Liquid bottle cap with silica gel valve compressing plunger

A silicone valve and plunger technology, which is applied in the field of container sealing cover structure, can solve the problems of easy opening and liquid can not seep out, etc., and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

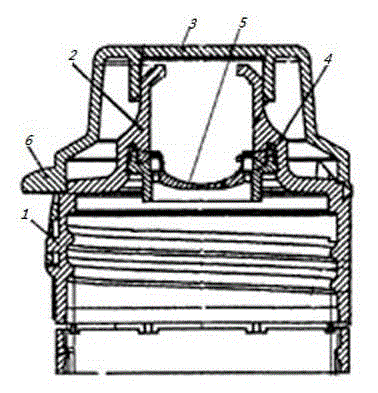

[0017] Embodiment 1: A liquid bottle cap with a compressed silicone valve plunger, including: a bottle cap body 1, a drinking spout 2, a bottle cap cap 3, a valve seat 4 and a silicone valve 5, and the upper part of the bottle cap body 1 is protruding The drinking spout 2, the bottle cap 3 is buckled on the drinking spout 2, the drinking spout 2 is provided with a valve seat 4, the silicone valve 5 is inlaid on the valve seat 4 around, the silicone valve 5 is a silicone gasket with an opening in the middle, and the drinking spout There is a plunger 7 in the mouth 2, and the lower end surface of the plunger 7 is close to the upper surface of the silica gel valve 5 to prevent the liquid in the bottle from penetrating the silica gel valve.

[0018] In Embodiment 1, the shape of the plunger can be any shape that can prevent the liquid in the bottle from entering the drinking spout 2, and the lower end surface of the plunger 7 is in the shape of a straight line or a cross;

[00...

Embodiment 2

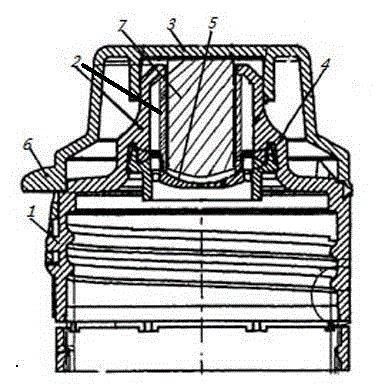

[0020] Embodiment 2: A liquid bottle cap with a compressed silicone valve plunger, including: a bottle cap body 1, a drinking spout 2, a bottle cap cap 3, a valve seat 4 and a silicone valve 5, and the upper part of the bottle cap body 1 is protruding The drinking spout 2, the bottle cap 3 is buckled on the drinking spout 2, the drinking spout 2 is provided with a valve seat 4, the silicone valve 5 is inlaid on the valve seat 4 around, the silicone valve 5 is a silicone gasket with an opening in the middle, and the drinking spout There is a plunger 7 in the mouth 2, and the lower end surface of the plunger 7 is close to the upper surface of the silica gel valve 5 to prevent the liquid in the bottle from passing through the silica gel valve, and the opening in the middle part of the silica gel valve 5 is an incision.

[0021] In embodiment 2, if the opening in the middle part of the silicone valve 5 is preferably a vertical cut, it is ensured that the silica gel on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com