Energy-feedback active control type air braking system

A technology of active control and pneumatic braking, which is applied in the direction of hydraulic brake transmission, brake, brake transmission, etc., can solve the problems of insufficient braking energy recovery, affecting braking performance, and inability to control separately, so as to achieve transformation The effect of low cost and difficulty of realization, ensuring braking stability and reducing braking hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

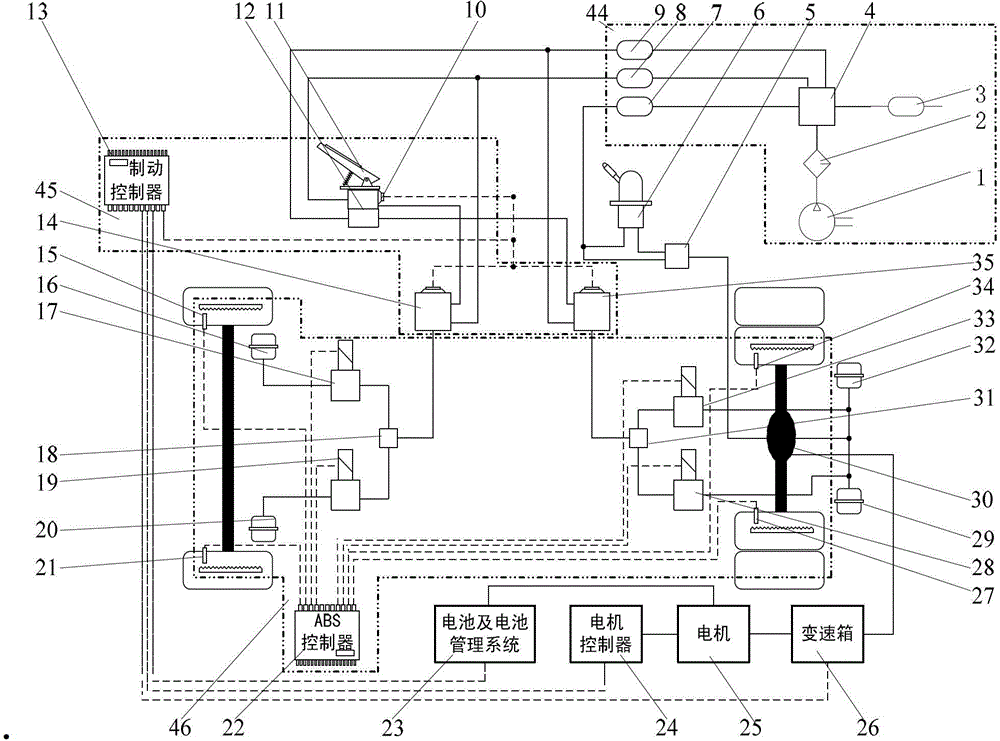

[0032] Such as figure 1 As shown, an energy feedback active control air brake system of this embodiment includes three modules: a high-pressure air pressure generating module 44, an air pressure active control module 45, and an ABS module 46.

[0033] The high-pressure gas generating module 44 is used to generate high-pressure gas for the entire vehicle under a certain pressure, and the certain pressure refers to a pressure range between 0.7 MPa and 1.1 MPa. The high-pressure gas generating module 44 includes an air compressor 1, an air storage tank 2, a four-circuit protection valve 4, an air bag cylinder 3, a parking tank 7, a front axle air tank 8, and a rear axle air tank 9. The air compressor 1 is connected to the input port of the air storage tank 2, the output port of the air storage tank 2 is connected to the input port of the four-circuit protection valve 4, and the output port of the four-circuit protection valve 4 is connected to the air bag cylinder 3 and the parking t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com