when the electron beam is solidified. In this way, the ink on the substrate is isolated from the air when the electron beam is cured, and the film is separated from the substrate after curing. The cost is low and the implementation is relatively simple. Such as image 3As shown, the film sticking device includes a transmission wheel 100, a cylinder 200, a winding wheel 300 and a support 400, and the transmission wheel 100, the winding wheel 300 and the cylinder 200 are arranged on the support 400; the transmission wheel 100 wraps the film 500 Transfer to the electron ...

Embodiment 2

[0055] Embodiment 2: A film sticking device for roll paper.

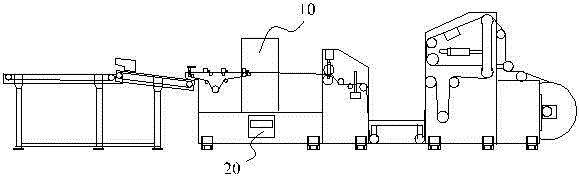

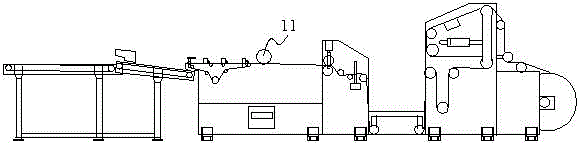

[0056] Its basic implementation method is the same as that of the sheet-fed production equipment, so it will not be repeated here. It should be noted that when the roll paper production equipment produces the roll paper, a stretching force is generated on the roll paper through the conveying equipment (see figure 1 or figure 2 ), in this way, in order to ensure that the film sticking device can combine the film and the roll paper well, we need to ensure that the transmission wheel (including the winding wheel) is synchronized with the transmission of the roll paper.

Embodiment 3

[0057] Embodiment 3: Rolling device for sheet-fed paper

[0058] read on Figure 4 , which is a schematic diagram of the third embodiment of the electron beam printing oxygen removal equipment of the present invention. In this embodiment, the deoxygenation device is a rolling device, which is used to isolate the ink on the substrate from the air by fully contacting the rolling device with the ink on the substrate. This method of isolating the ink on the substrate from the air by rolling has a better insulation effect and fully meets the requirements of electron beam curing. Such as Figure 4 As shown, the rolling device includes a roller 600 and a transmission shaft 700, the roller 600 is arranged on the transmission shaft 700, and is located above the electron beam curing position; when the ink on the substrate is at the electron beam curing position, the The transmission shaft 600 drives the roller 700 to rotate, so that the roller 700 is fully in contact with the ink on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com