Belt conveyor longitudinal tear detector and detection method

A belt conveyor, longitudinal tearing technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of inability to apply belt detection, reduce belt strength, misjudgment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

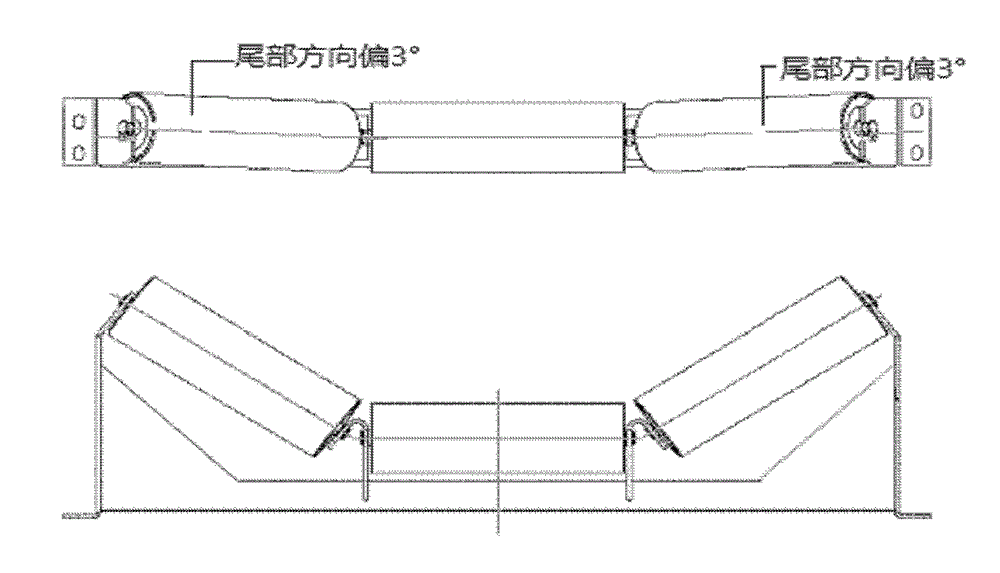

[0032] Below, combined with Figure 1-3 To further describe the present invention in detail.

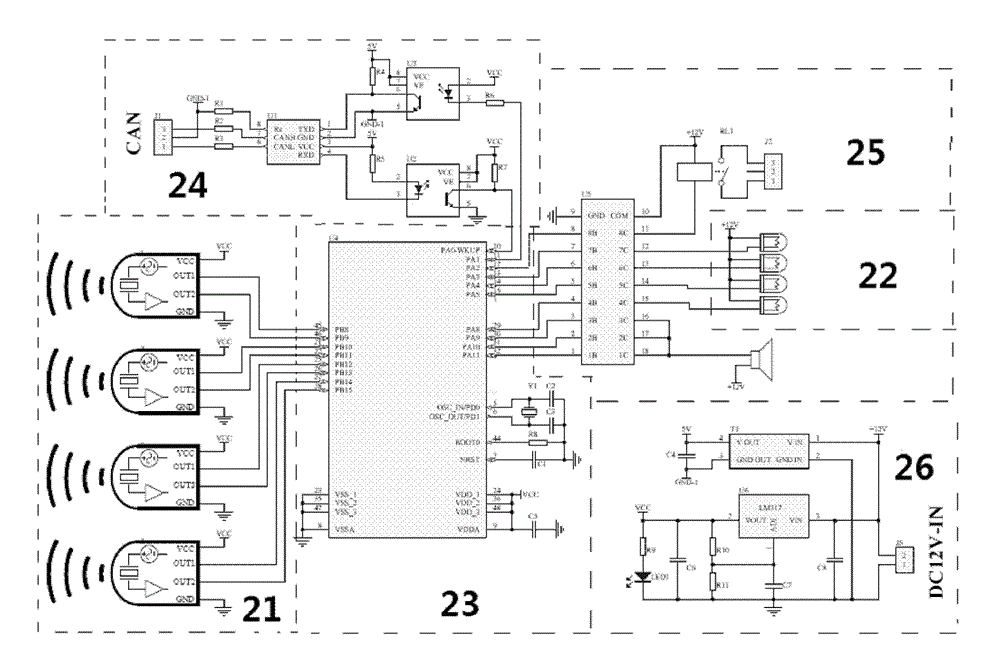

[0033] figure 1 It is the schematic circuit diagram of the ultrasonic sensor and the data processing unit of the embodiment of the present invention. It includes four ultrasonic sensors 21 for measuring the width of the upper and lower belts, four laser emitting units 22 for positioning, a microprocessor unit 23, a communication conversion drive circuit 24, an alarm and control unit 25 and a power supply circuit 26.

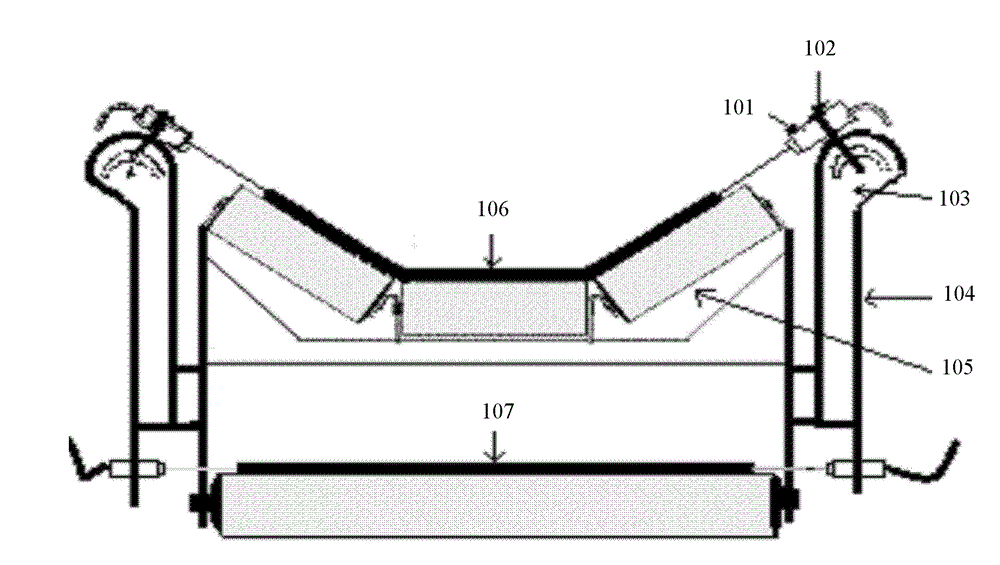

[0034] figure 2 The ultrasonic sensor installation and measurement method of the embodiment of the present invention are given. figure 2 Among them, 101 is an ultrasonic sensor; 102 is a positioning laser head; 103 is a sensor angle adjustment bracket; 104 is a sensor height adjustment bracket; 105 is a belt deflection adjustment bracket; 106 is an upper belt; 107 is a lower belt. Among the four ultrasonic sensors, two are installed on both sides of the upper belt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com