Carrying cart for storage shelf

A technology for carrying trolleys and shelves, applied in the field of storage equipment, can solve problems affecting work efficiency and poor stability, and achieve the effects of convenient assembly, simple operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are further described below in conjunction with the drawings:

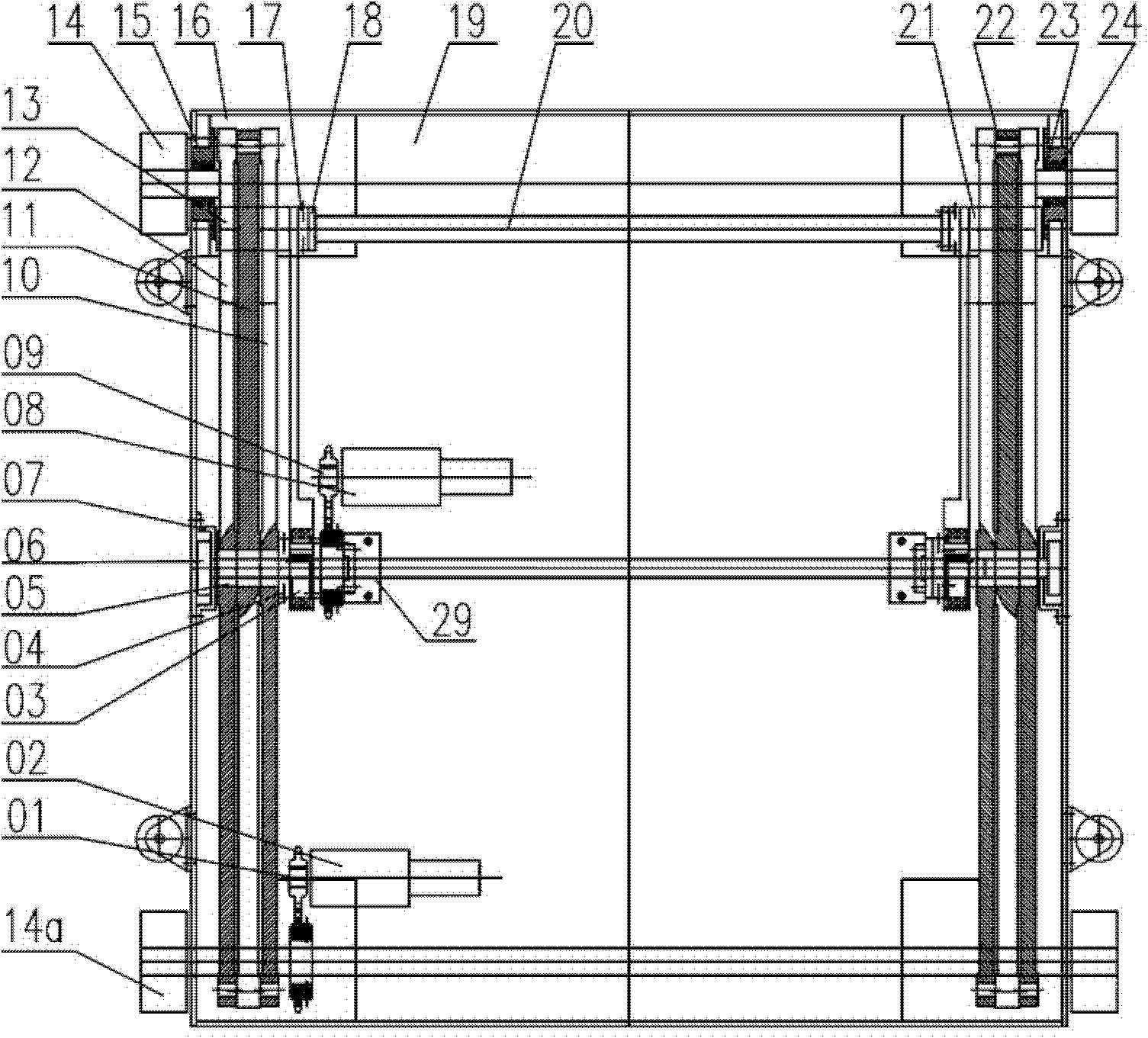

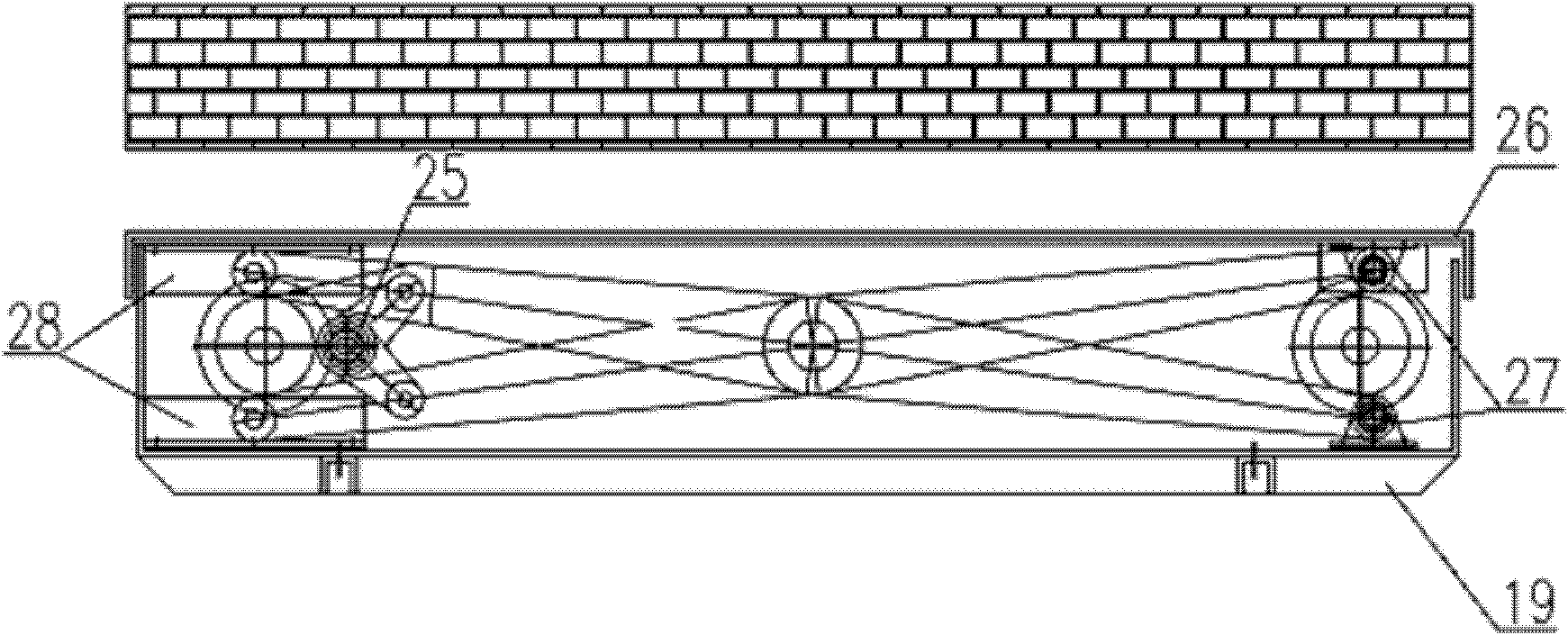

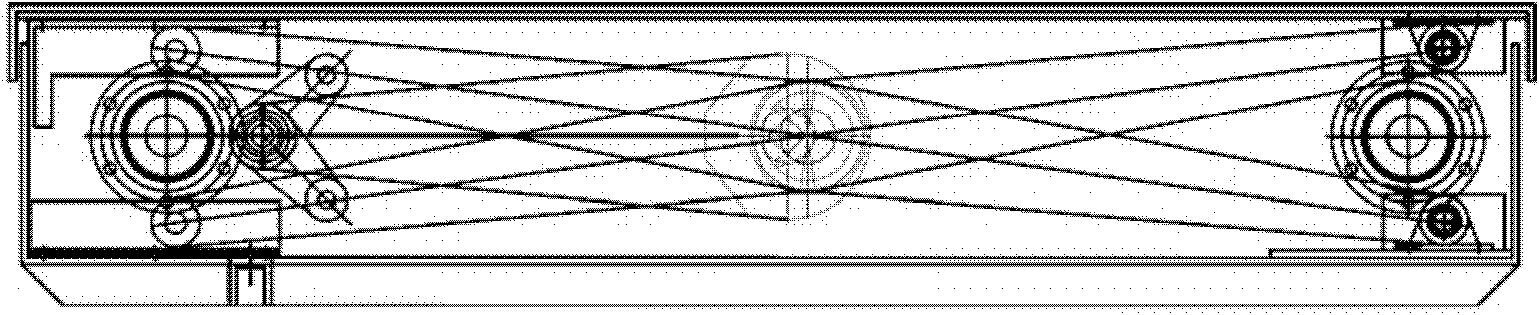

[0017] See figure 1 , figure 2 , The present invention is composed of a car body 19, a car cover 26, a walking mechanism for the carriage to move on the sliding rail of the storage shelf, and a lifting mechanism for the lifting of the carriage. The traveling mechanism includes: driving motor 2, sprocket 1, driven wheel 14, and driving wheel 14a. The lifting mechanism includes: lifting motor 8, hinge 10, hinge 11, hinge 12, small hinge 25, eccentric link 3, key shaft sleeve 5. Key shaft 6, positioning bracket 7, sprocket mechanism 9, shaft 20, bracket 27, sliding groove 28, positioning bracket 29. The driving motor 2 is driven by the sprocket 1, the driving wheel 14a, and the driven wheel 14. The driving wheel 14a drives the car body 19 to travel on the slide rail of the storage shelf under the control of the control device. The hinge 10, the hinge 11, and the hinge 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com